Raymond mill scraper knife seat and manufacture method thereof

A Raymond mill and blade holder technology, applied in metal processing equipment, grain processing, etc., can solve problems such as easy direct fracture and blade holder damage, and achieve the effects of easy quality control, convenient processing and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

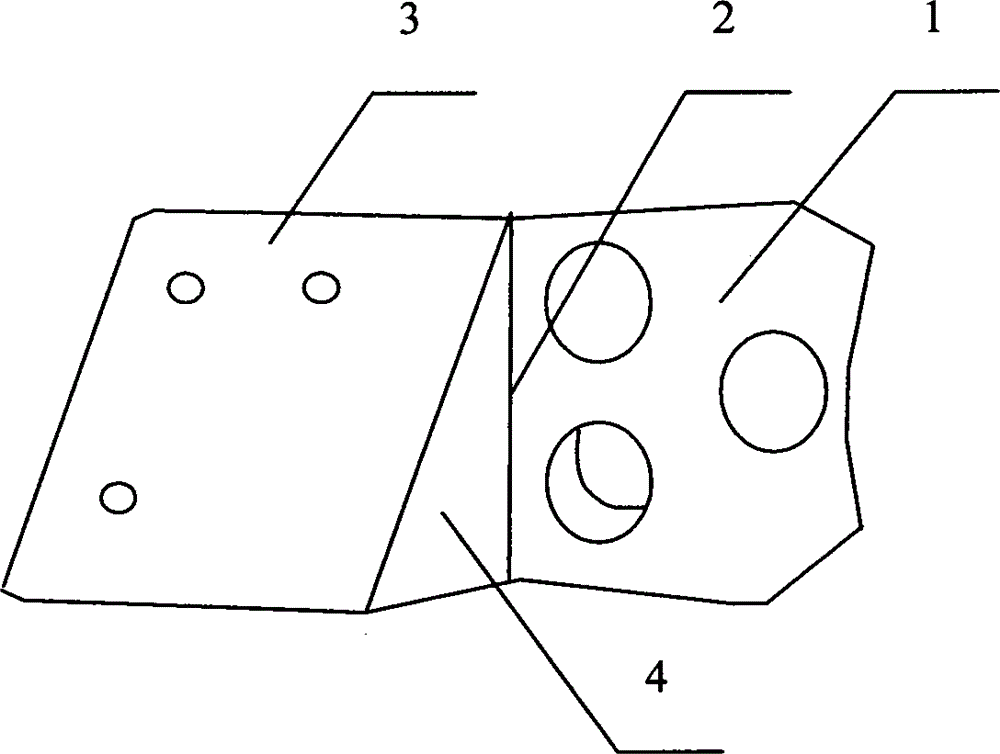

[0024] Such as figure 1 As shown, the shovel seat of a Raymond mill of the present invention is a whole, the main seat end 1 is installed on the shovel barrel, and the auxiliary seat end 3 is used to install the shovel. There is a folded plate 4 between the main seat end 1 and the auxiliary seat end 3 , and there is a knuckle line 2 between the folded plate 4 and the main seat end 1 .

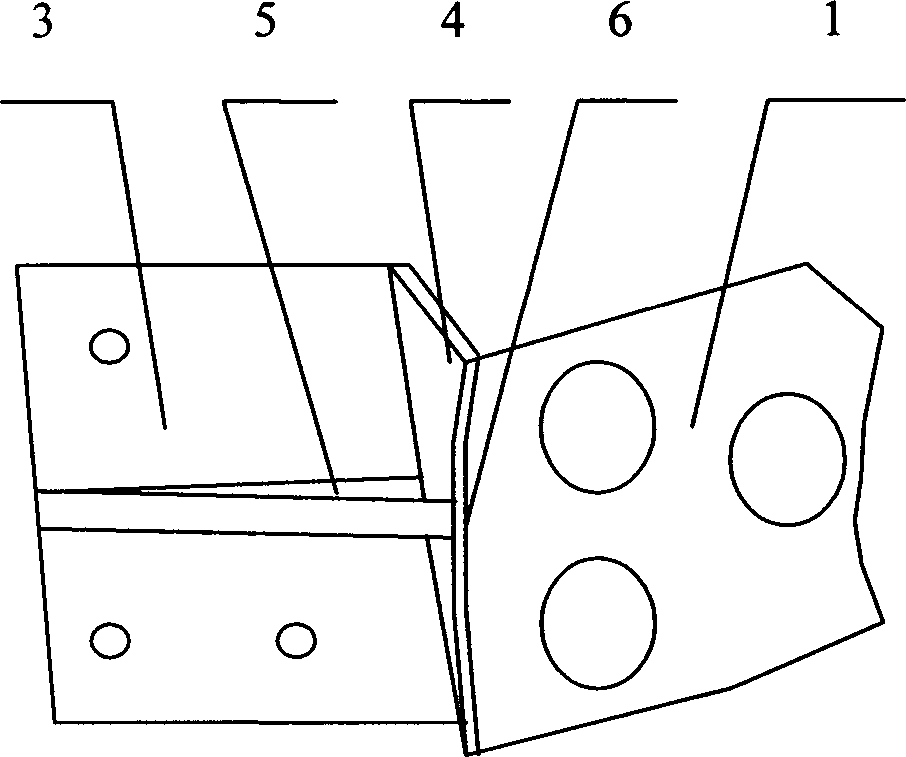

[0025] Such as figure 2 , on the back side, a reinforcing plate 5 is set between the auxiliary seat end 3 and the folded plate 4, and a positioning strip 6 is set at the bend between the main seat end 1 and the folded plate 4.

[0026] Its preparation method includes:

[0027] 1) Cutting: Obtain an A3 steel plate with a size that meets the requirements;

[0028] 2) Calcined at 850-1000°C;

[0029] 3) Forging and forming;

[0030] 4) natural cooling, drilling;

[0031] 5) Weld the reinforcement plate 5 between the auxiliary seat end 3 and the folded plate 4 on the back;

[0032] 6) Weld ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com