Explosive rotating machine for press fitting production line

A technology of press-fitting production line and powder spinning machine, which is applied in the direction of nailing tools and manufacturing tools, can solve the problems of small number of nail shooting bullets, low work efficiency, and impermeable drying of explosives, so as to reduce production costs and reduce a Process, the effect of facilitating the organization of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments:

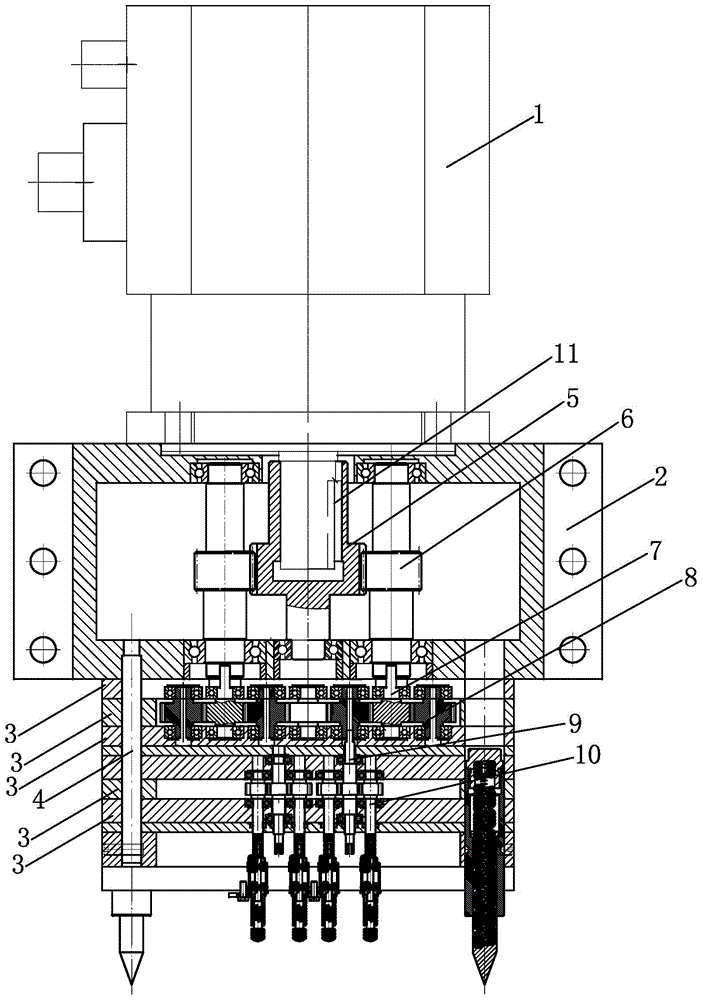

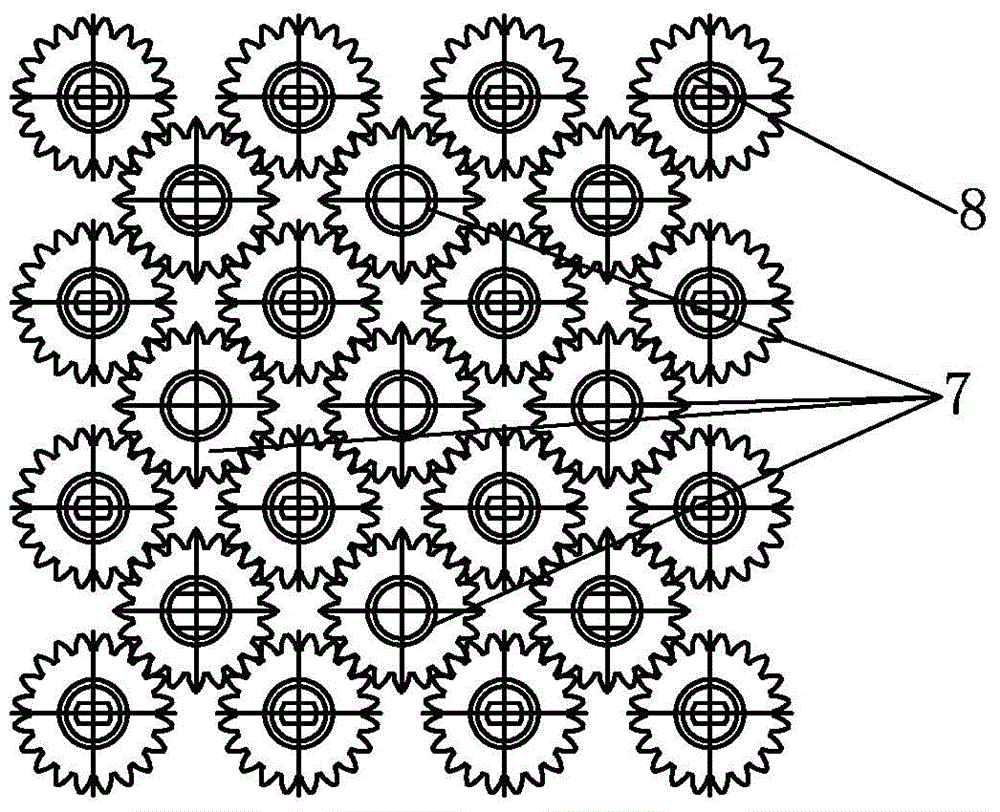

[0019] Such as figure 1 , 2 , 3 and 4, a press-fitting production line spinner, mainly composed of a motor 1, a mounting base 2, a support plate 3, a positioning column 4 and a three-stage gear transmission mechanism. The motor 1 is mounted on a mounting base 2, and a set of support plates 3 are sequentially overlapped on the bottom surface of the mounting base 2, and these support plates 3 are connected and fixed to the mounting base 2 by a set of positioning columns 4. The motor 1 drives a three-stage gear transmission mechanism, which are respectively a first-stage gear transmission mechanism, a second-stage gear transmission mechanism and a third-stage gear transmission mechanism.

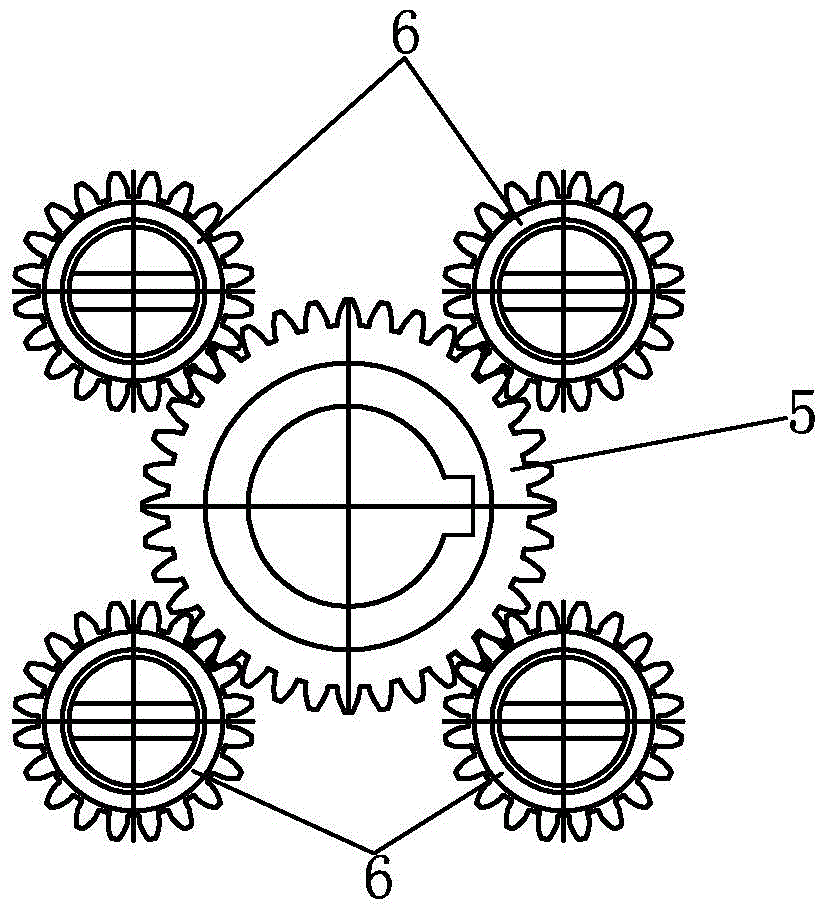

[0020] Such as figure 1 , 2 As shown, the first-stage gear transmission mechanism is mainly composed of a first-stage driving gear shaft 5, a first-stage driven gear shaft 6 and a key 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com