Preparation method of cellulose triacetate ester film

A technology of cellulose triacetate and ester film, applied in flat products, applications, coatings, etc., can solve the problems of apparent quality influence, crystal point defects, affecting optical properties, etc., to improve uniformity and solve crystal point problems , the effect of improving the appearance and optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

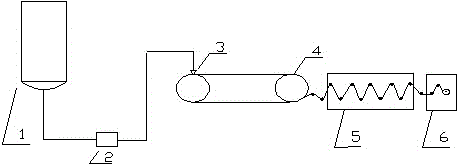

[0037] The preparation method of cellulose triacetate film of the present invention is:

[0038] 1. Drying treatment of cellulose triacetate

[0039] The raw material cellulose triacetate with a moisture content of 1%-3% is heated and dried at a wind temperature of 50-130°C, and the moisture content of the treated cellulose triacetate is ≤0.3% by weight.

[0040] 2. Methanol rewetting of cellulose triacetate

[0041] The cellulose triacetate treated in step 1 enters the methanol vapor, and the cellulose triacetate treated in step 1 is rehumidified in the methanol vapor, so that the methanol content of the treated cellulose triacetate reaches 0.1 -2% by weight.

[0042] 3. Preparation of cellulose triacetate cotton glue solution

[0043] The preparation process of the cellulose triacetate cotton glue of the present invention is the same as that of the existing cellulose triacetate cotton glue, including four steps of feeding, mixing and dissolving, filtering and standing at ...

Embodiment 1

[0062] 1. Drying treatment of cellulose triacetate

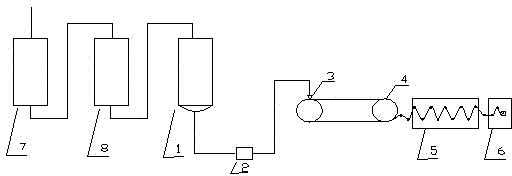

[0063] The cellulose triacetate with a moisture content of 2.0% is dried in the drying device 7 .

[0064] Air temperature 50 ℃ in drying device 7.

[0065] The water content of the treated cellulose triacetate was 0.3% by weight.

[0066] 2. Methanol rewetting of cellulose triacetate

[0067] The cellulose triacetate treated in step 1 is rehumidified in the cellulose triacetate methanol rehumidification device 8, so that the methanol content of the treated cellulose triacetate is 2% (by weight).

[0068] 3. Dissolution of cellulose triacetate

[0069] Add the cellulose triacetate treated in step 2 into the dissolving device 1 containing the main solvent, co-solvent and plasticizer for 5 hours to fully dissolve to prepare a uniform cotton glue solution. Test the dissolution quality of the cotton glue solution.

[0070] 4. Tape casting of cellulose triacetate film

[0071] After the cotton glue liquid obtained in proces...

Embodiment 2

[0073] 1. Drying treatment of cellulose triacetate

[0074] The cellulose triacetate with a moisture content of 2.0% is dried in the drying device 7 .

[0075] Air temperature in drying device 7 is 130°C.

[0076] The moisture content of the treated cellulose triacetate was 0.

[0077] 2. Methanol rewetting of cellulose triacetate

[0078] The cellulose triacetate treated in step 1 is rehumidified in the cellulose triacetate methanol rehumidification device 8, so that the methanol content of the treated cellulose triacetate is 1% by weight.

[0079] 3. Dissolution of cellulose triacetate

[0080] Add the cellulose triacetate treated in step 2 into the dissolving device 1 containing the main solvent, co-solvent and plasticizer for 5 hours to fully dissolve to prepare a uniform cotton glue solution. Test the dissolution quality of the cotton glue solution.

[0081] 4. Tape casting of cellulose triacetate film

[0082] After the cotton glue liquid obtained in process 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com