Antistatic self-cleaning fan blade and process for manufacturing same

A manufacturing process and self-cleaning technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as poor antistatic self-cleaning performance, and achieve low cost, Less dust and less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

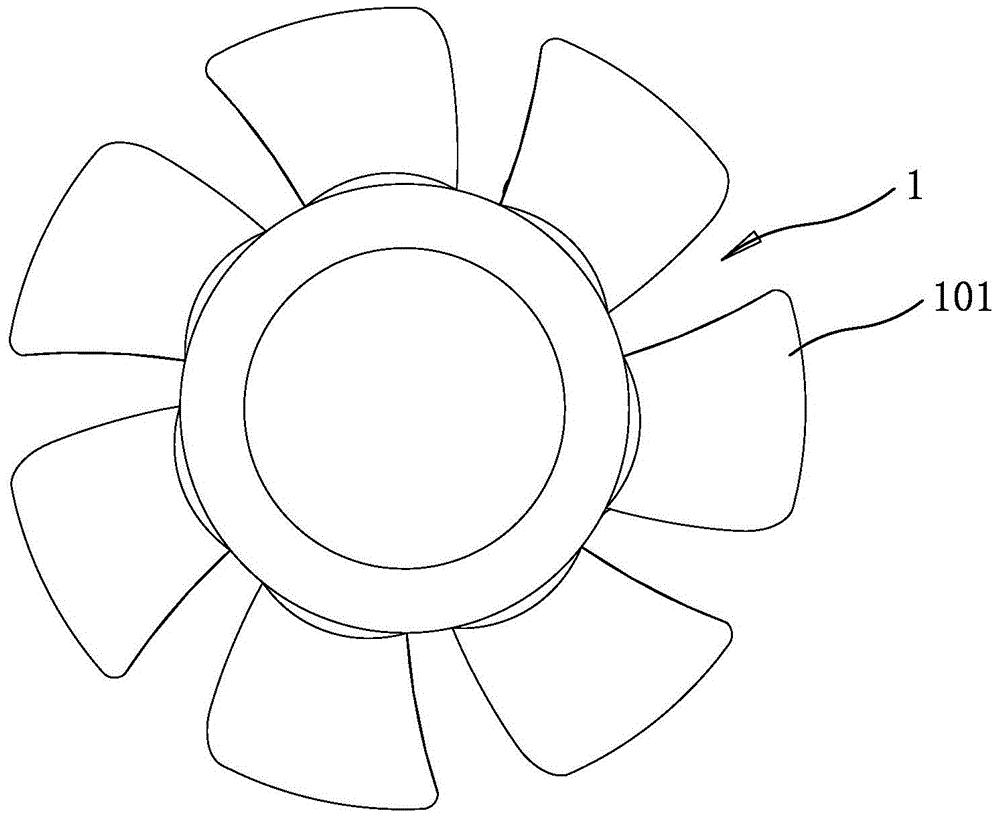

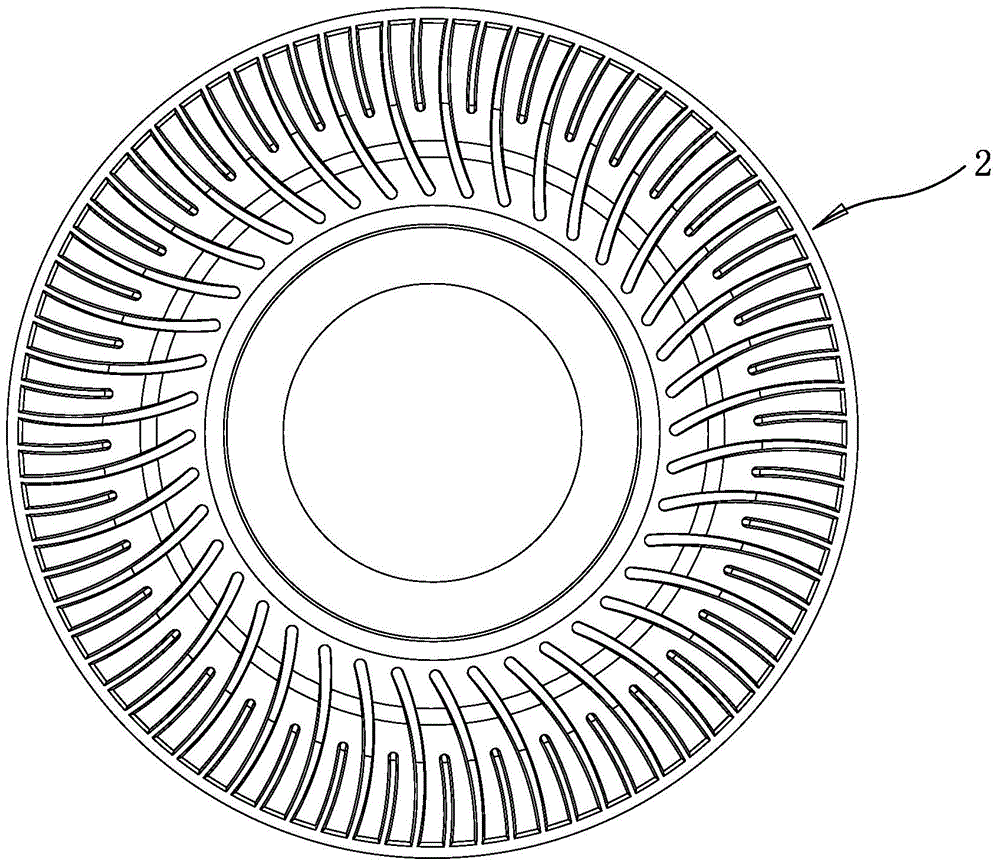

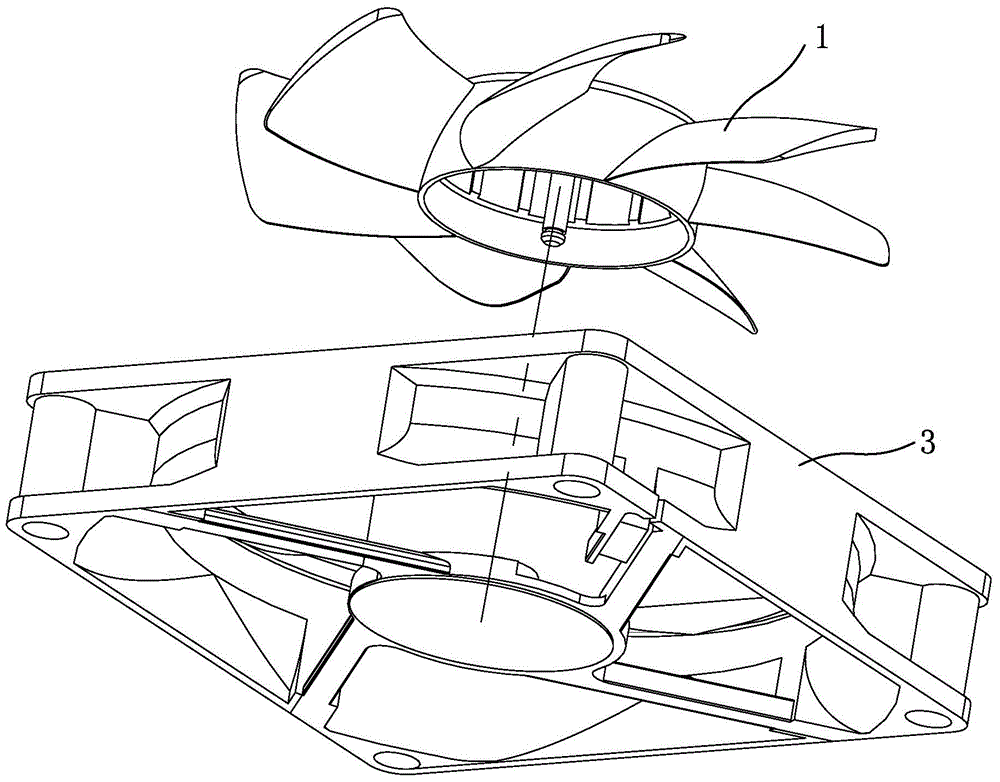

[0019] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as figure 1 , image 3 As shown, the cooling fan includes a set of rotating body, motor group and bearing. The cooling fan has the same composition as the traditional structure of the rotating body, motor group, base frame, bearings, etc. The rotating body includes a shaft core, plastic fan blades, magnetic strips, and a motor case. The fan body 1 is placed in the cooling fan frame 3. The fan body is provided with fan blades 101 . At the same time, if figure 2 As shown, the fan body can also adopt the net cover fan 2, that is, the net cover of the net cover fan is provided with swirl-shaped fan blades and hollow holes. In the present invention, a certain proportion of antistatic and self-cleaning materials are added to the engineering plastic particles of the plastic fan blade, and the traditional process of engineering plastic injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com