Size tank sizing device and method applied to sizing machine and warping and sizing machine

A technology for sizing machines and sizing tanks, which is applied in the processing of textile materials, equipment configuration, liquid/gas/steam yarn/filament processing, etc., and can solve the problems of increased sizing rate of secondary sizing, increased concentration and viscosity, concentration and Viscosity and other problems, to achieve the effect of reducing the sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

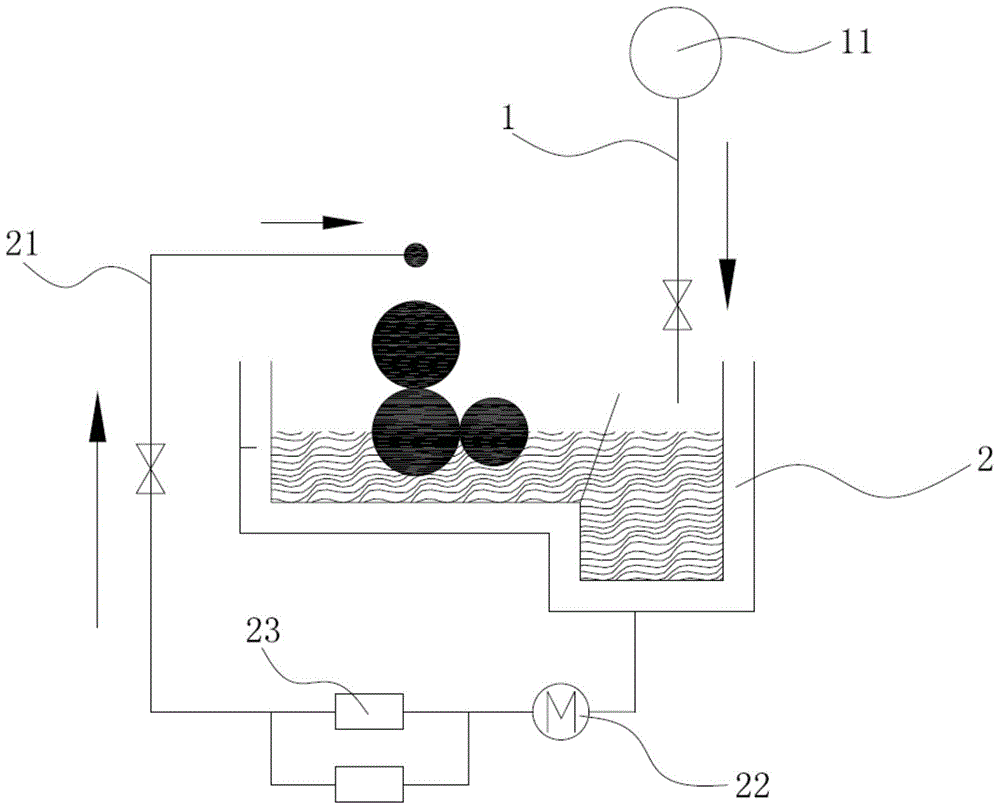

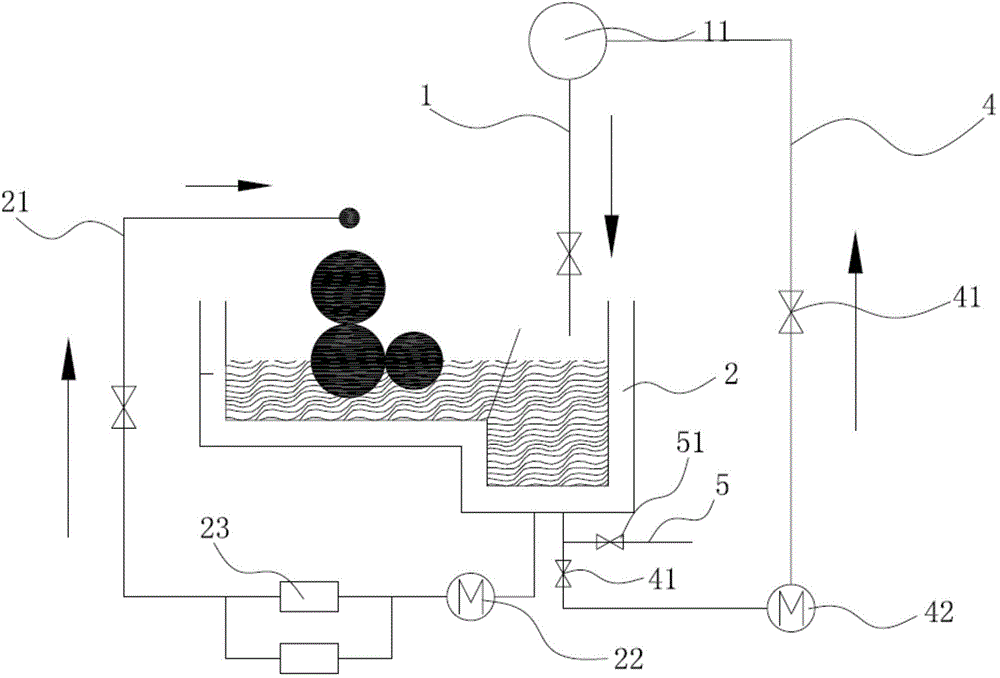

[0036] In order to achieve the purpose of the present invention, as figure 2 As shown, in some embodiments of the sizing tank sizing device applied to the sizing machine and the sizing machine of the present invention, it is installed at the size tank 2, and the device includes: a slurry source 11; a sizing pipe 1, one end of which is It is connected to the pulp source 11, and the other end extends into the pulp tank 2; one end of the return pipe 4 is connected to the pulp source 11, and the other end is connected to the inside of the pulp tank 2. The slurry is extracted into the slurry source 11. Others such as the slurry pipe 21 , the motor 22 and the filter 23 are the same as those of the prior art, and will not be repeated here.

[0037] This device adds a slurry return pipe connecting the slurry tank and the slurry source on the basis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com