110kV-level thyristor valve body

A technology of thyristor valve body and thyristor, which is applied in the direction of electrical components, pulse technology, electronic switches, etc., can solve the problem of inability to meet the voltage and current capacity requirements of UHV static var compensation equipment, poor heat dissipation effect of heat sink, and poor structural layout. Reasonable and other issues, to achieve the effect of improving heat dissipation capacity and service life, uniform water supply, and high frame structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

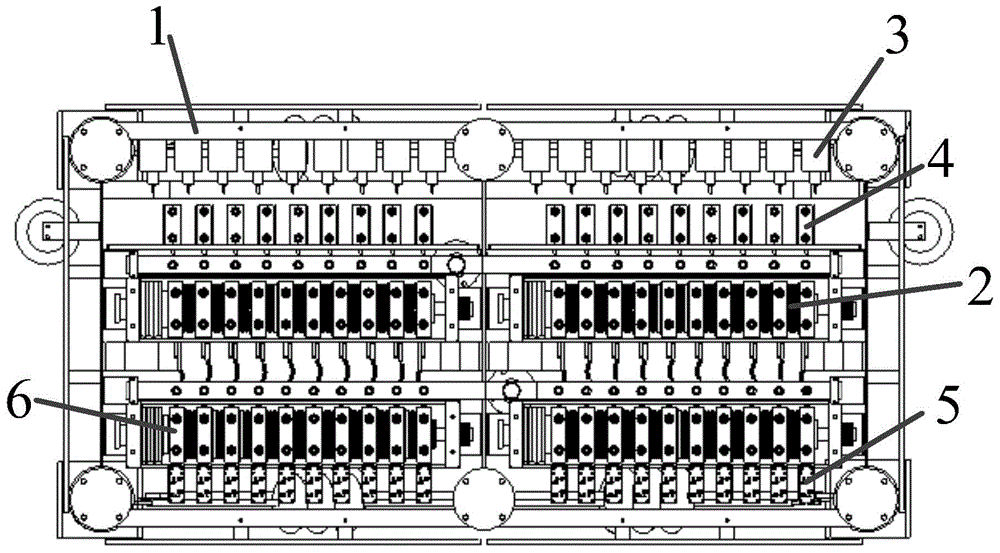

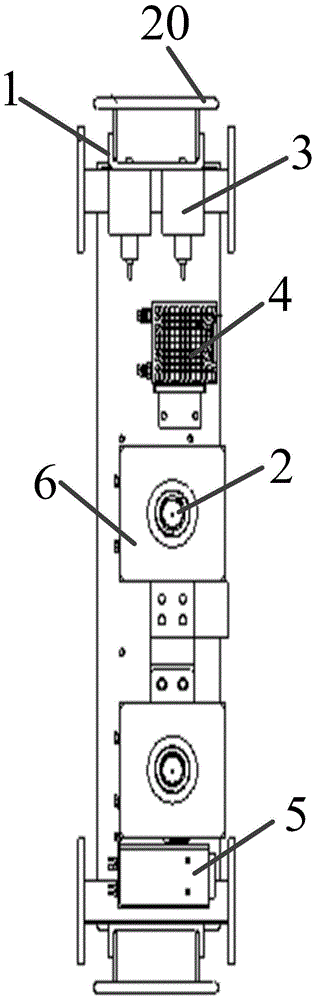

[0050] Such as figure 1 As shown, a 110kV grade thyristor valve body, the thyristor 2 is a switching device provided with semiconductor elements; the valve body is a rectangular frame 1 with a thyristor valve body module and a heat dissipation device inside; it is characterized in that,

[0051] Such as figure 2 As shown, the thyristor valve body module includes a absorption capacitor 3 arranged along the lateral direction of the frame 1, a water cooling resistor 4, a thyristor 2 and a trigger plate 5 connected to the heat sink;

[0052] The thyristor valve body modules are arranged in parallel along the longitudinal direction of the frame 1 .

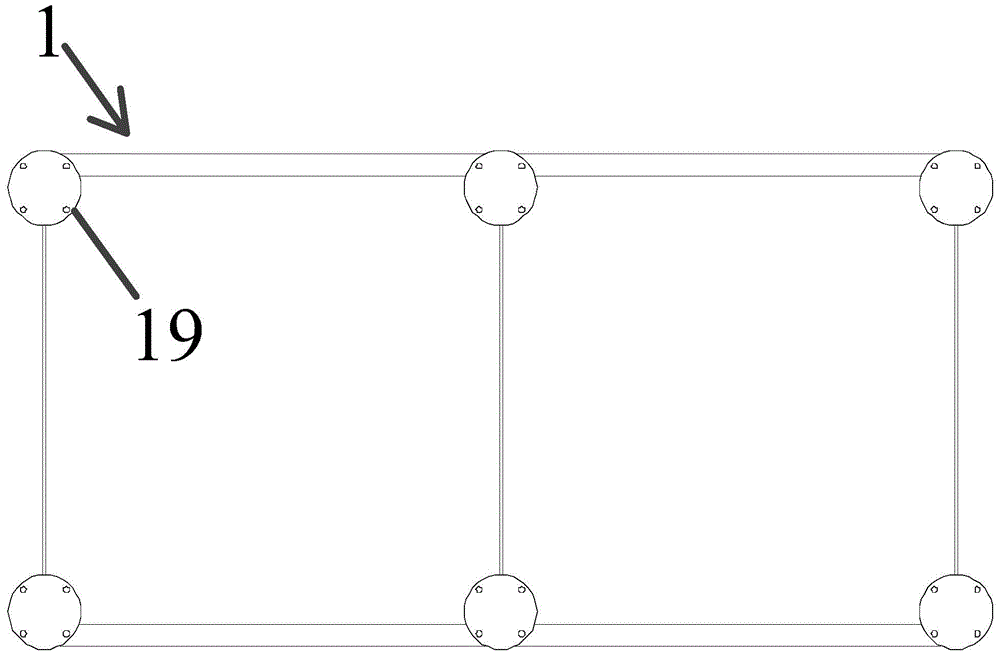

[0053] Such as image 3 As shown, the frame 1 is a sun-shaped frame composed of beams and vertical beams;

[0054] A connector for fixing the thyristor valve body module arranged in parallel along the longitudinal direction is provided in the zigzag frame;

[0055] A disc-shaped fixing member 19 parallel to the axial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com