Method for producing n-alkane solvent oil from Fischer-Tropsch synthetic oil

A technology for Fischer-Tropsch synthetic oil and n-alkane, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problem of inability to obtain n-alkane solvent oil, etc., and achieves various models, simple process flow and high quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

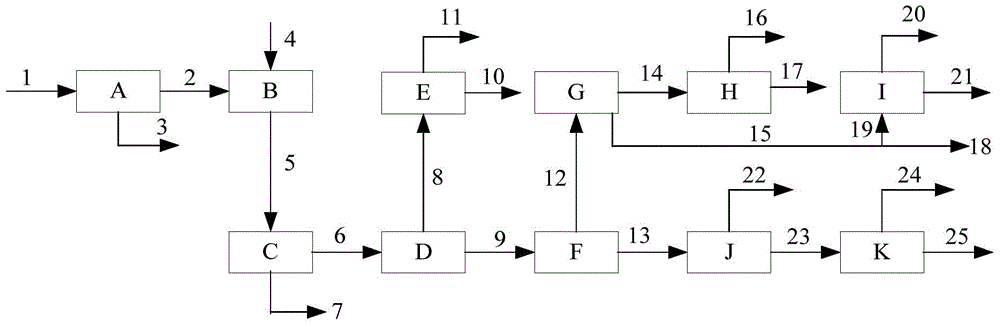

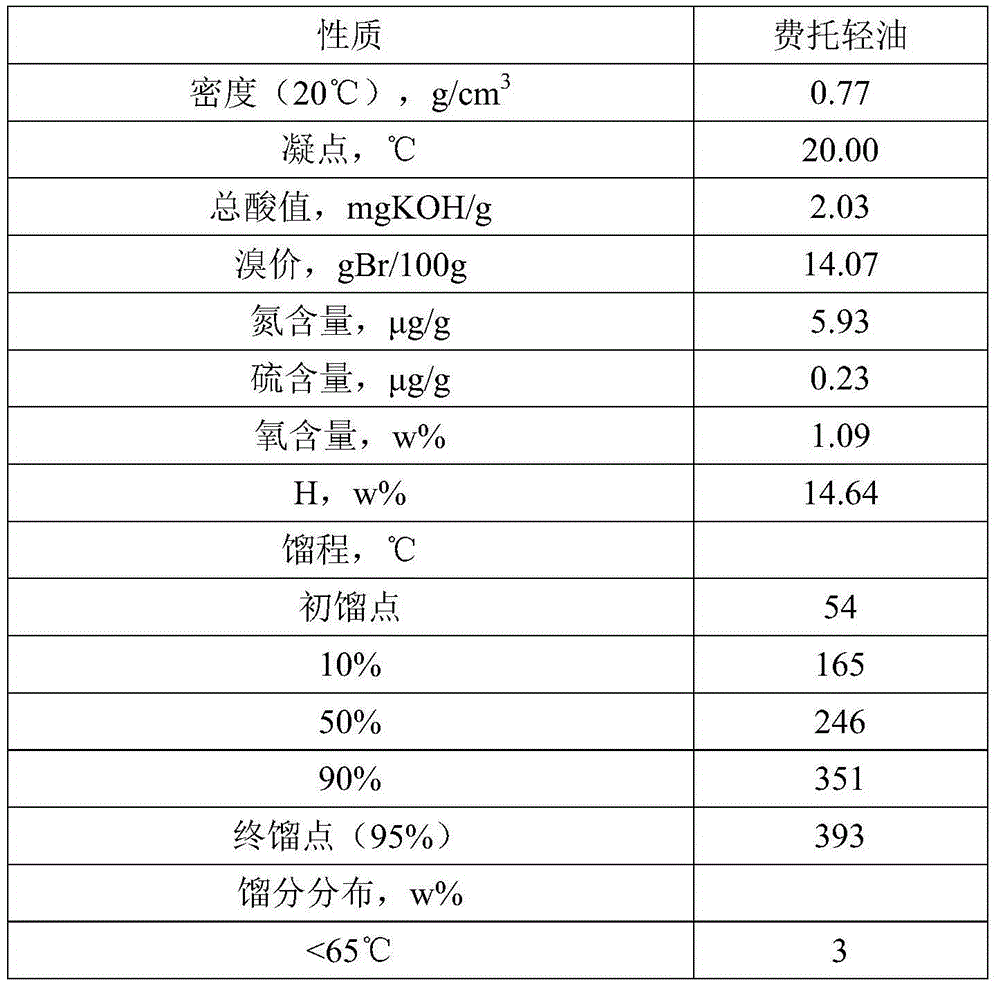

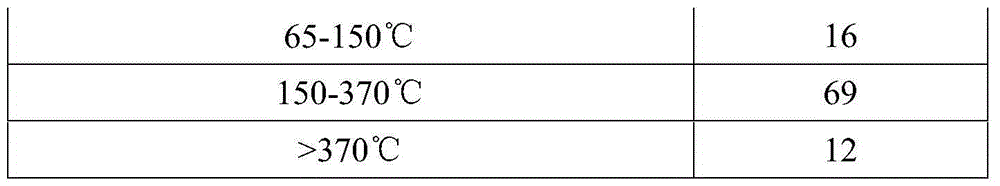

[0054] Fischer-Tropsch synthetic light oil stream 1, its properties are shown in Table 1, enters technical process according to the method of the present invention, the implementation condition of each step is:

[0055] Fractionation column A has a theoretical plate number of 40, a reflux ratio of 3, a feeding position of the 20th plate from the top, a tower top temperature of 110°C, and a tower bottom temperature of 268°C;

[0056] Hydrofining unit B uses Ni-W / Al 2 o 3 Catalyst, the reaction temperature is 350°C, the pressure is 6.5MPa, the volume space velocity is 1, and the light oil ratio is 800;

[0057] The theoretical plate number of the degassing tower C is 30, the feeding position is the 15th plate from the top, the reflux ratio is 3, under normal pressure, the temperature at the top of the tower is -4.1°C, and the temperature at the bottom of the tower is 113.1°C;

[0058] C 6 / C 7 The theoretical plate number of the cutting tower D is 30, the feeding position is...

Embodiment 2

[0068] Fischer-Tropsch synthetic light oil stream 1, its properties are shown in Table 1, enters the technical process described in this method, and the implementation conditions of each step are:

[0069] Fractionation column A has a theoretical plate number of 20, a reflux ratio of 6, a feeding position of the 10th plate from the top, a tower top temperature of 112°C, and a tower bottom temperature of 267°C;

[0070] Hydrofining unit B uses Ni-W / Al 2 o 3 Catalyst, the reaction temperature is 330°C, the pressure is 3MPa, the volume space velocity is 1, and the light oil ratio is 600;

[0071] The theoretical plate number of the degassing tower C is 20, the feeding position is the 10th plate from the top, the reflux ratio is 5, under normal pressure, the temperature at the top of the tower is -4.1°C, and the temperature at the bottom of the tower is 113.1°C;

[0072] C 6 / C 7 The theoretical plate number of the cutting tower D is 20, the feeding position is the 10th plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com