Electromagnetic damping composite sliding plate support

A technology of electromagnetic damping and composite boards, which is applied in construction, building components, shockproof, etc., can solve the problems that the skateboard support cannot provide damping, low-level rigidity and horizontal deformation ability, and the skateboard support cannot input and adjust damping parameters, etc., to achieve damping High energy consumption, low cost and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

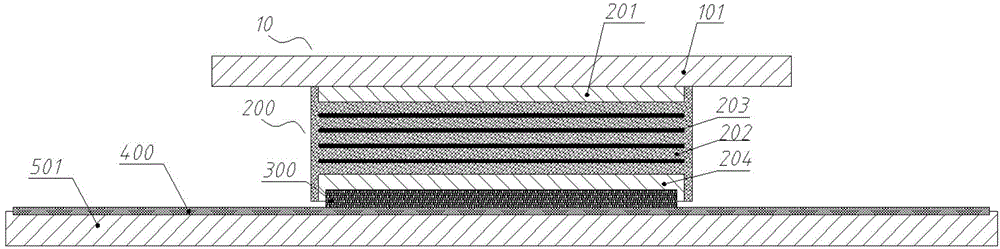

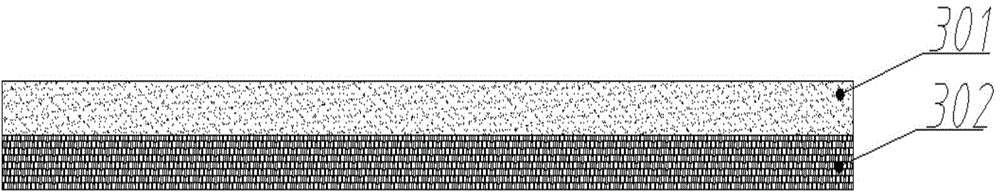

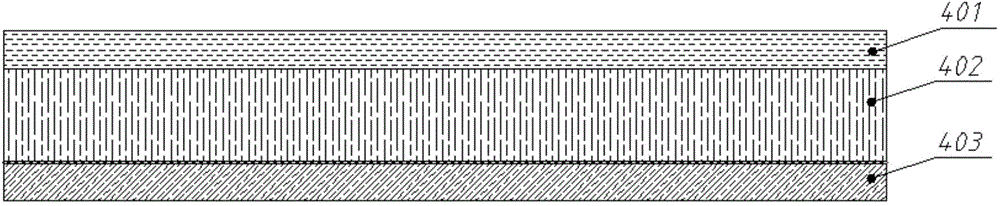

[0019] Such as figure 1 As shown, the electromagnetic damping composite skateboard support 10 of this embodiment includes an upper connection plate 101 , an elastic support part 200 , a permanent magnet sliding body 300 , an eddy current sliding composite plate 400 and a lower connection plate 501 . The elastic support part 200 is arranged under the upper connecting plate 101 and is affixed to it. The elastic support part 200 is composed of the upper sealing plate 201, the lower sealing plate 204 and the elastic joints alternately stacked between the upper sealing plate 201 and the lower sealing plate 204. Body 202 and stiffening plate 203. The permanent magnet sliding body 300 is embedded and fixedly connected to the lower part of the elastic support part 200. The permanent magnet sliding body 300 is composed of a permanent magnet 301 and a slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com