Quench tube for polymer fiber extrusion

A technology of cooling pipes and polymers, which is applied in fiber processing, complete sets of equipment for the production of artificial threads, filtration and separation, etc., can solve the problems of unsatisfactory air distribution in cooling pipes, and achieve excellent cooling flow uniformity and excellent cooling The effect of flow distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

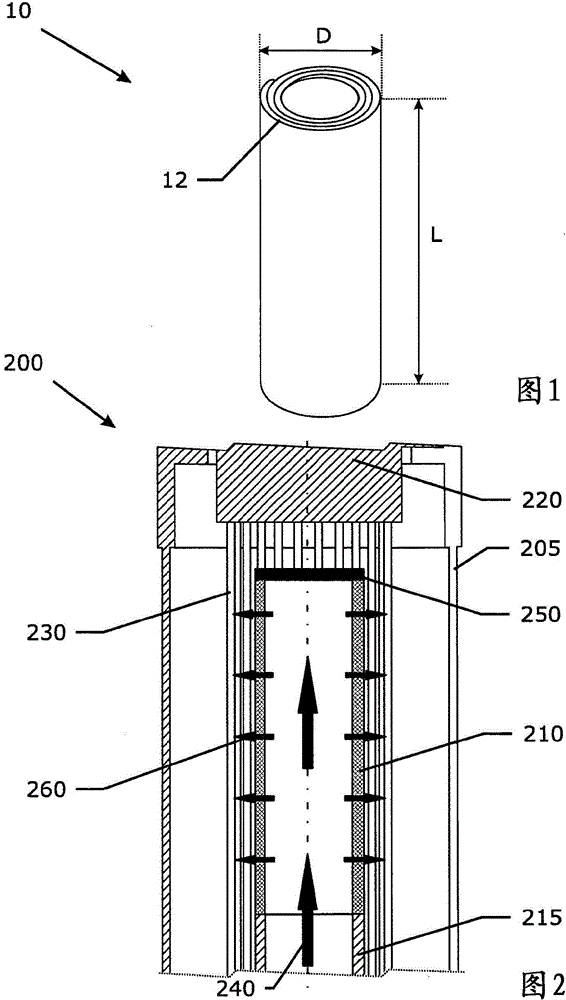

[0052] figure 1 An example of a cooling pipe 10 according to the present invention is shown. L represents the length of the cooling pipe, for example 150mm, and D is its outer diameter. It is manufactured by circular winding (coiling) of an unsintered non-woven stainless steel fiber web around a core of suitable diameter, for example around a spool. Carded, air-laid or wet-laid nonwoven stainless steel fiber webs can advantageously be used. The mesh is wound in order to obtain multiple layers 12 until the desired diameter for the cylindrical shape of the coiled elongated metal fiber structure of the cooling tube is obtained. The number of layers used helps to obtain a uniform cooling air distribution on the outflow surface of the cooling tubes. The metal fibers of such a coiled elongated metal fiber structure are then bonded metallurgically, for example by sintering or by welding, without using additional bonding material. Such welding can be performed, for example, by cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com