Powerful casting liquid adding system for aluminum alloy wheels

A technology for aluminum alloys and wheels, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient gates, difficulty in realizing automation, and high labor intensity of workers, so as to achieve no floor space occupation and useless power consumption small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

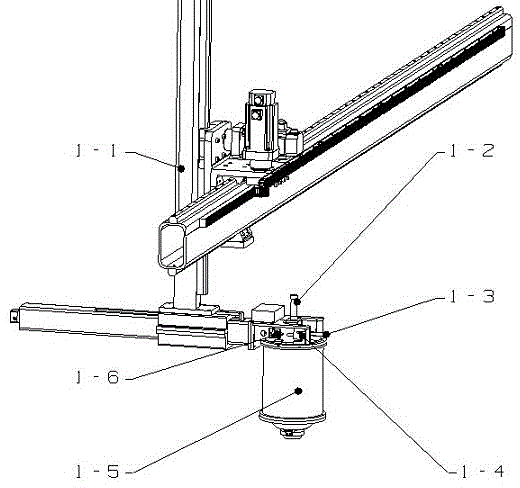

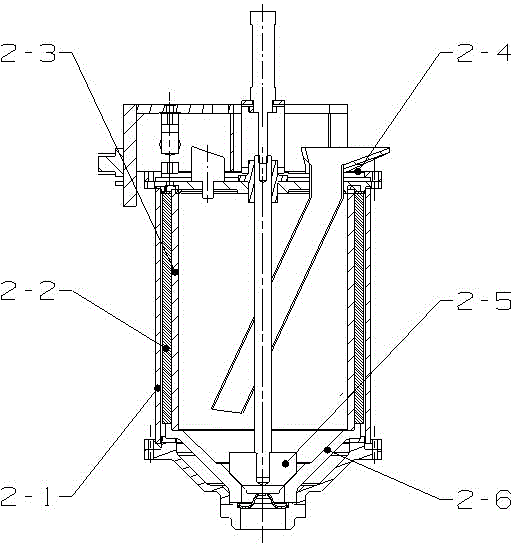

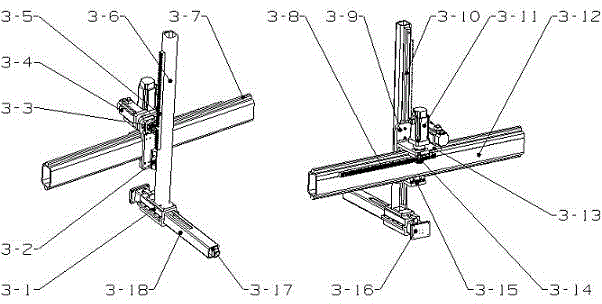

[0022] combined with figure 1 , attached figure 2 , attached image 3 and attached Figure 4 The structure and working process of the liquid-adding equipment for aluminum alloy wheel hub casting in the present invention will be described in detail.

[0023] The weight measuring device of the liquid adding equipment of the present invention is to measure the weight of the material liquid through the tension sensor (1-4) installed between the arm of the material feeding robot (1-1) and the upper cover of the material cylinder (2-4). Stop adding liquid after reaching the preset weight, realizing quantitative liquid addition.

[0024]The robot of the present invention is overhead and has three degrees of freedom. The horizontal mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com