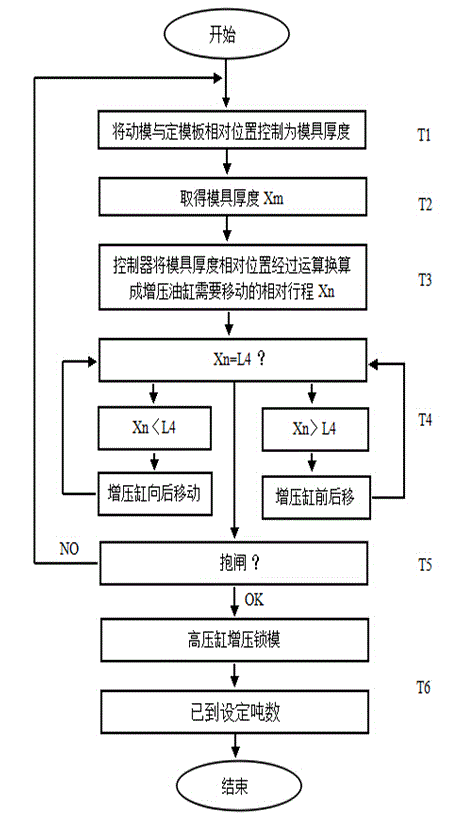

Mould adjusting method used for two plate type mould clamping device

A two-plate, clamping technology, which is applied in the field of mold adjustment of two-plate injection molding machines and two-plate clamping devices, can solve the problems of low automation, rough adjustment, failure of closing and closing, etc., achieves a high degree of intelligence, and eliminates measurement Mechanical error, fast clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

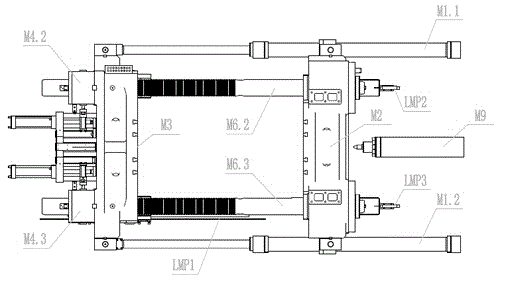

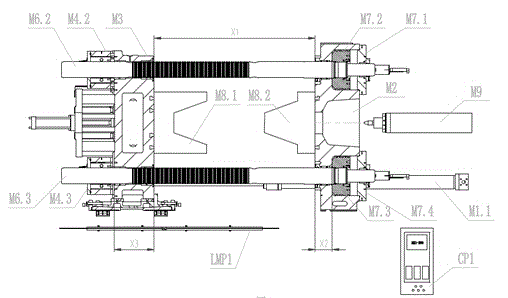

[0018] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings. In addition, the drawings of the present invention do not limit the present invention, but are used to make the present invention easier to understand. In addition, in order to avoid ambiguity of the present invention, detailed descriptions of peripheral parts are omitted.

[0019] see Figure 2~Figure 5 , the present invention includes M1.1, M1.2: movable mold cylinder and connecting rod, M2: fixed template, M3: movable template, M4.1, M4.2, M4.3, M4.4: brake mechanism, M5 .1, M5.2, M5.3, M5.4: booster cylinder, M6.1, M6.2, M6.3, M6.4: Corinthian column, M7.1, M7.2, M7.3 , M7.4: booster cylinder piston, M8.1, M8.2: mold, M9: injection mechanism, LMP1: mold thickness digital position sensor, LMP2, LMP3, LMP4, LMP5: booster cylinder position sensor, S1, S2, S3, S4: Brake closing confirmation sensor, CP1: Controller, X1: Mold thickness, X2: The thickness from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com