Vertical axis wind turbine with protecting device capable of adjusting wind wheel radius

A protection device and vertical axis technology, applied in the direction of wind turbines, wind turbines, and wind motor combinations at right angles to the wind direction, can solve problems such as lack of wind turbines, increase the rotational inertia of wind turbines, and reduce wind turbine efficiency, so as to prevent wind turbine accidents and improve The effect of improving the working range and aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

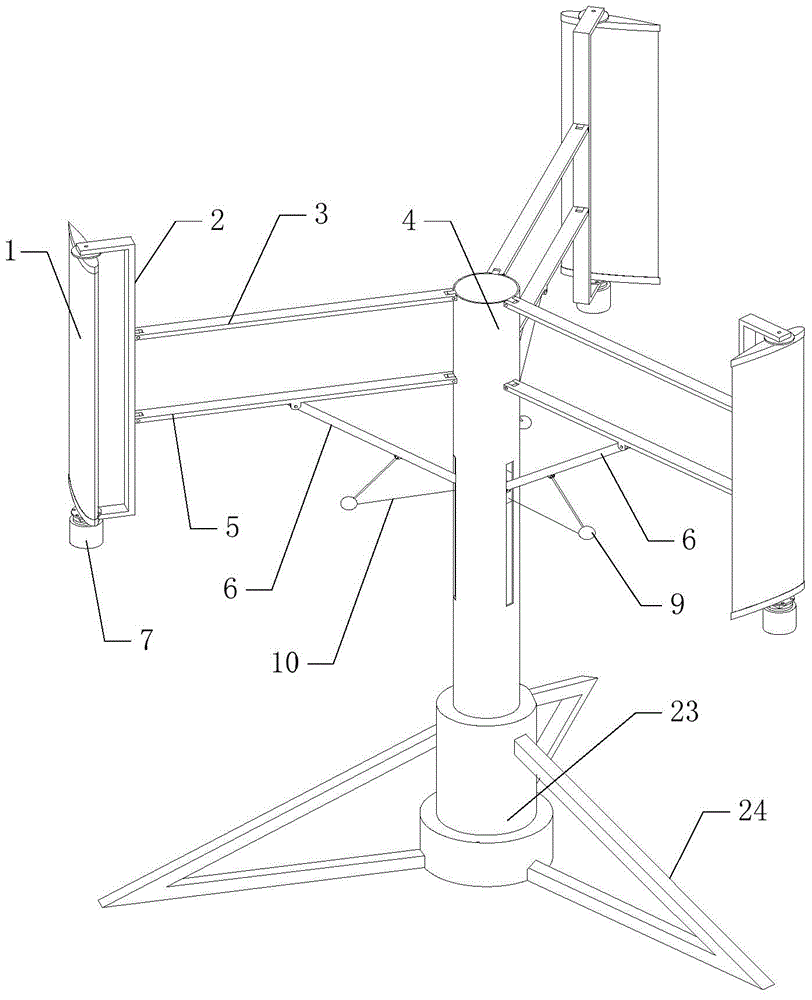

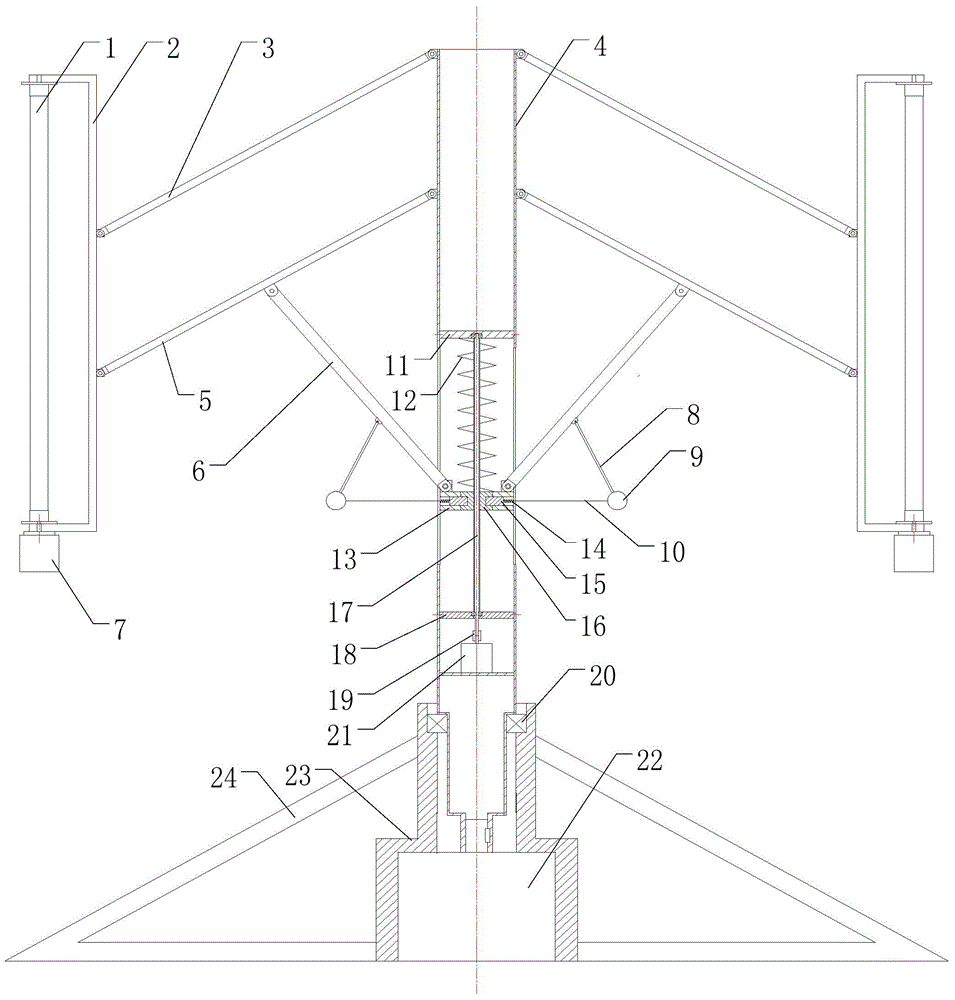

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

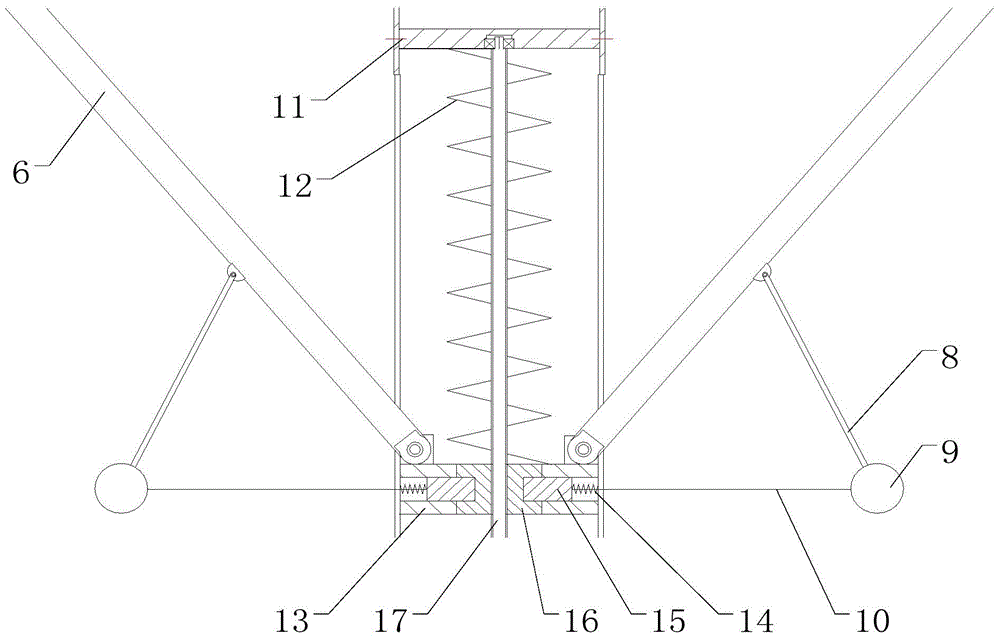

[0016] combine Figure 1~4 , the generator 22 is installed at the bottom of the tower 23, the tower 23 is fixed to the ground through the reinforcement rib 24; the output shaft of the main shaft 4 and the generator 22 is linked by a key, and the outer ring of the main shaft 4 is connected to the tower 23 through the bearing 20 The inner ring fits; the blade 1 is installed in the blade bracket 2, the blade 1 is fixed with the output shaft of the pitch motor 7 and can rotate around the axis; Hinged; the lower part of the support rod 6 is hinged with the sliding plate 13; the screw nut 16 is installed on the screw rod 17, the screw rod 17 rotates to make the screw nut 16 move up and down, and the safety pin 15 drives the sliding plate 13 to move up and down, pushing the support rod 6 drives support 5 to draw in or expand.

[0017] combine figure 2 , 3, 4,, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com