Novel walking type chassis crawler shoe structure

A walking and booting technology, which is applied in the direction of infrastructure engineering, drilling equipment, drilling equipment and methods, etc., can solve problems such as the impact of service life, skewing of the axis of the walking cylinder, troublesome assembly, etc., and achieve the improvement of load carrying capacity, The structure of the shoe is stable and the assembly is easy to improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

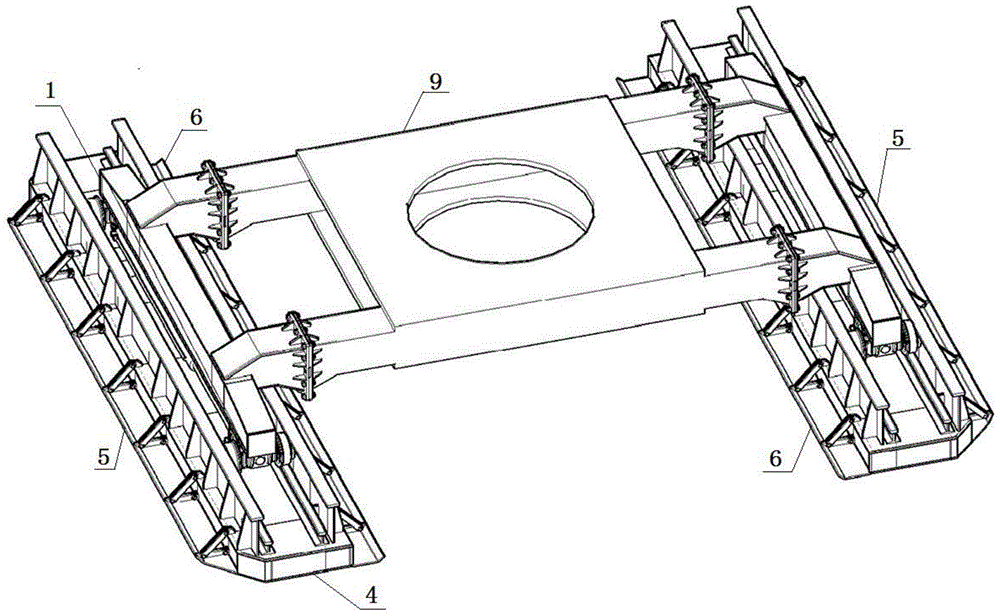

[0030] Such as figure 1 As shown, the new walking chassis shoe structure is mainly composed of two sets of parallel traveling mechanisms and a walking frame 9, the mechanical equipment is fixed on the walking frame, and the two ends of the walking frame are respectively connected with the two groups of walking mechanisms through pivot pins.

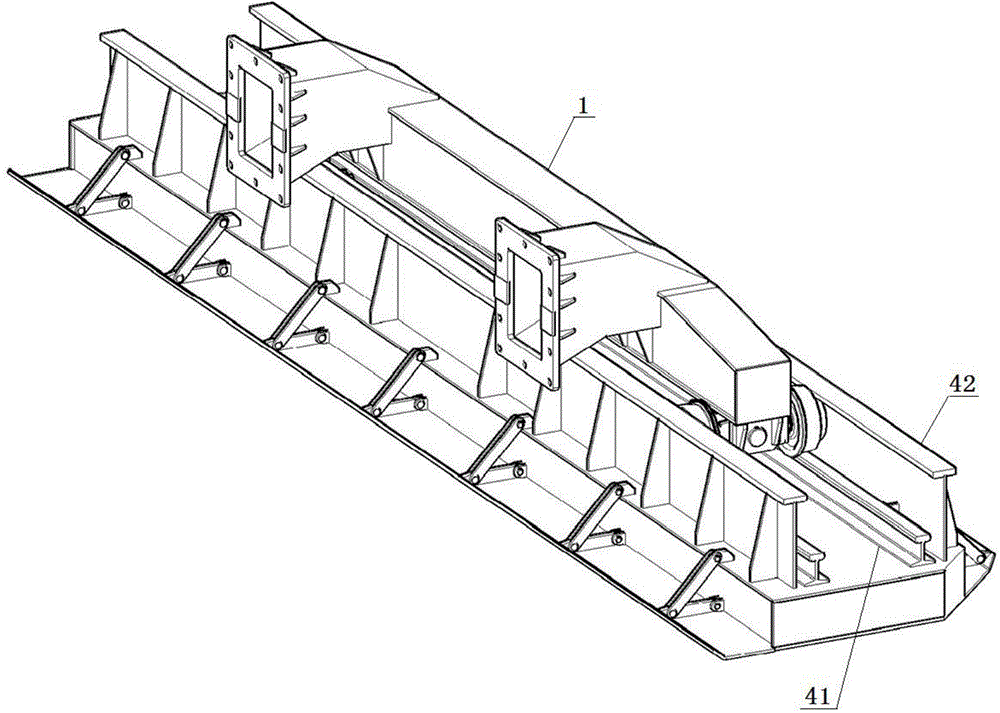

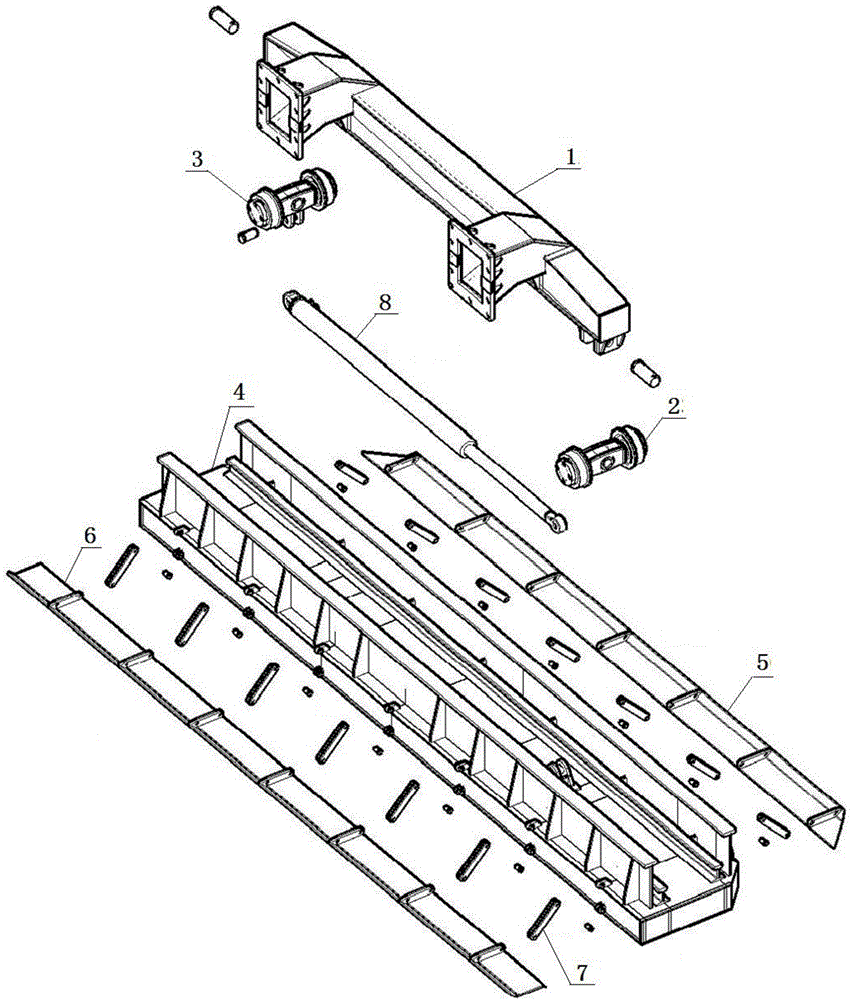

[0031] Such as Figure 2 to Figure 5 As shown, the traveling mechanism mainly includes a traveling wheel beam 1, a front traveling wheel group 2, a rear traveling wheel group 3, shoe shoes 4 and a traveling oil cylinder 8, and the traveling mechanism also includes an outer hanger 5, an inner hanger 6 and a pull rod 7 .

[0032] The outer hanger 5 and the inner hanger 6 are respectively arranged on the inner side and the outer side of the shoe 4 through the foldable tie rod 7; The wall is welded on the top wall of the external hanger or inner hanger in a vertical manner; the end of the tie rod away from the shoe shoe and one end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com