Light soil side wide roadbed structure for railway

A light soil and railway technology, applied in infrastructure engineering, roads, excavation, etc., can solve the problems of additional settlement of existing roadbeds, large additional loads of railway roadbeds, etc., to reduce settlements, improve stability, and strengthen structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

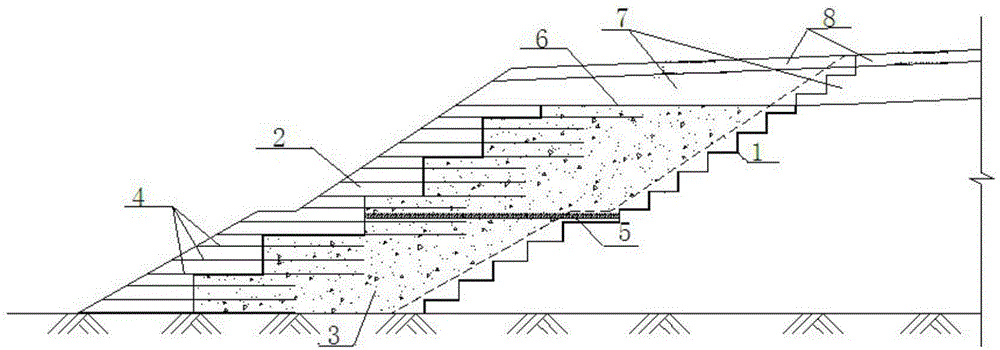

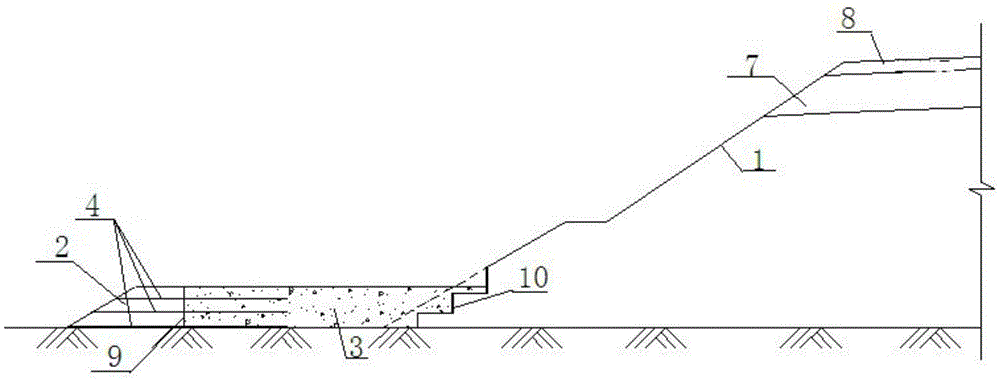

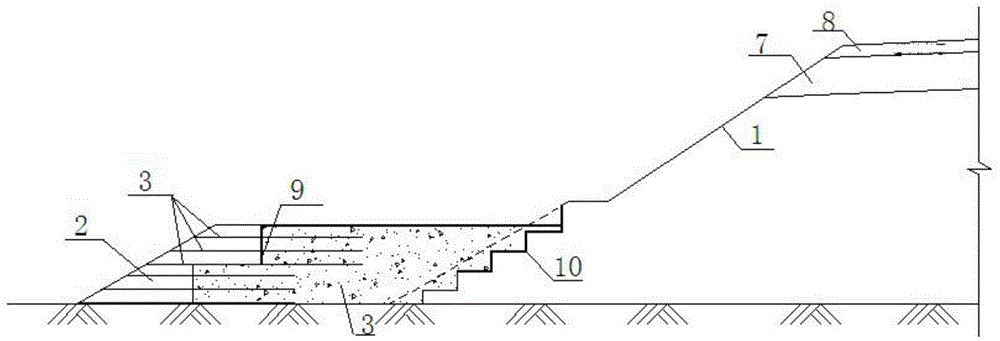

[0026] Such as figure 1 As shown, the present invention provides a kind of railway light soil side wide embankment structure, comprising existing railway slope 1 and new side wide filling embankment 2, existing railway side slope 1 and newly built side wide filling embankment 2 Pouring with light soil layer 3. The contact surface between the light soil layer and the embankment is stepped, and the contact surface between the railway slope and the light soil layer is stepped. The lightweight soil used in the light soil layer 3 has a bulk density of 7-10kN / m3 and a compressive strength of 0.8-1.5MPa; its durability is the same as the life of the main project, and it does not contain harmful and flammable substances to avoid environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com