Polymer thickened grease composition and method of making the same

A polymer and grease technology, applied in lubricating compositions, thickeners, petroleum industry, etc., can solve problems such as instability and achieve good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

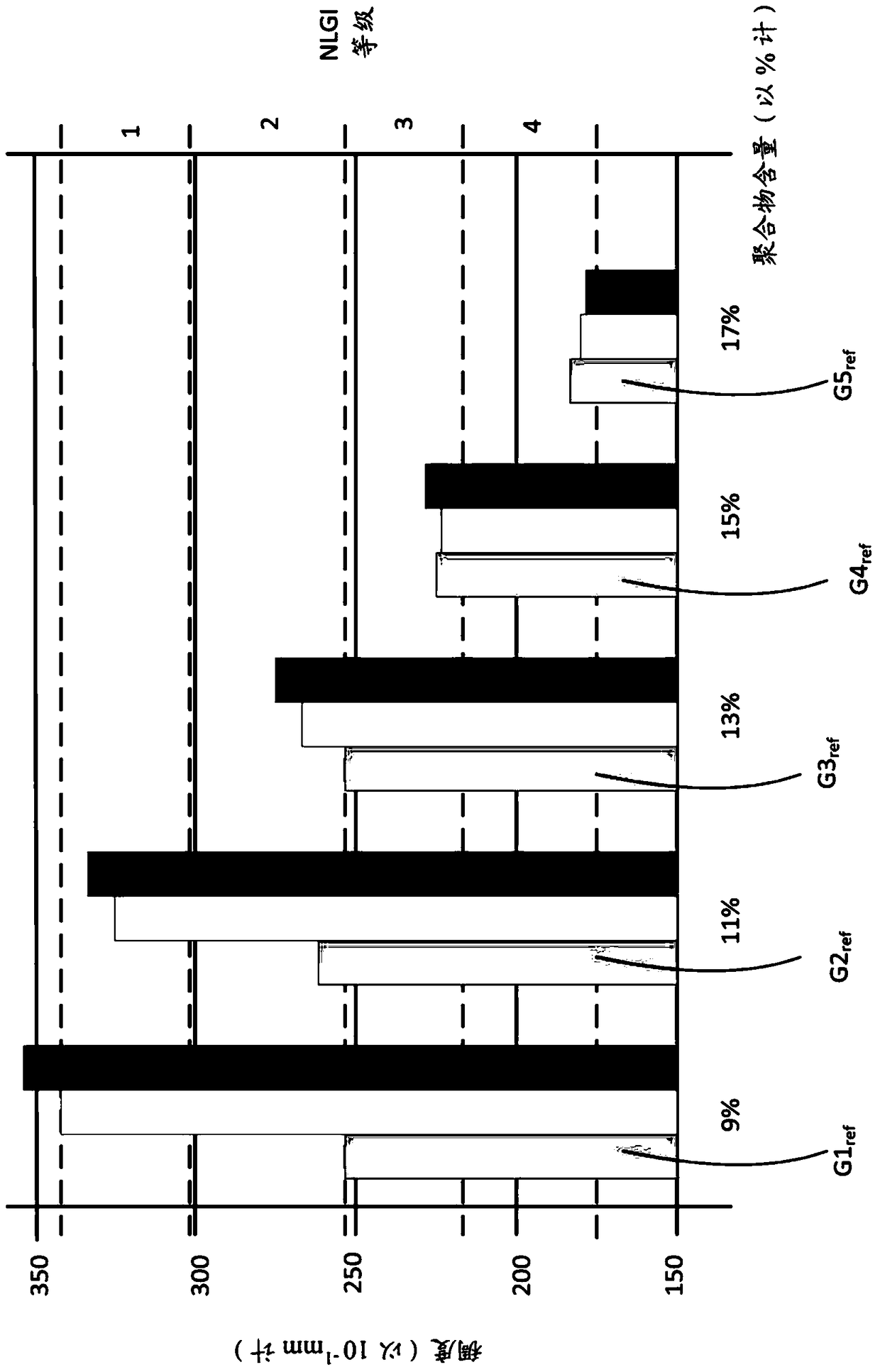

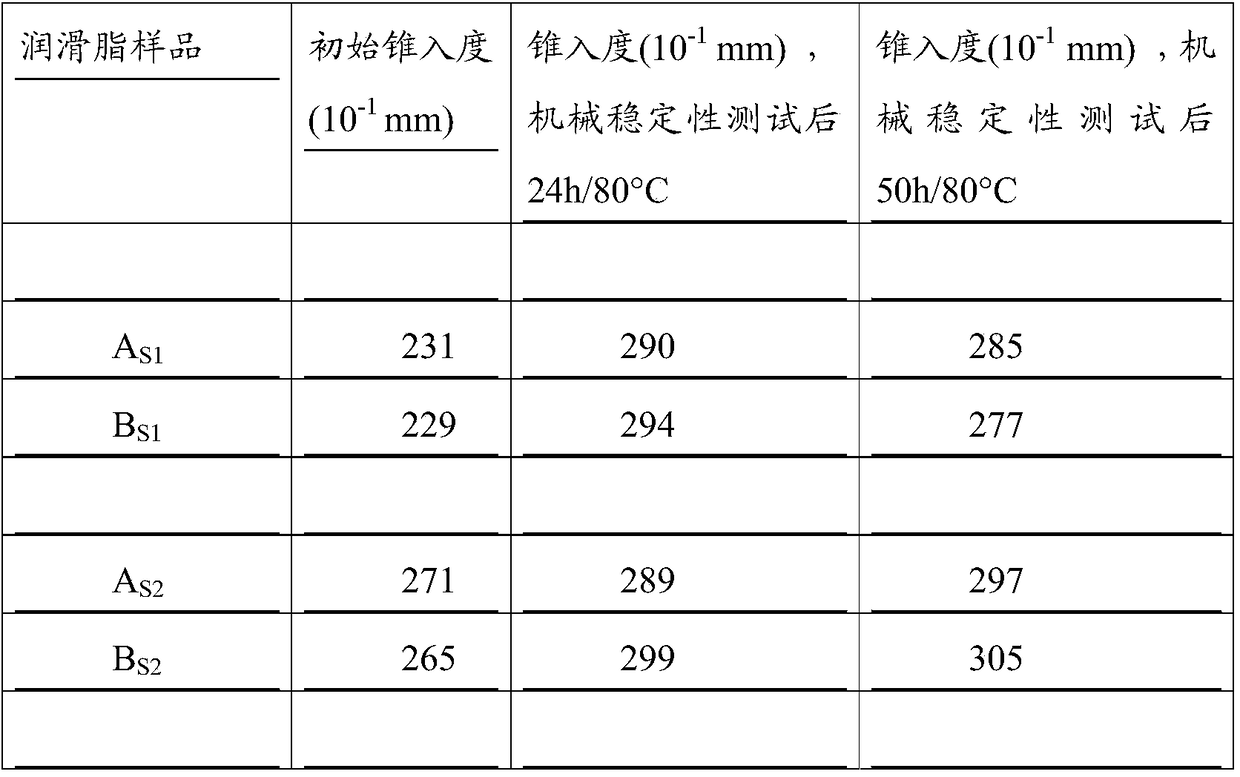

[0057] By mixing a specific amount of high molecular weight polypropylene (average mw.230,000), low molecular weight polypropylene (average mw.82,000), and base oil (polyalphaolefin (PAO), viscosity 68mm 2 / s), and the mixture was heated to 195°C under nitrogen until complete dissolution of the polypropylene occurred to prepare two grease compositions A and B. The weight ratio of low molecular weight polypropylene to high molecular weight propylene was 19 / 1 in each case. The grease composition thus obtained was then rapidly cooled to room temperature within 30 seconds by pouring the mixture onto a metal plate.

[0058] Grease composition A comprised the following ingredients: 13% by weight polypropylene in PAO 200 (polyalphaolefin base oil), no additives. Grease composition B contained the following ingredients: 13% by weight polypropylene in a mineral oil 68 base oil, and the following additives: 0.5% by weight antioxidant; 2.5% by weight anti-corrosion and 2.5% by weight an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com