Gas recovery method for horizontal butt joint wells with hydraulic scouring, migration, pressure relief and outburst elimination

A technology for docking wells and horizontal wells, applied in the field of gas outburst elimination and coalbed methane extraction, can solve problems such as failure to achieve expected results, and achieve the effects of shortening construction period, increasing extraction efficiency, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

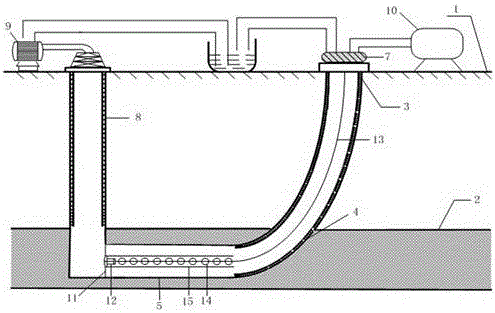

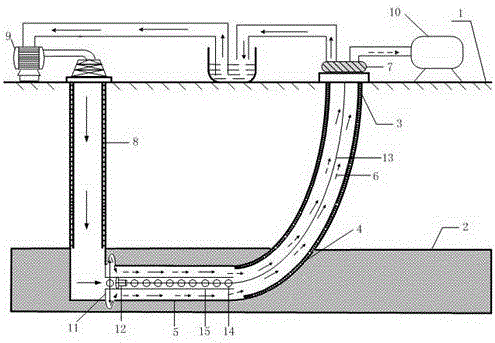

[0022] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

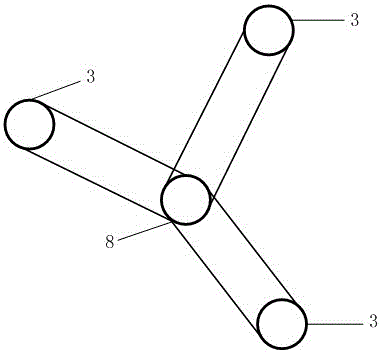

[0023] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the specific implementation steps of the horizontal docking well hydraulic scouring migration, pressure relief and outburst gas recovery method of the present invention are as follows:

[0024] (1) A vertical well 8 is drilled at a predetermined position. The well is drilled from the surface 1 to the bottom plate of the target coal seam 2. The well is completed with casing above the roof of the coal seam and completed with open hole below the roof of the coal seam.

[0025] (2) The horizontal well 3 is connected with the vertical well 8, the vertical well 8 and the deflection section 4 are casing-fixed, and the screen pipe 15 is lowered in the horizontal section 5 to ensure the smooth connection of the joint section and prevent clogging. The screen hole 14 should be large to reduce fluid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com