Porous sodium alginate-polyglutamic acid gel beads, preparation method thereof, and application of porous sodium alginate-polyglutamic acid gel beads as heavy metal ions absorbent

A technology of polyglutamic acid gel balls and polyglutamic acid gel, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of small adsorption capacity and achieve Improved adsorption effect, simple preparation method, mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

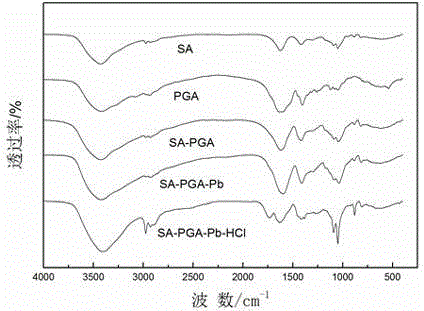

[0022] A kind of preparation method of porous sodium alginate polyglutamic acid gel ball, it comprises the steps:

[0023] 1) Preparation of sodium alginate water-soluble: Weigh 4g of sodium alginate (SA) and add it to 200ml of deionized water, place it on a magnetic stirrer and stir at 1000rpm until the solution is uniform (about 6 hours);

[0024] 2) Preparation of fixative solution: Weigh 50g of calcium chloride and dissolve it in 1000mL of deionized water, and add 2mL of glutaraldehyde with a content of 50% to the obtained calcium chloride solution;

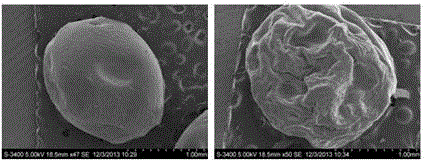

[0025] 3) Add the sodium alginate solution obtained in step 1) into the fixed solution obtained in step 2) drop by drop, preferably at 5 drops / second, and let it stand overnight (12h) after the addition; filter, and use a large amount of gel particles to remove Ion rinsing to remove surface Ca 2+ with Na + , and then vacuum-dried to obtain sodium alginate gel particles. The obtained sodium alginate gel particles were detec...

Embodiment 2

[0034] A kind of preparation method of porous sodium alginate polyglutamic acid gel ball, it comprises the steps:

[0035] 1) Preparation of sodium alginate water-soluble: Add 4g of sodium alginate (SA) into 200g of deionized water, place it on a magnetic stirrer and stir at 1000rpm until the solution is uniform (about 6 hours);

[0036] 2) Preparation of sodium alginate-polyglutamic acid water soluble: add 2g of polyglutamic acid (PGA) to the solution prepared in step 1), and keep stirring until the solution is uniform;

[0037] 3) Preparation of fixative solution: Weigh 50g of calcium chloride and dissolve it in 1000mL of deionized water, add 2mL of glutaraldehyde with a content of 50% to the obtained calcium chloride solution;

[0038] 4) Add the sodium alginate-polyglutamic acid solution obtained in step 2) dropwise into the fixative solution obtained in step 3), preferably at 5 drops / second, and let stand overnight (12h) after the addition; filter, Gel particles are rins...

Embodiment 3

[0041] A kind of preparation method of porous sodium alginate polyglutamic acid gel ball, it comprises the steps:

[0042] 1) Preparation of sodium alginate water-soluble: Add 4g of sodium alginate into 200ml of deionized water, place on a magnetic stirrer and stir at 1000rpm to dissolve until the solution is uniform (about 6 hours of stirring is required);

[0043] 2) Preparation of sodium alginate-polyglutamic acid water soluble: add 2g of polyglutamic acid to the solution prepared in step 1), and keep stirring until the solution is uniform;

[0044] 3) Preparation of fixative solution: Weigh 50g of calcium chloride and dissolve it in 1000mL of deionized water, add 2mL of glutaraldehyde with a content of 50% to the obtained calcium chloride solution;

[0045] 4) Preparation of porous sodium alginate-polyglutamic acid gel: Add 5 mL of toluene to the solution obtained in step 2), stir evenly, and drop the obtained solution into the fixative solution obtained in step 3), prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com