Waveform-variable automatic impact device for modal test

A modal test and impact device technology, applied in the measurement device, the use of a single impact force test material strength, impact test and other directions, can solve the problems of high degree of automation, uncontrollable waveform width, etc., to achieve high reliability and repeatability Strong, avoid the effect of combo phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

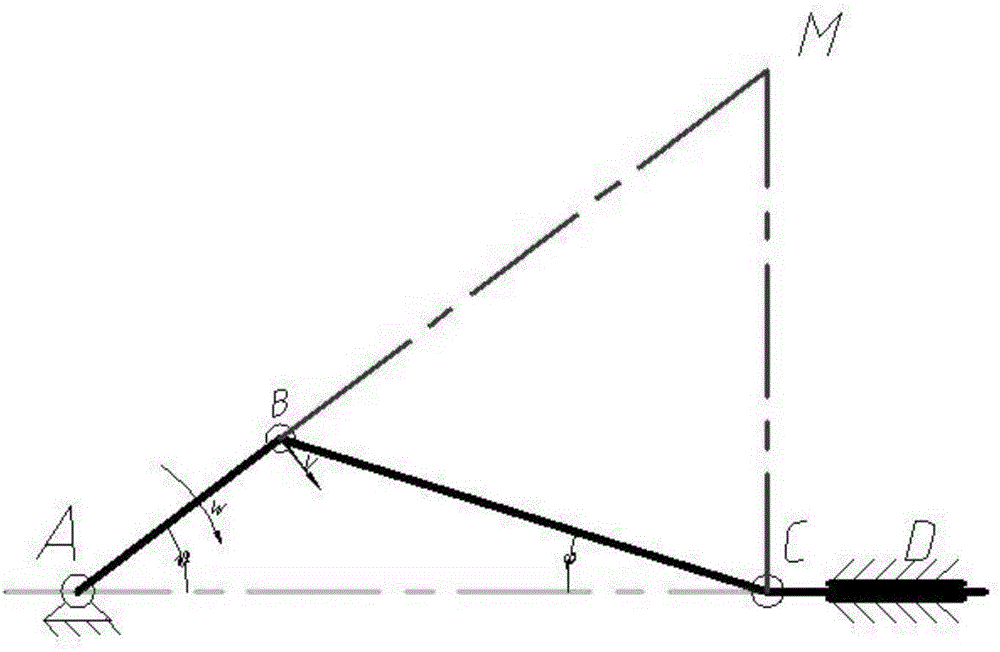

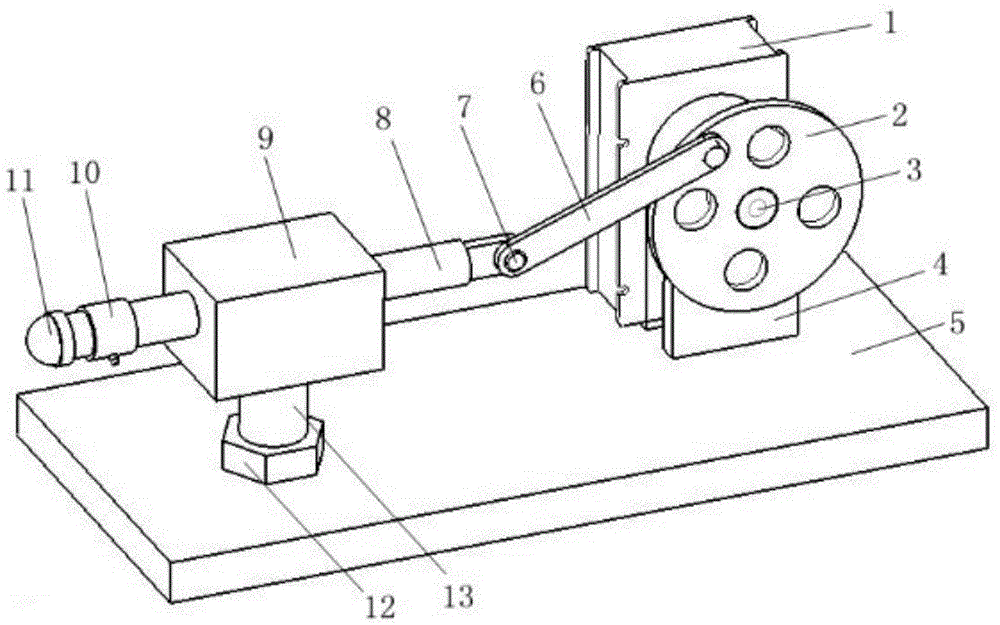

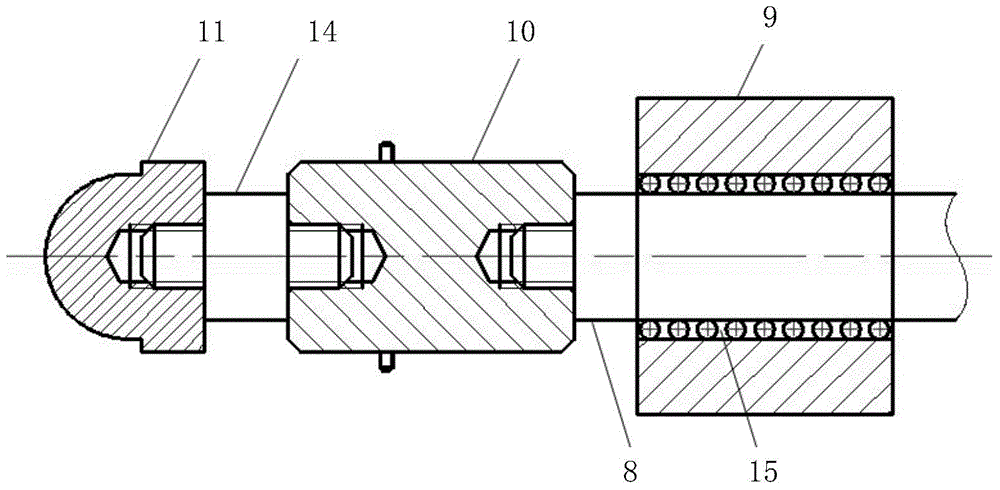

[0019] combine Figure 1 to Figure 4 , a new automatic impact device with a variable waveform for modal testing designed by the present invention consists of a workbench 5, a support plate 4, a fixed guide rail 9, an adjustment column 13, a connecting rod 6, a hammer body 8, a hammer cap 11, and a sensor 10. For the composition of smart steering gear 1, crank plate 2 and some connecting parts, see figure 2 .

[0020] The support plate 4 and the fixed guide rail 9 are fixed on the workbench 5. There is a circular through hole on the top of the support plate 4, and a ball bearing is embedded in the hole, which plays the role of supporting the shaft section and lubricating the rotating pair. The rotation output end of the steering gear fixed on the support plate is connected with the shaft. The crank disc 2 is fixed on the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com