Method for producing trans-4-hydroxyproline from glucose in fermentation manner

A kind of hydroxyproline, trans technology, applied in the field of microbial genetic engineering, can solve problems such as a large number of wastes, and achieve the effect of broad industrial application prospects and important industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Obtaining of recombinant plasmid (pET28a-Ptrp2-proBA2) containing proBA2

[0028] Take the strain containing the target plasmid stored in the laboratory for activation, and cultivate it at 37°C and 220rpm for 12-16 hours. The cultured bacterial liquid was taken to extract the plasmid, and all operations were carried out in strict accordance with the instructions.

Embodiment 2

[0029] Example 2: Obtaining of recombinant plasmid (pUC19-Ptrp2-hyp) containing hyp

[0030] Take the strain containing the target plasmid stored in the laboratory for activation, and cultivate it at 37°C and 220rpm for 12-16 hours. The cultured bacterial liquid was taken to extract the plasmid, and all operations were carried out in strict accordance with the instructions.

Embodiment 3

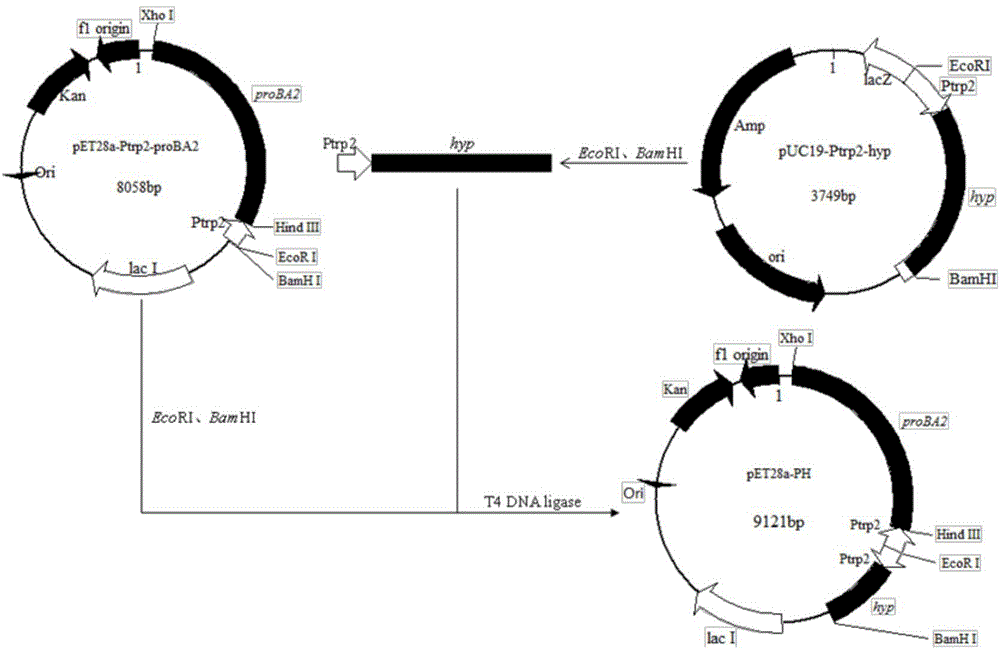

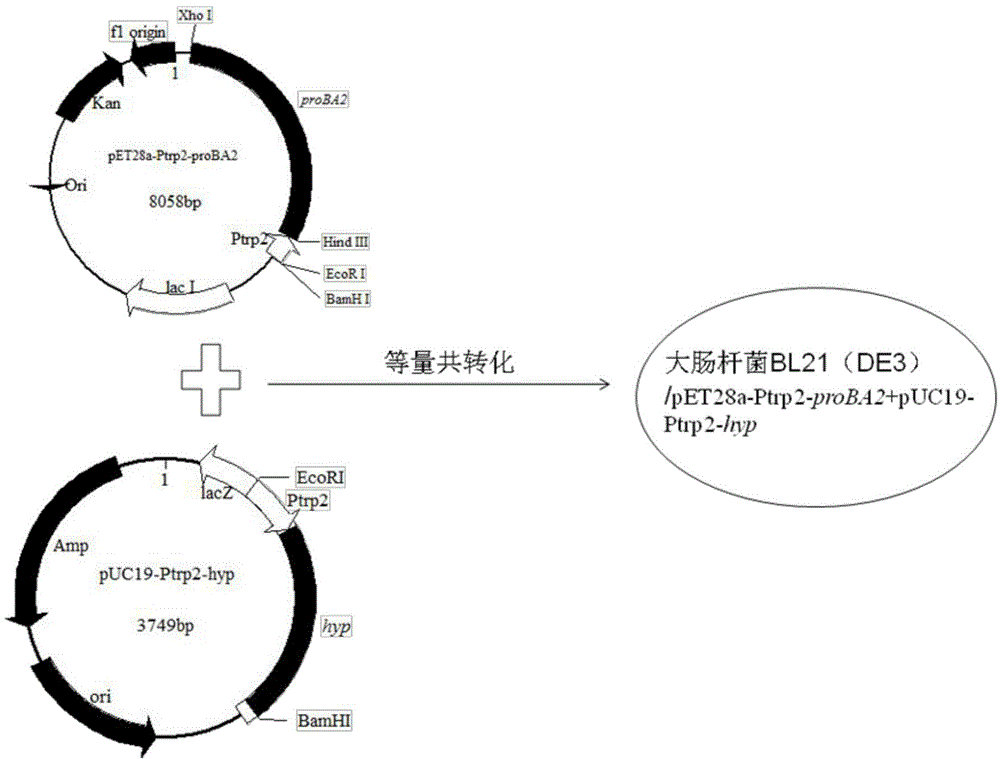

[0031] Embodiment 3: the single expression vector pET28a-PH that contains two kinds of genes and the acquisition of recombinant bacteria

[0032] Treat pET28a-Ptrp2-proBA2 and pUC19-Ptrp2-hyp with two enzymes, EcoRI and BamHI, respectively, and recover the linear pET28a-Ptrp2-proBA2 and Ptrp2-hyp fragments from the gel of the digested products. After connecting overnight at 16°C, transfer 10 μL of the connection solution into Escherichia coli JM109, pick the transformed single colony and culture it to extract the plasmid for enzyme digestion verification, and verify that the correct recombinant plasmid is pET28a-PH.

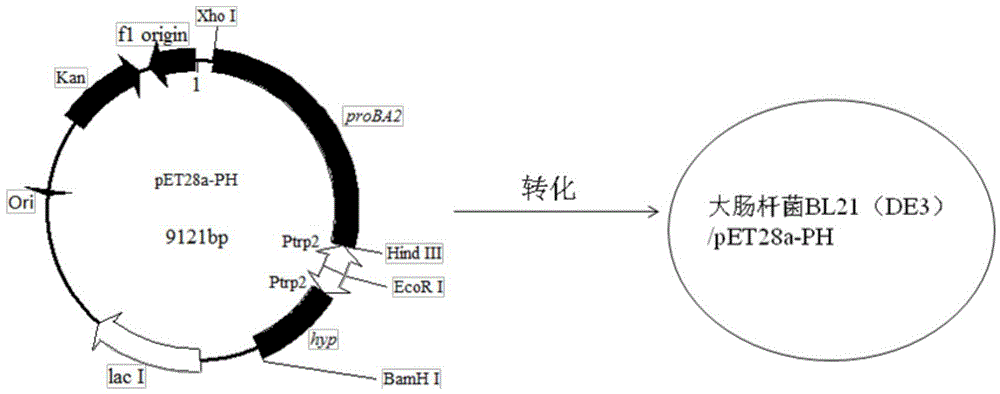

[0033] The pET28a-PH recombinant plasmid was transformed into Escherichia coli BL21(DE3) to obtain recombinant Escherichia coli BL21(DE3) / pET28a-PH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com