A magnetic thrust combined bearing for an underwater generator

A magnetic bearing and combined bearing technology, applied in ball bearings, bearing components, shafts and bearings, etc., can solve problems such as difficult and reliable work for a long time, and achieve the effect of avoiding demagnetization risks, reducing non-axial runout and reducing power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

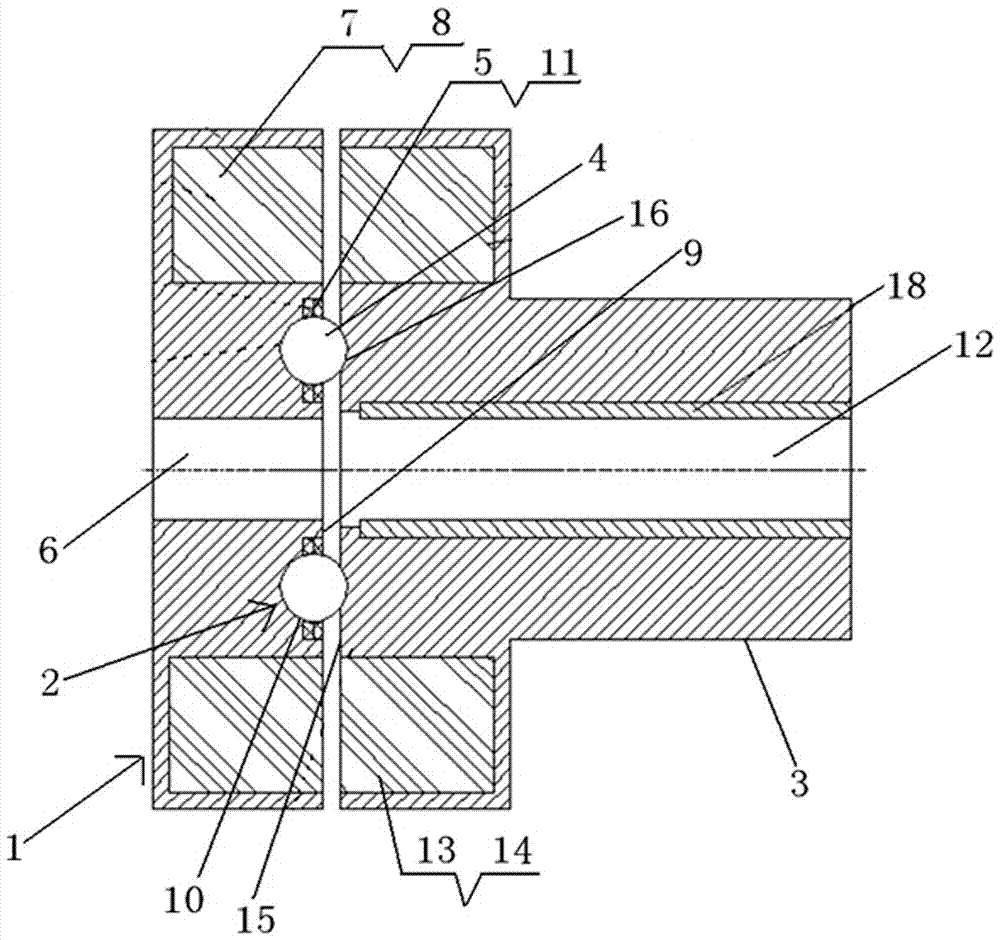

[0020] A magnetic thrust combination bearing for an underwater generator, comprising a magnetic bearing seat A1, a self-lubricating POM ball bearing group 2 and a magnetic bearing seat B3, characterized in that:

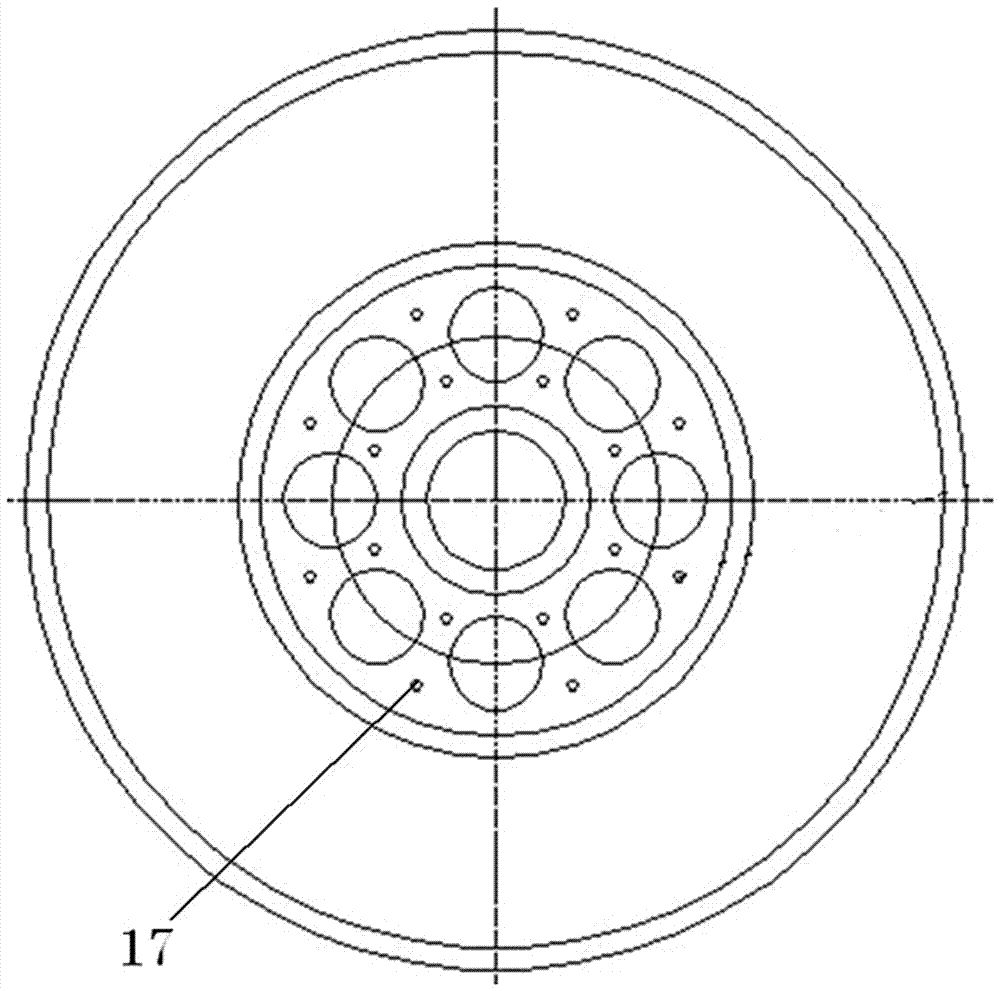

[0021] The self-lubricating POM ball bearing set 2 includes a plurality of POM balls 4 and a retainer 5 , and the plurality of POM balls 4 are installed in a corresponding pocket of the retainer 5 .

[0022] There is a first shaft hole 6 in the middle of the magnetic bearing seat A1, a first annular groove 7 is formed on the rear end surface of the magnetic bearing seat A1, and a first magnetic ring 8 is installed in the first annular groove 7 . There is a first annular raceway 10 and a cage groove 11 on the first annular end surface 9 at the rear end of the magnetic bearing A1.

[0023] There is a second shaft hole 12 in the middle of the magnetic bearing seat B3, a second annular groove 13 is arranged on the front end surface of the magnetic bearing seat B3, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com