Ordered mesoporous alumina materials loaded with precious metals and their synthesis methods and applications

A mesoporous alumina and synthesis method technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve the problems of difficult uniform dispersion of nanoparticles, low filling rate, and capillary action Small problems, to achieve high catalytic activity and thermal stability, high loading rate, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add 1.0 g of nonionic surfactant Pluronic P123 and 20 mL of ethanol to a 50 mL beaker, and stir at room temperature until Pluronic P123 dissolves. Add 8.4g of citric acid, stir to dissolve, then add 0.006g of platinum acetylacetonate and 3.75g of aluminum nitrate, and stir at room temperature for 10 hours or longer until completely dissolved. After the dissolution is complete, transfer the beaker to an air blast drying oven, place it open, and set the temperature at 40°C, and volatilize the solvent under this condition. After 48 hours, take out the colloid after the solvent has volatilized, transfer the colloid to a porcelain crucible, raise the temperature to 400°C, and roast it in an air atmosphere at this temperature for 4 hours to remove the template agent, and grind it finely with an agate mortar to obtain a powder product, namely It is an ordered mesoporous alumina material loaded with platinum, and the mass percentage of platinum loaded in the material is 0.6% (c...

Embodiment 2

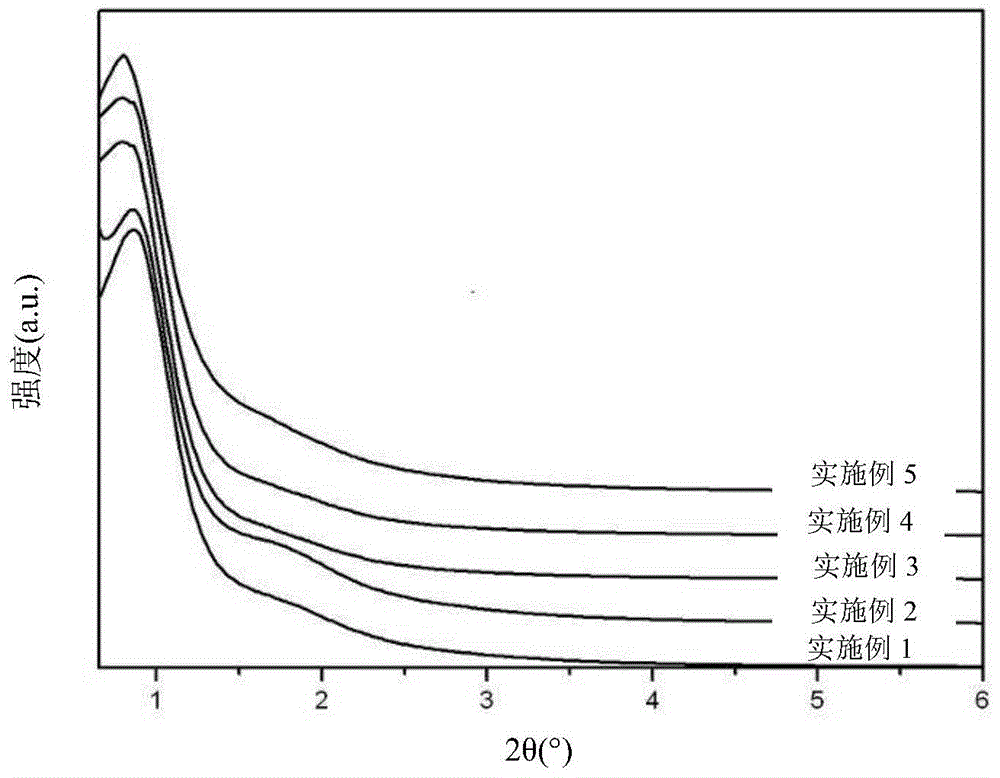

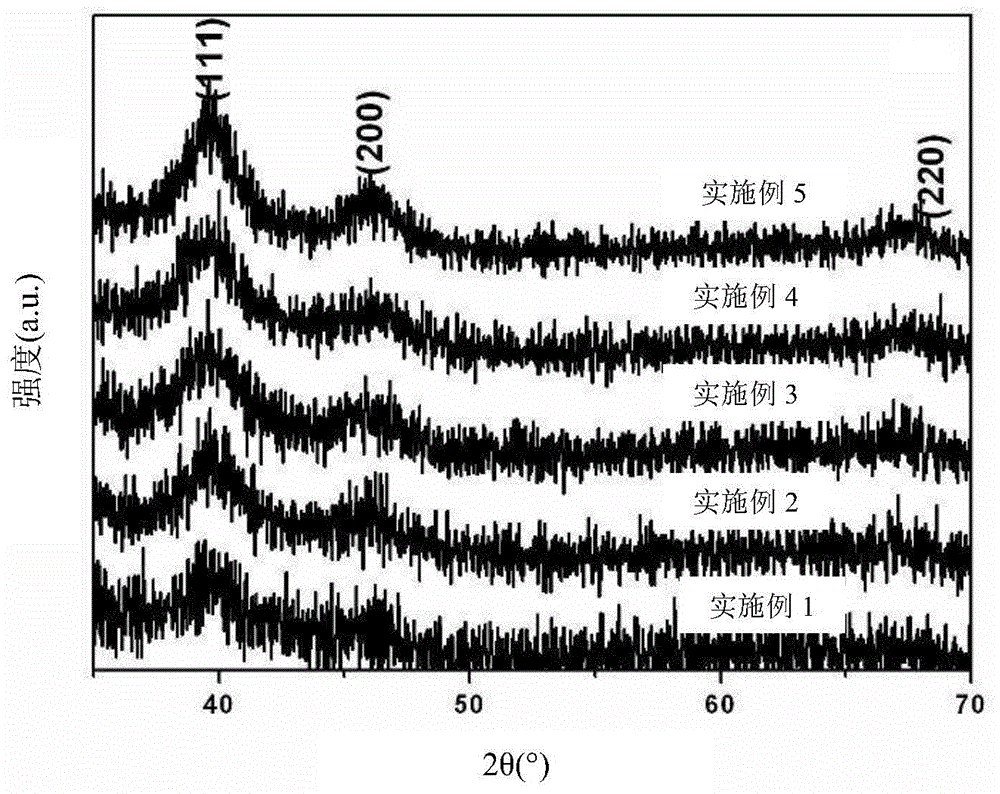

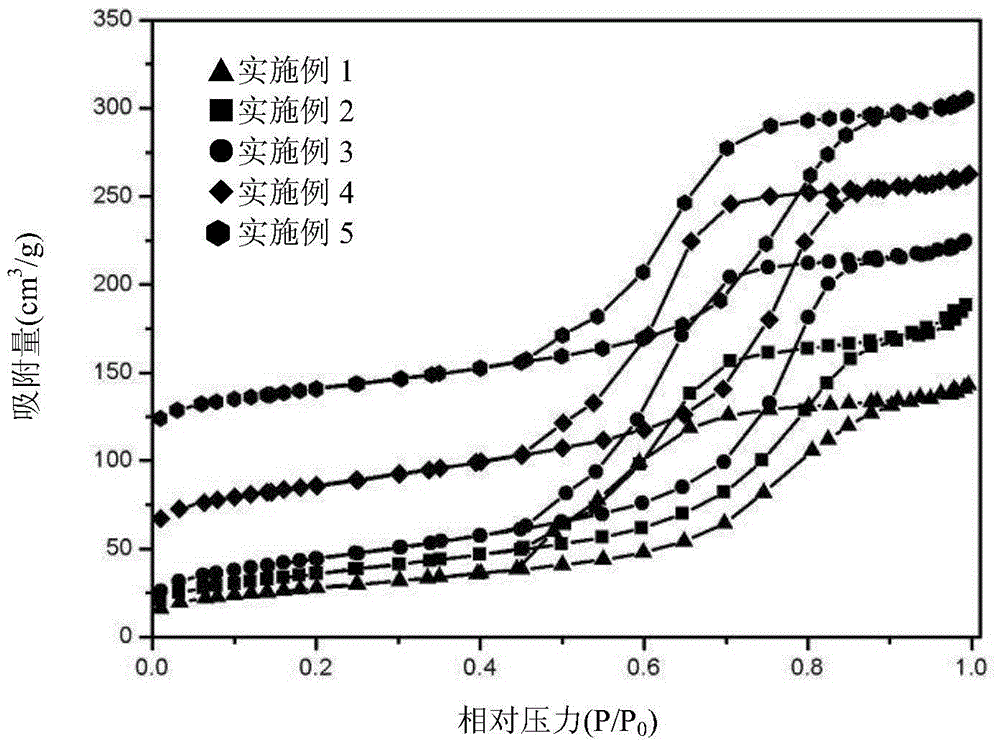

[0054] The operation method is the same as in Example 1, except that the platinum acetylacetonate added is 0.013 g, and the mass percentage of platinum supported is 1.3%. The small angle XRD of the material is shown in figure 1 , wide-angle XRD see figure 2 ; Nitrogen adsorption and desorption curve see image 3 , the pore size distribution see Figure 4 , the pore size of the material varies between 4-6nm; the specific surface area and pore volume are shown in Table 1, and the transmission electron microscope (TEM) photos are shown in Figure 6 .

Embodiment 3

[0056] The operation method is the same as in Example 1, except that the platinum acetylacetonate added is 0.021 g, and the mass percentage of platinum supported is 2.1%. The small angle XRD of the material is shown in figure 1 , wide-angle XRD see figure 2 , the nitrogen adsorption-desorption curve is shown in image 3 , the pore size distribution see Figure 4 , the pore size of the material varies between 4-6nm; the specific surface area and pore volume are shown in Table 1, and the transmission electron microscope (TEM) photos are shown in Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com