A 6kv high voltage motor forming coil and its processing method

A technology of high-voltage motors and forming coils, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of occupying the high point of the motor mechanism and the limitation of the utilization rate of the motor slot, so as to reduce manufacturing costs, save social costs, reduce Effect of small weight-to-power ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

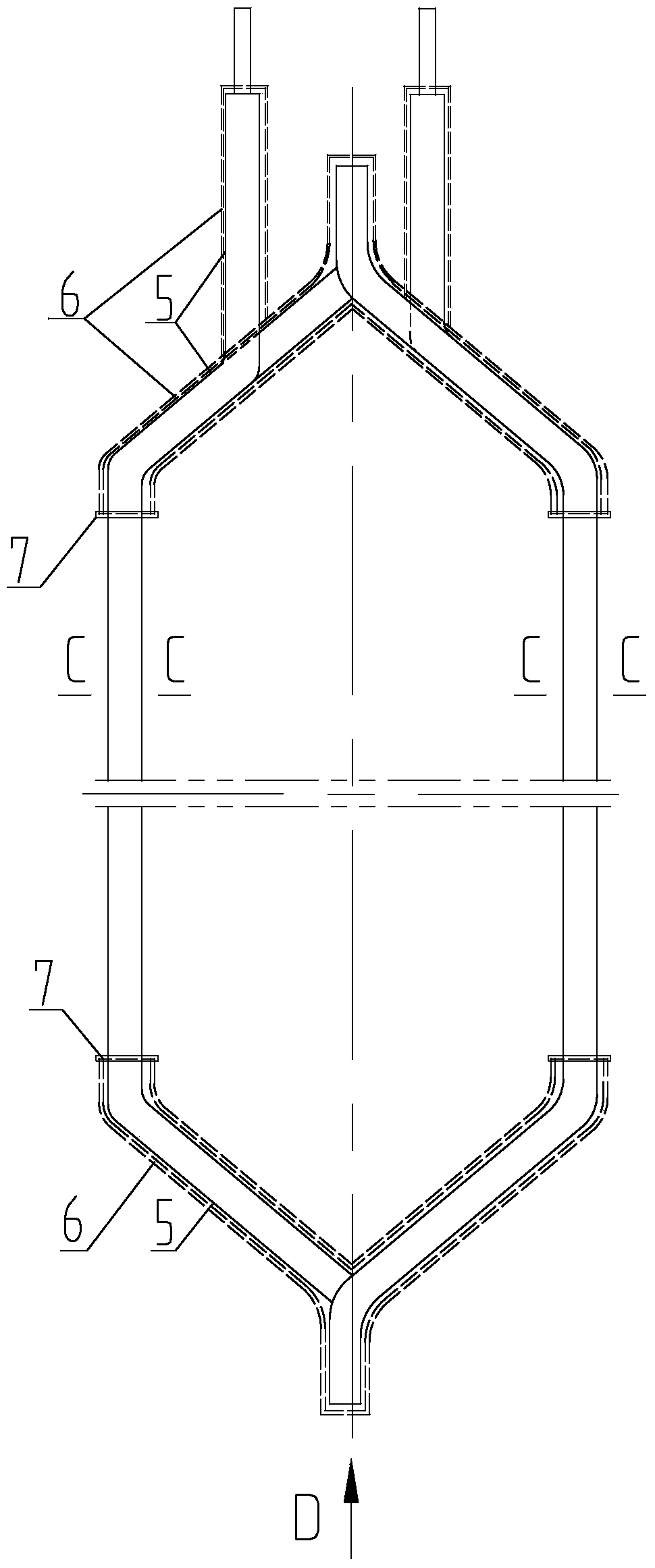

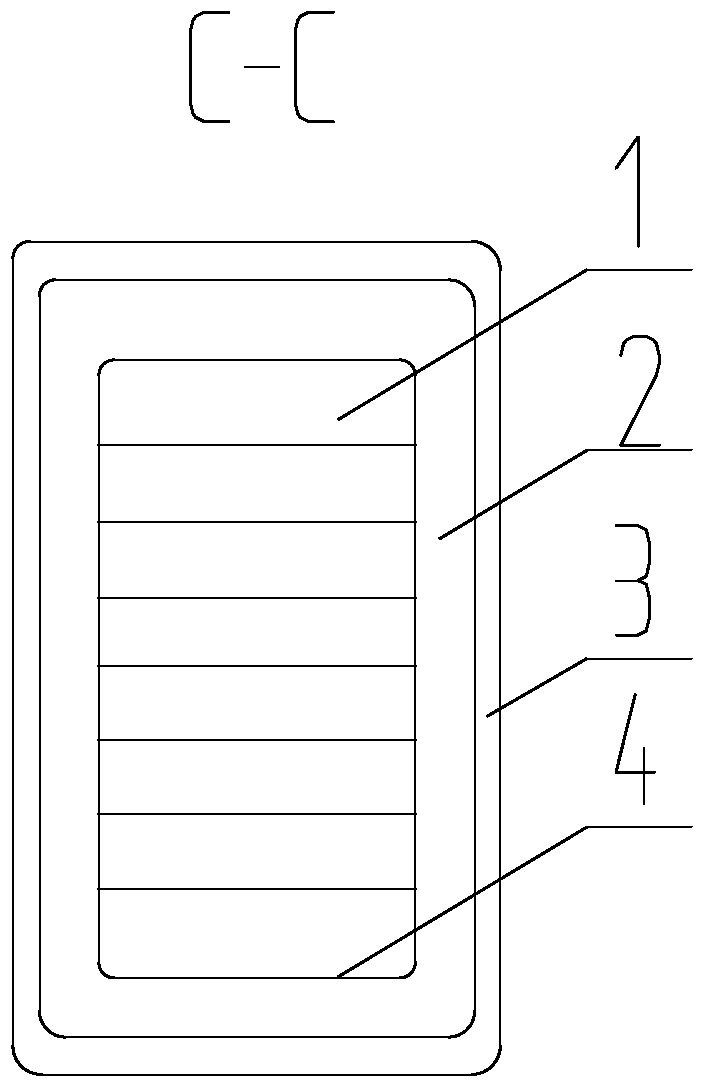

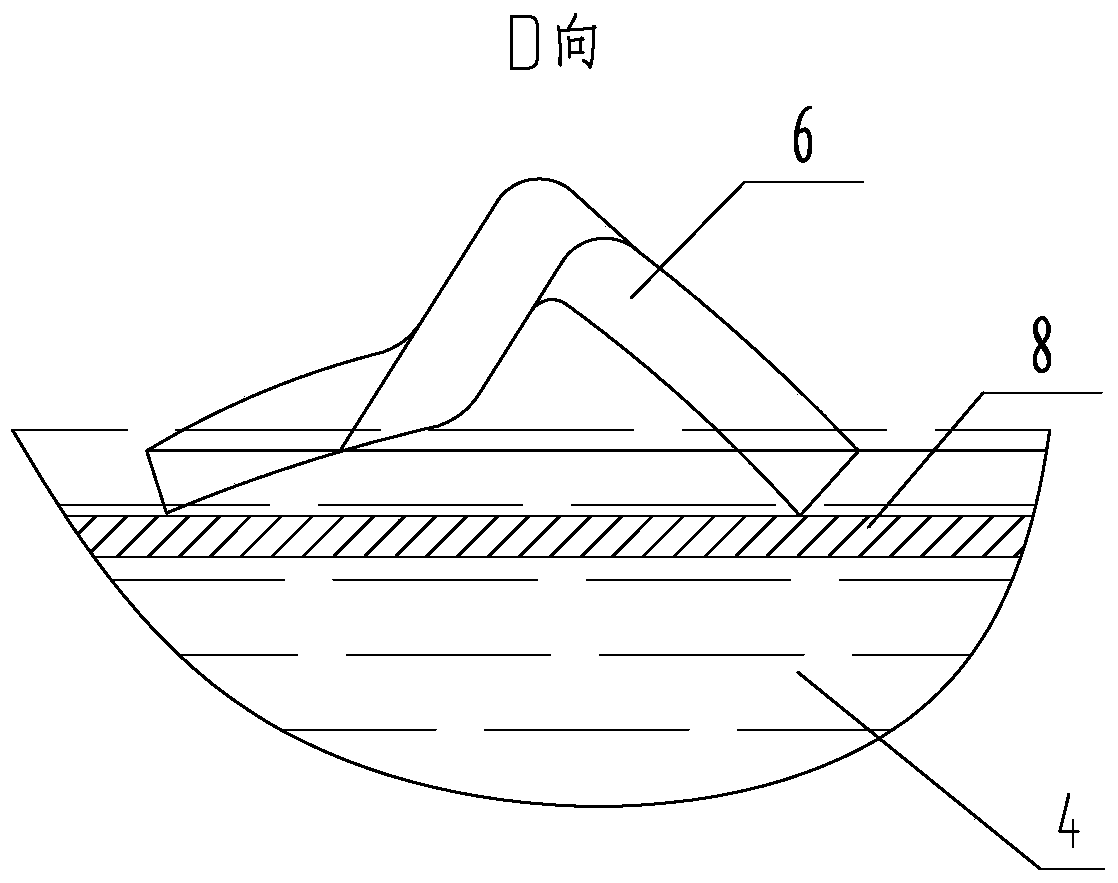

[0039] Such as figure 1 , 2 , as shown in 3,

[0040] In this technical plan, mica tape is selected to wrap copper flat wire 1 to wind the coil, and epoxy glass mica tape with less adhesive powder (5442-1) and epoxy polyester film with less adhesive powder mica tape (5442-1) with less adhesive composition 0.13mm thick and 25 mm wide (5442-1D) Four layers of mica insulation layer 2 are mixed and half-stacked outside the coil as the coil. The thickness of one side of the mica insulation is 1.04mm, and a layer of 0.08mm thick and 25mm wide is flat-wrapped outside the coil mica insulation layer 2. The anti-halation tape is used as the protective insulating layer 3, the main insulating layer of the coil is composed of the coil mica insulating layer 2 and the protective insulating layer 3, and the thickness of one side of the main insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com