Method for processing circuit board and circuit board with single-sided annular ring

A processing method and circuit board technology, applied in the direction of multilayer circuit manufacturing, printed circuit components, electrical connection printed components, etc., to achieve the effect of improving the level of intensification, improving utilization, and saving outer space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

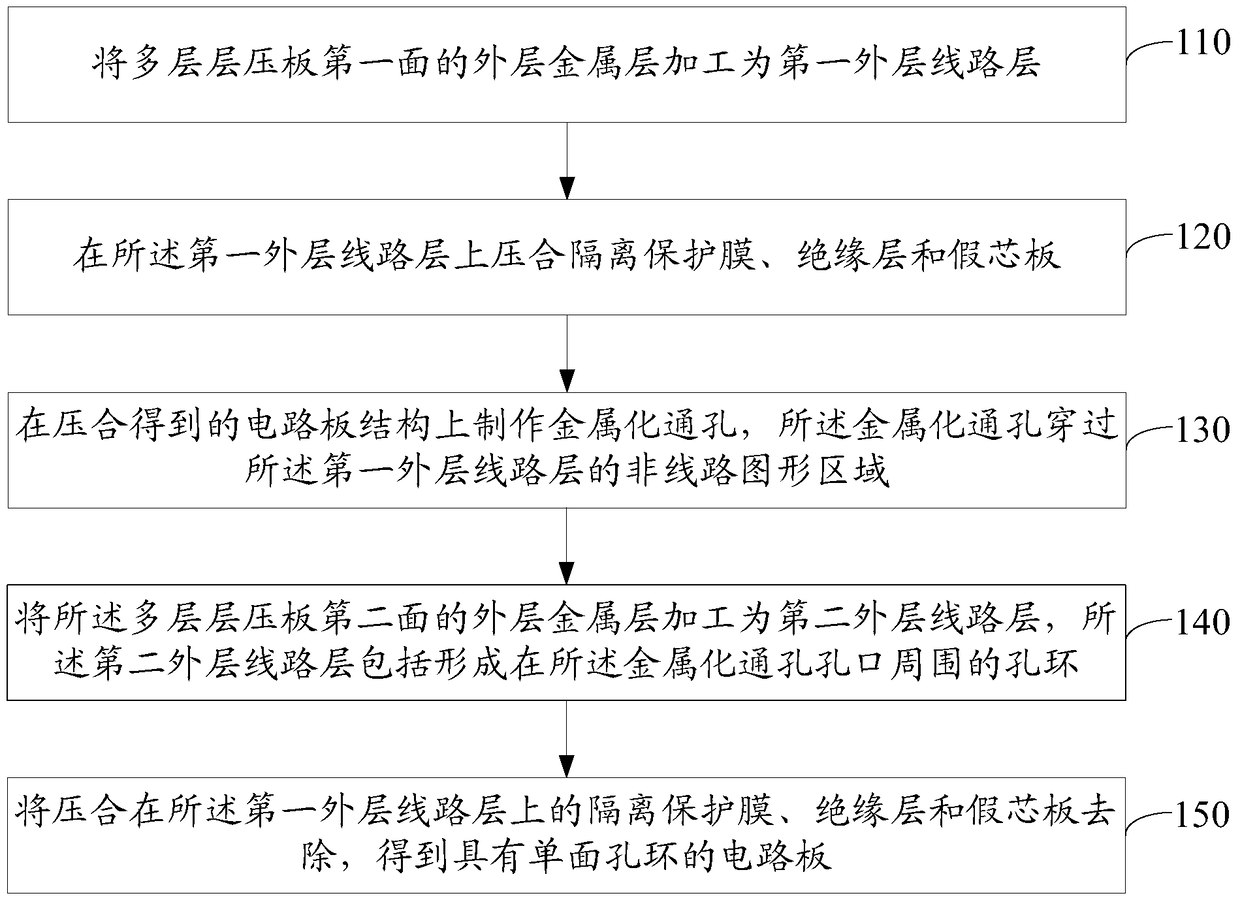

[0026] Please refer to figure 1 , an embodiment of the present invention provides a method for processing a circuit board, which may include:

[0027] 110. Process the outer metal layer on the first side of the multilayer laminate into a first outer circuit layer.

[0028] In the embodiment of the present invention, the circuit board may be a multi-layer laminate based on double-sided copper-clad laminates. Specifically, the multi-layer laminate can be laminated with one or more double-sided copper-clad laminates in the middle, directly laminated copper foil layers on both sides, and laminated an insulating adhesive layer between each layer of double-sided copper-clad laminates and copper foil layers, such as Prepreg, laminated. Among them, before lamination, the double-sided copper clad laminate has been produced with a circuit layer.

[0029] According to the method of the embodiment of the present invention, a metallized through hole with a single-sided annular ring can ...

Embodiment 2

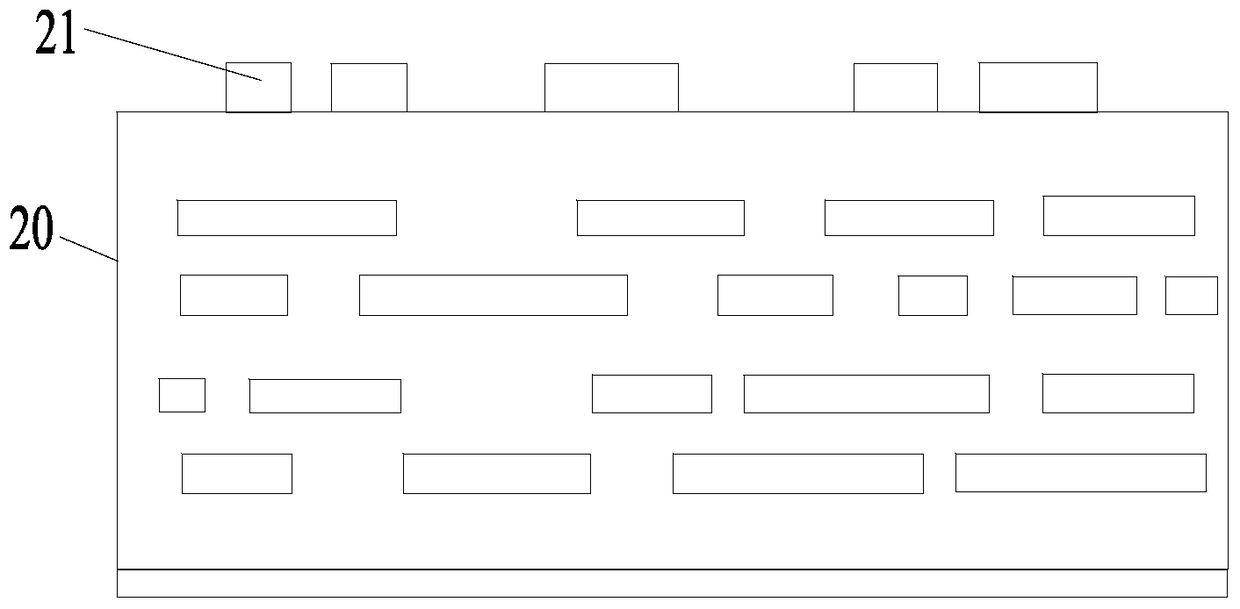

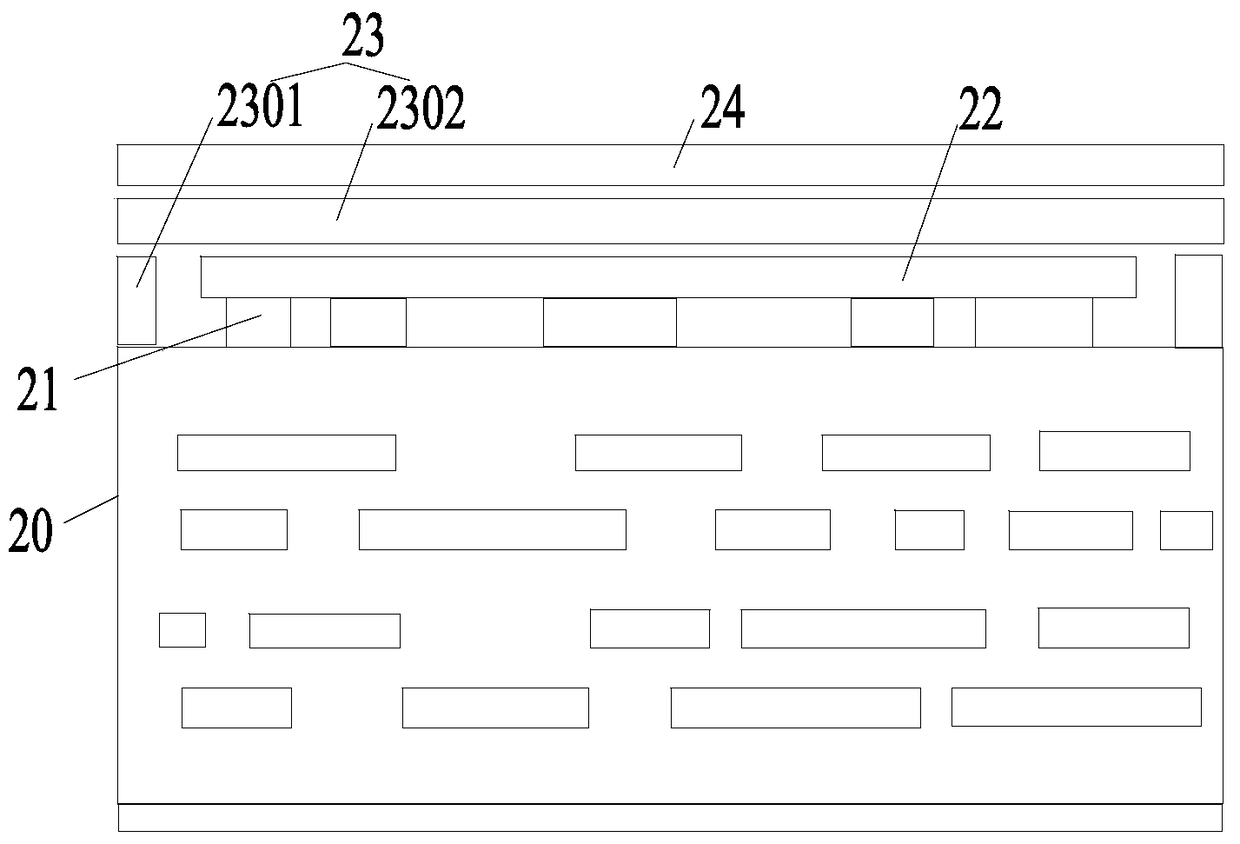

[0054] Please refer to image 3 , an embodiment of the present invention provides a circuit board with a single-sided annular ring.

[0055] The two sides of the circuit board have a first outer circuit layer 21 and a second outer circuit layer 26 respectively, and at least one metallized through hole 25 passes through the circuit board, wherein the metallized through hole 25 passes through the circuit board. The non-circuit pattern area of the first outer circuit layer 21, the second outer circuit layer 26 includes an annular ring 27 formed around the opening of the metallized through hole 25.

[0056] In some embodiments of the present invention, the circuit board includes at least one inner circuit layer, and the metallized through hole 25 is connected to one or more layers of the at least one inner circuit layer.

[0057] To sum up, the embodiment of the present invention discloses a circuit board with a single-sided annular ring. The circuit board to be processed can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com