Automatic detection device of vacuum oil filter for fire resistant oil

An automatic detection device, a technology of vacuum oil filter, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of inability to determine the anti-fuel oil purification treatment, equipment positioning, insecurity, etc., and achieve easy maintenance, simple operation and operation. , The effect of high filtration and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

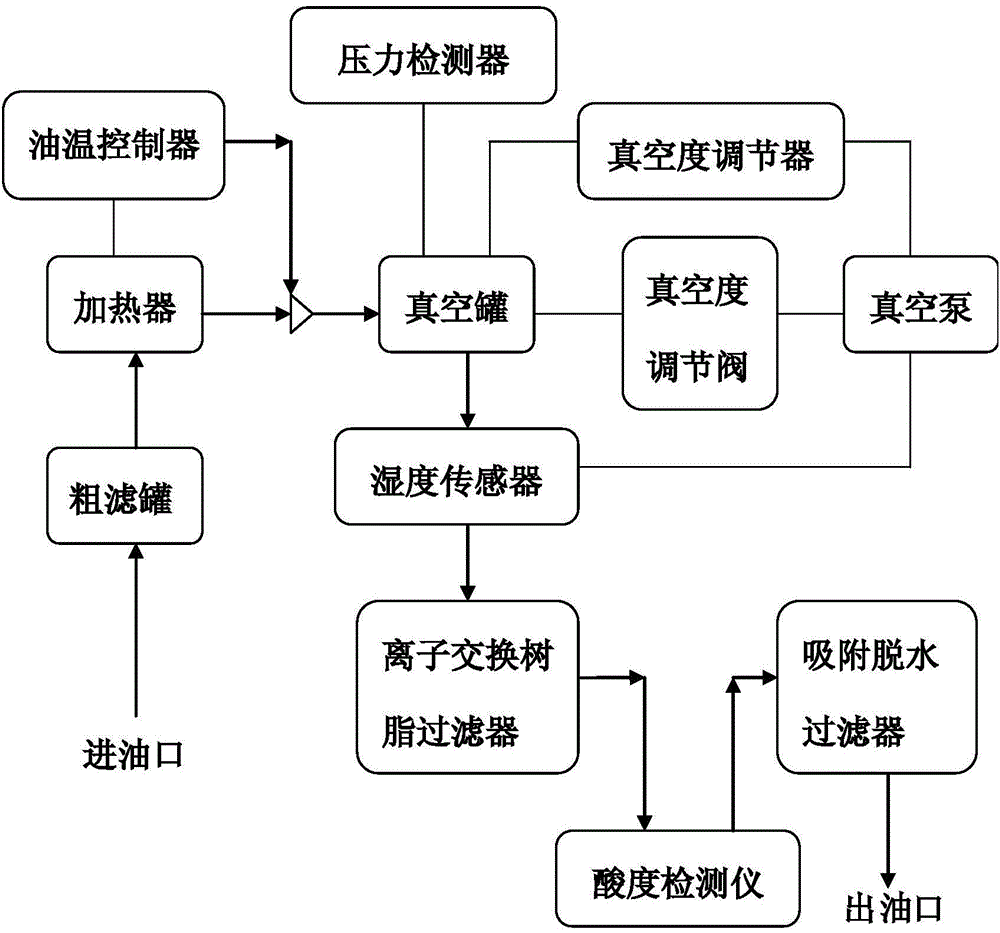

[0011] Such as figure 1 As shown, the automatic detection device of the anti-fuel oil vacuum oil filter includes a coarse filter, an electric heater, an oil temperature controller, a humidity sensor, a pressure detector, a vacuum tank, a vacuum pump and a vacuum regulating valve, and the vacuum tank and the vacuum pump are respectively connected with the control device connection, the pressure detector is connected with the control device, vacuum tank, vacuum pump and vacuum degree regulator respectively, the electric heater is connected with the oil temperature controller, the humidity sensor is arranged inside the vacuum tank, the pressure detector and The vacuum regulator is arranged between the vacuum tank and the vacuum pump.

[0012] In this embodiment, the control device is a PLC controller, the vacuum tank is also equipped with an oil level sensor and a liquid volume sensor, and the PLC controller is respectively connected to the pressure detector, the oil level sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com