Sludge powder mixing machine

A sludge powder and powder mixing knife technology, which is applied in mixers, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as failure to meet process requirements, high sand content, and difficulty in replacement, and reduce The effect of easy external damage rate, overcoming severe impact and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

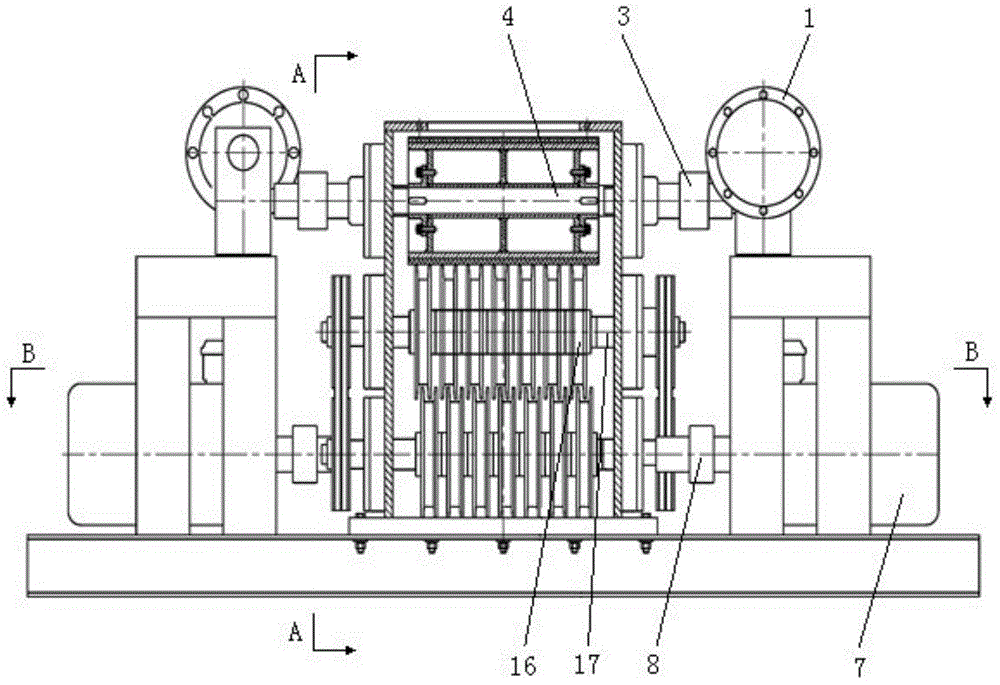

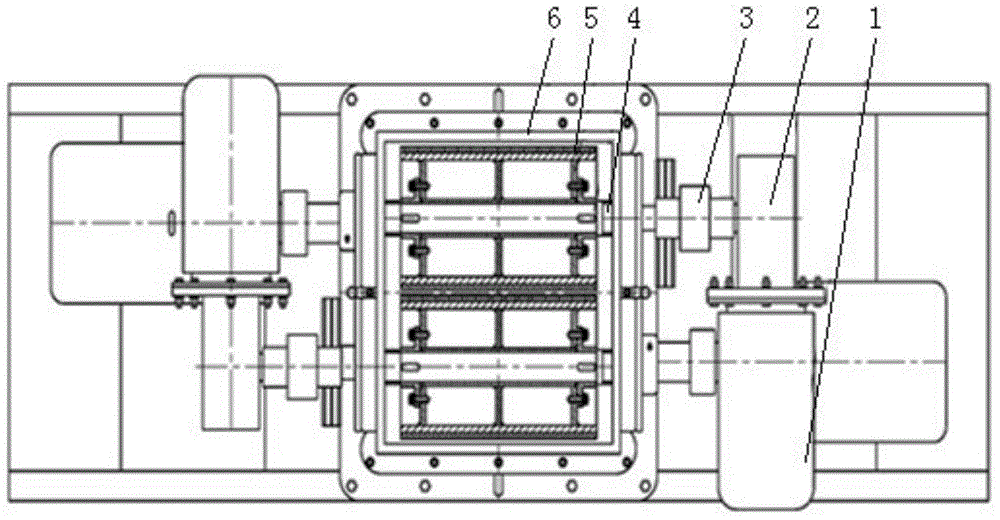

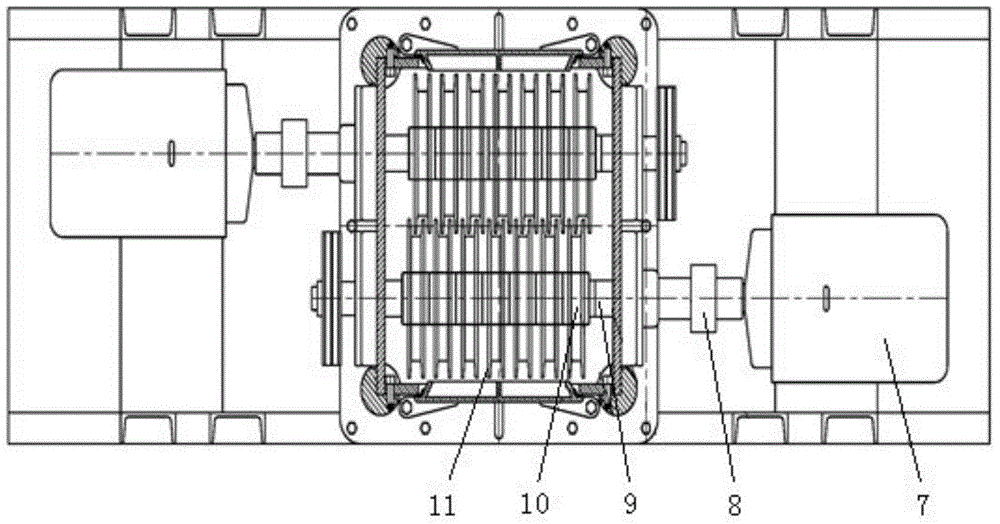

[0027] With reference to the drawings, the present invention is realized as a sludge powder mixer, which includes a motor A1, a worm gear reducer 2, a coupling C3, a drum shaft 4, a drum 5, a chassis 6, a motor B7, and a coupling D8, the driving rotor shaft 9, the driving rotor 10, the powder mixing knife 11, the pulley 12, the belt 13, the frame 14, the driven rotor 16, and the driven rotor shaft 17; For the parallel drum shaft 4, a pair of parallel driven rotor shafts 17 and a pair of parallel driving rotor shafts 9, the upper and lower adjacent driven rotor shafts 17 and the driving rotor shaft 9 are driven by a belt 13; the drum 5 is set on the drum shaft 4. One end of the drum shaft 4 is connected to the motor A1 via the coupling C3 and the worm gear reducer 2 in sequence. The motor A1 is arranged on the frame 14 and drives the two drums 5 to rotate in opposite directions And the upper ends of the two rollers both move towards between the two rollers; the active rotor 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com