PA6 type polyamide thermoplastic elastomer preparation method

A thermoplastic elastomer and polyamide technology, which is applied in the field of preparation of PA6 type polyamide thermoplastic elastomer, can solve the problems of high purity requirements of reaction raw materials, low polymer molecular weight, general product performance, etc., and achieves easy control and easy reaction. , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

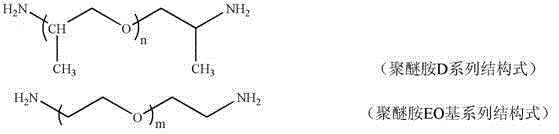

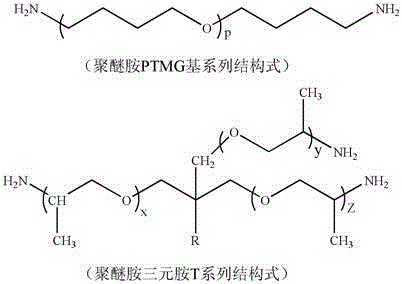

Method used

Image

Examples

Embodiment 1

[0018] Add 1000g caprolactam, 117g polyetheramine D2000, 53g water in the polymerization kettle, 2 Under protection, 230℃, vacuum degree 4000pa, reaction for 16h. After boiling water extraction and vacuum drying, PA6 thermoplastic elastomer is obtained. The tensile strength is 47Mpa, the elongation at break is 260%, and the Shore hardness is 65D.

[0019]

Embodiment 2

[0021] Add 1000g caprolactam, 117g polyetheramine D2000, 53g water in the polymerization kettle, 2 Under protection, 250℃, vacuum degree 4000pa, reaction for 12h, vacuum 4h, boiling water extraction, vacuum drying, then PA6 thermoplastic elastomer can be obtained. The tensile strength is 52Mpa, the elongation at break is 360%, and the Shore hardness is 70D.

[0022]

Embodiment 3

[0024] Add 1000g caprolactam, 461.5 polyetheramine D2000, 76.9g water into the polymerization kettle, 2 Under protection, 230℃, vacuum degree 4000pa, reaction for 16h. After boiling water extraction and vacuum drying, PA6 thermoplastic elastomer is obtained. The tensile strength is 27Mpa, the elongation at break is 560%, and the Shore hardness is 35D.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com