Temperature stratification type heat accumulating/releasing device

A technology of temperature stratification, heat storage and release, which is applied in the direction of household heating, heating methods, household heating, etc., can solve the problem that the heat storage and heat release of the heat storage device cannot be carried out at the same time, and the heat storage effect of the heat storage tank is not very good. Ideal, poor heat storage effect and other problems, to achieve the effect of reducing the mixing of hot and cold water, improving the heat storage effect, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

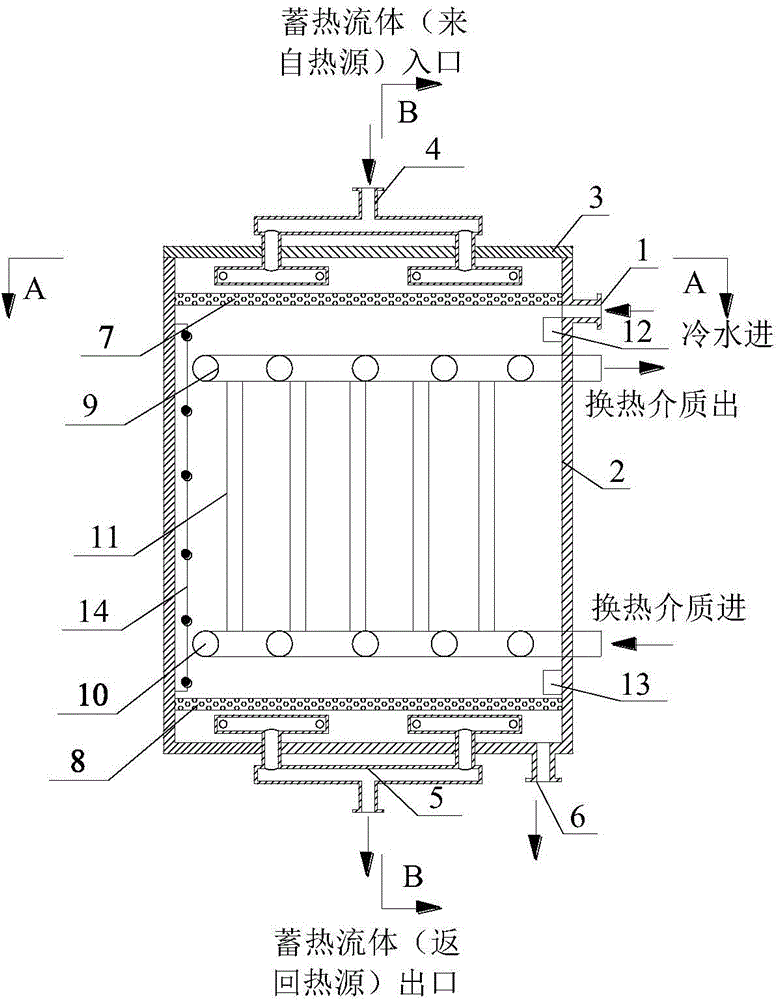

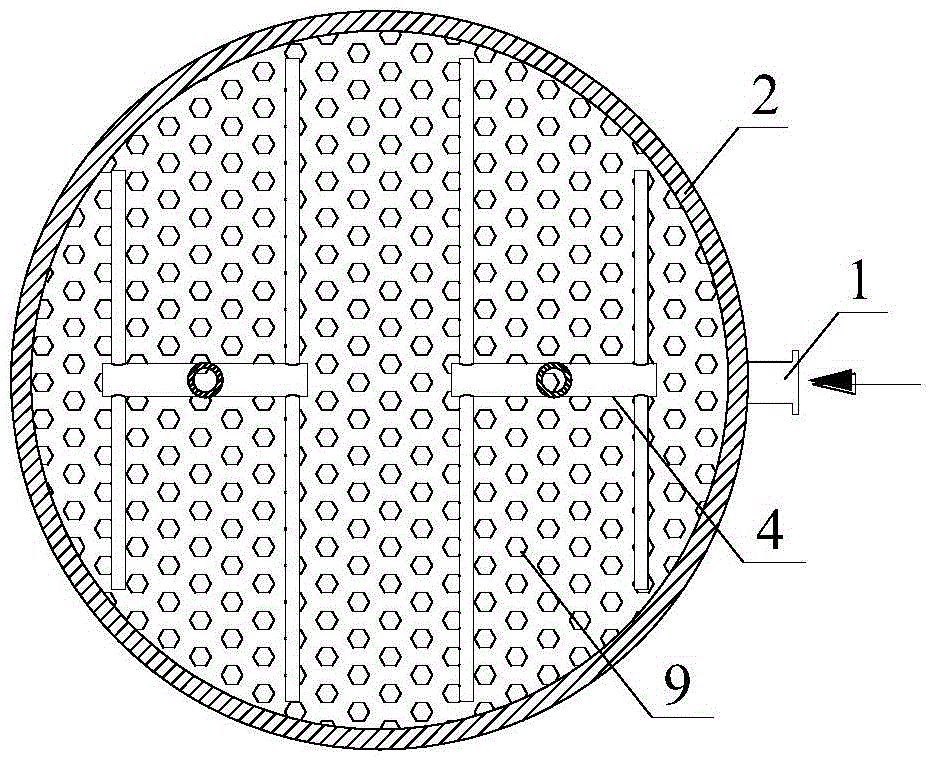

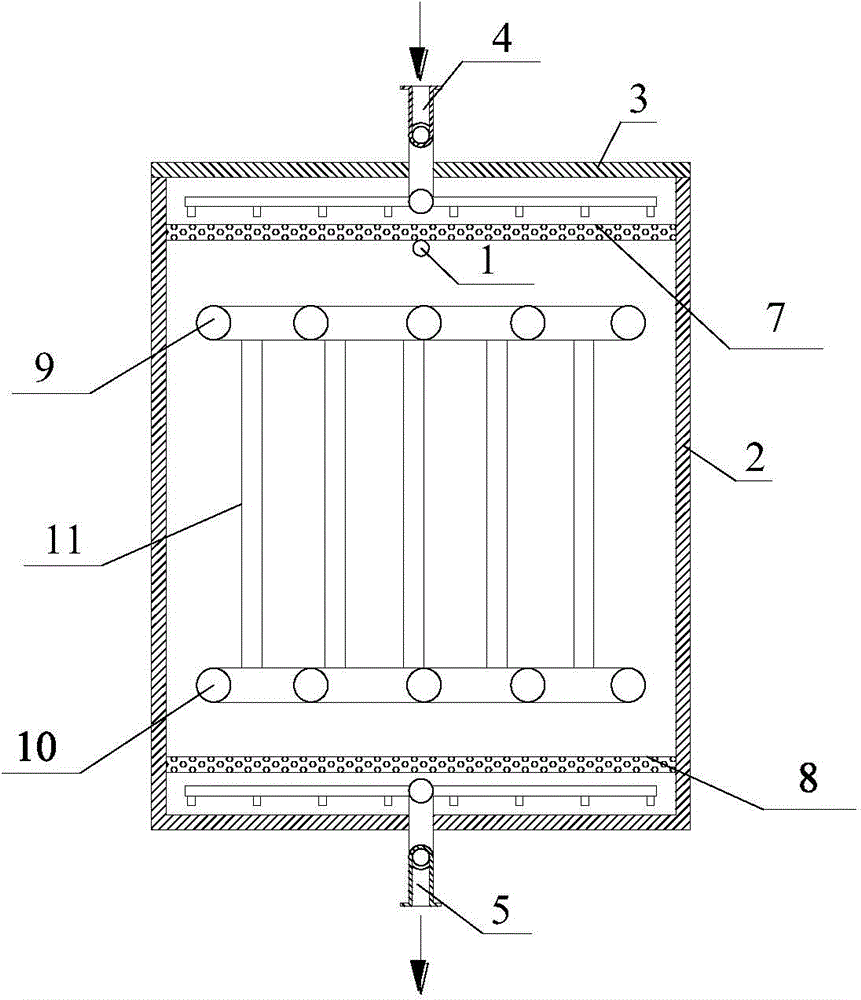

[0020] A temperature layered heat storage and release device of the present invention is mainly composed of a water inlet 1, a heat storage box body 2, a heat storage box cover 3, an inlet water distributor 4, an outlet water collector 5, a sewage outlet 6, and an upper equalizing plate 7. The lower equalizing plate 8, the heat exchange medium water collection header 9, the heat exchange medium water distribution header 10, the medium heat exchange tube 11, the highest liquid level sensor 12, the lowest liquid level sensor 13, and the liquid temperature sensor 14. Water inlet 1, heat storage tank 2, heat storage tank cover 3, inlet water distributor 4, outlet water collector 5, sewage outlet 6, upper equalizing plate 7, lower equalizing plate 8, maximum liquid level sensor 12, The lowest liquid level sensor 13 and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com