Orifice burr removing method and apparatus

A burr and orifice technology, applied in the field of circuit board production, to improve processing efficiency and increase cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

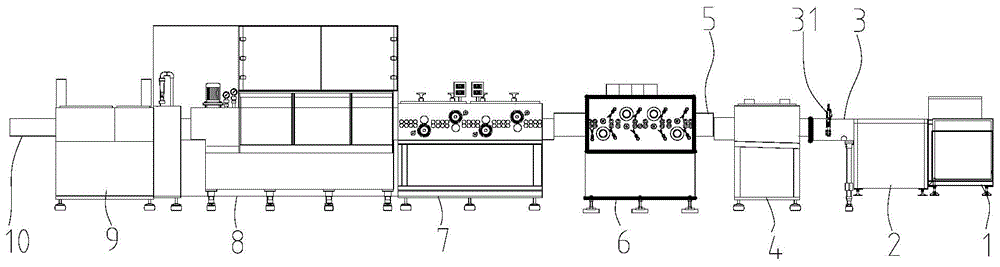

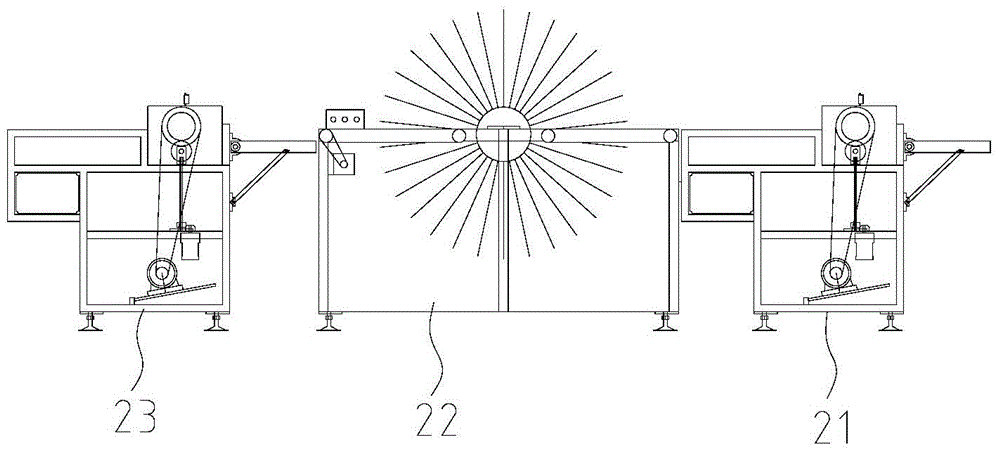

[0024] refer to Figure 1-2 , this embodiment provides a method for removing burrs from an orifice, and a device for removing burrs from an orifice using this method.

[0025] Firstly, according to the circuit board production process in the prior art, the base material is cut to obtain a base plate for preparing each inner layer board. After the conventional pretreatment of the substrate, the inner layer circuit pattern is made on the substrate through the steps of applying wet film on the substrate, exposing, developing, etching, and stripping the film (negative film process), thereby making each inner layer board. Inspect and evaluate the quality of each inner layer board through inner layer AOI.

[0026] Then, the inner layer board is browned by using the existing browning process of the inner layer board before lamination, so that a layer of brown oxide is formed on the inner layer board, and the surface of the inner layer board is roughened. Then, according to the desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com