Base paper of paper yarn for textile and preparation technique

A preparation process and paper thread technology, which is applied in the field of textile paper thread base paper production, can solve problems such as product yellowing and affecting product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] 1. The raw material formula of the present invention: bleached softwood kraft pulp board accounts for 70%, hemp pulp or bamboo pulp accounts for 25%, and water-soluble fiber (ie synthetic fiber) accounts for 5%.

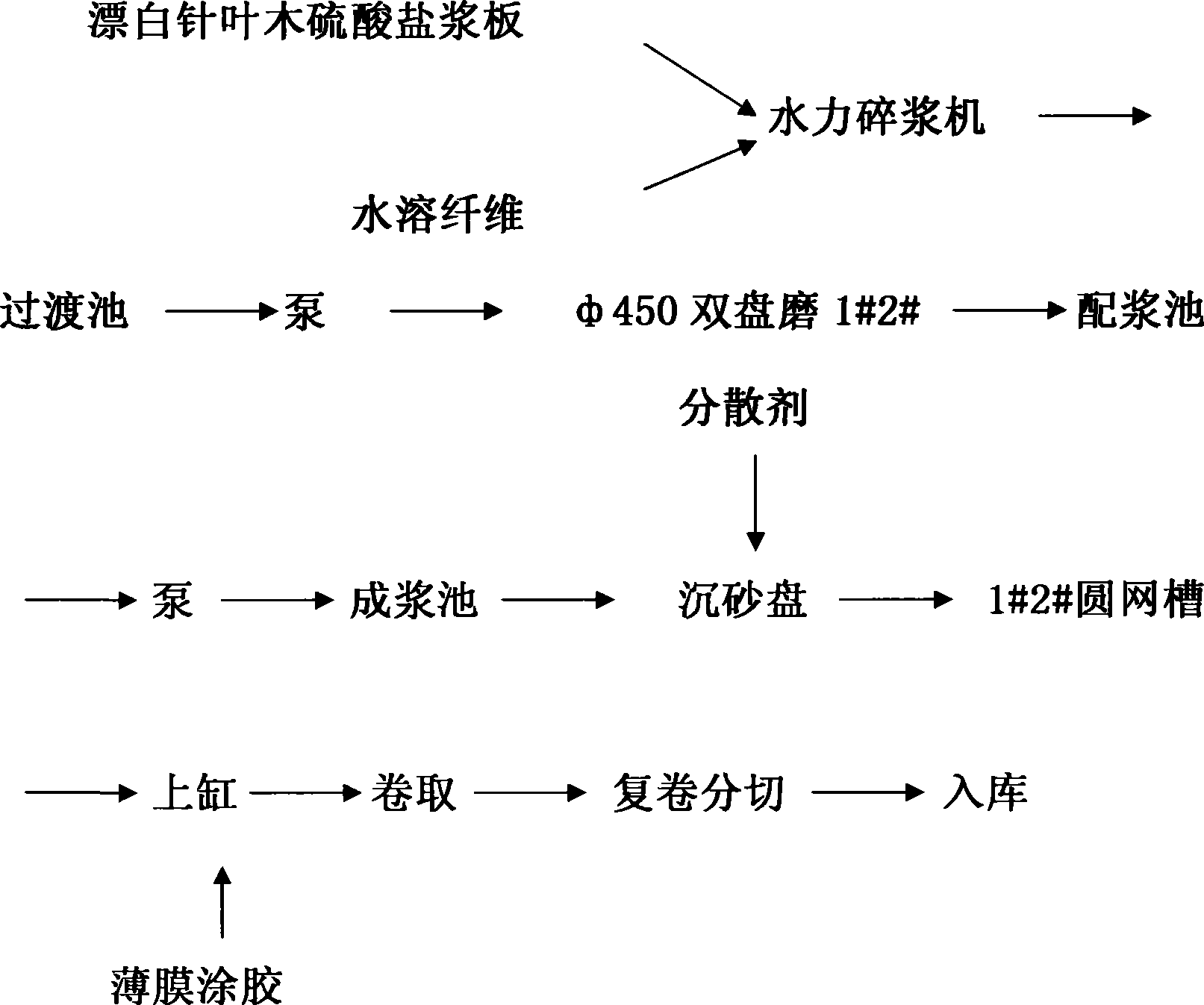

[0026] 2. The preparation process is shown in the figure: it is realized according to the following procedures:

[0027] (1) Bleached softwood kraft pulp board and water-soluble fiber enter the transition tank after being beaten by a hydraulic pulper. The pulp of the hydraulic pulper must be crushed so that the degree of tapping of the pulp reaches more than 60%, and then it is pumped into a double-disc mill for grinding. , The ground material enters the mixing tank, and the hemp pulp or / and bamboo pulp is added to the mixing tank at the same time;

[0028] (2) All materials in the slurry tank are pumped into the grit plate through the slurry tank, and the dispersant is added to the grit plate; the dispersant is composed of polyacrylamide, and the added amount acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com