Extraction method of p-aminobenzoic acid

A para-aminobenzoic acid and extraction technology, which is applied in chemical instruments and methods, liquid solution solvent extraction, preparation of organic compounds, etc., can solve the problems of unsuitable industrial application, difficulty in regeneration of adsorbents, cumbersome back-extraction process, etc. Mild operating conditions, good solubility, and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

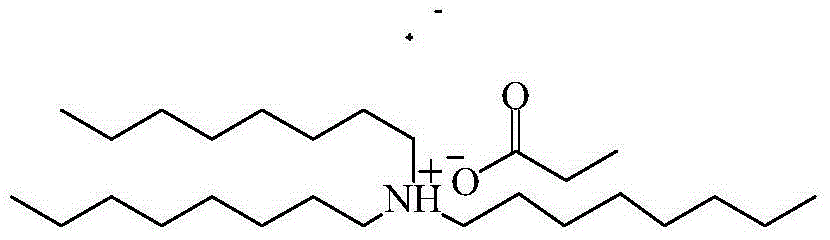

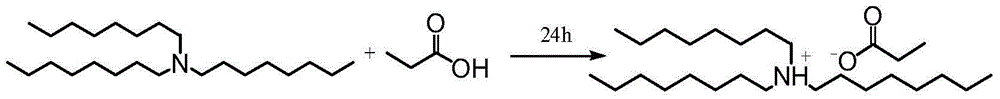

[0031] Mix 1mL of N,N,N-trioctylammonium propionate protic ionic liquid with 3mL of p-aminobenzoic acid aqueous solution with a concentration of 800ppm at pH=7, stir at 25°C for 5min at a stirring rate of 500rpm, and let stand to separate After layering, the concentration of p-aminobenzoic acid in the water layer after extraction was detected by an ultraviolet spectrophotometer, and the extraction rate of the ionic liquid was calculated to be 86.38%.

Embodiment 2

[0033] Mix 1mL of N,N,N-trioctylammonium propionate protic ionic liquid with 3mL of p-aminobenzoic acid aqueous solution with a concentration of 800ppm at pH=7, stir at 25°C for 10min at a stirring rate of 500rpm, and let stand to separate After layering, the concentration of p-aminobenzoic acid in the water layer after extraction was detected with an ultraviolet spectrophotometer, and the extraction rate of the ionic liquid was calculated to be 86.66%.

Embodiment 3

[0035] Mix 1mL of N,N,N-trioctylammonium propionate protic ionic liquid with 3mL of p-aminobenzoic acid aqueous solution with pH=7 and concentration of 800ppm, stir at 25°C for 20min at a stirring speed of 500rpm, and let stand to separate After layering, the concentration of p-aminobenzoic acid in the water layer after extraction was detected with an ultraviolet spectrophotometer, and the extraction rate of the ionic liquid was calculated to be 86.80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extraction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com