A method for reducing the construction risk of subway shield tunnel entrance

A subway shield and portal technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problem of increased communication and design change extra costs, high requirements for grouting reinforcement and water sealing, and short embedded length of portal rings and other problems, to achieve the effect of easy guarantee of processing accuracy, reduction of construction risk, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

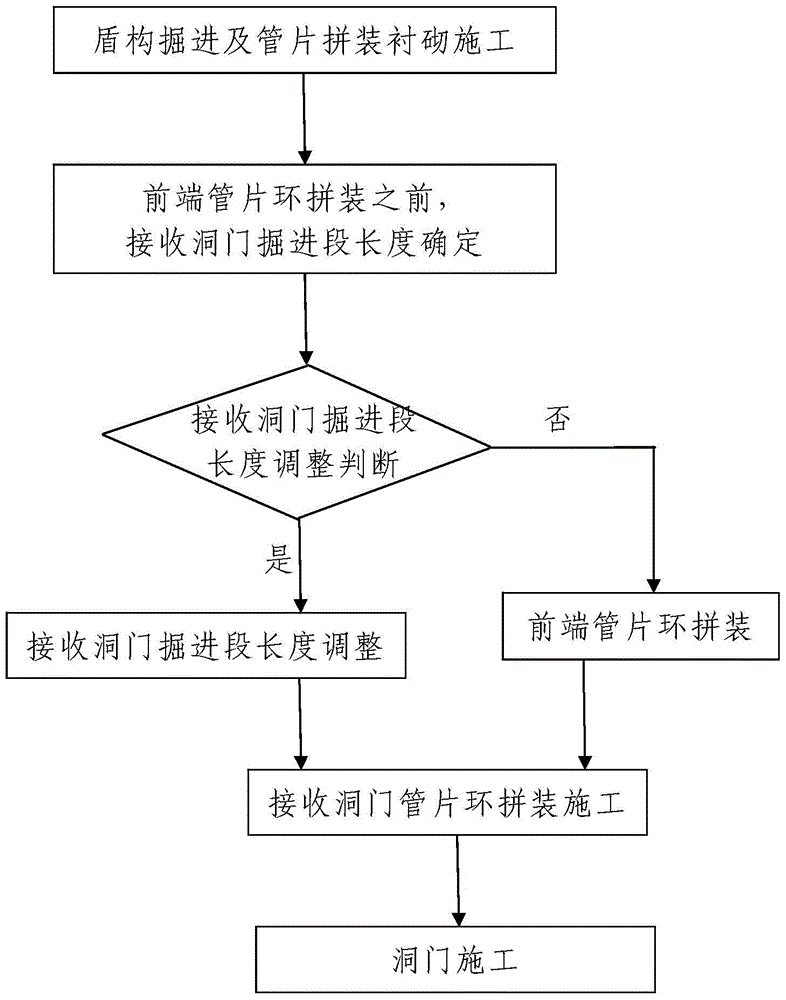

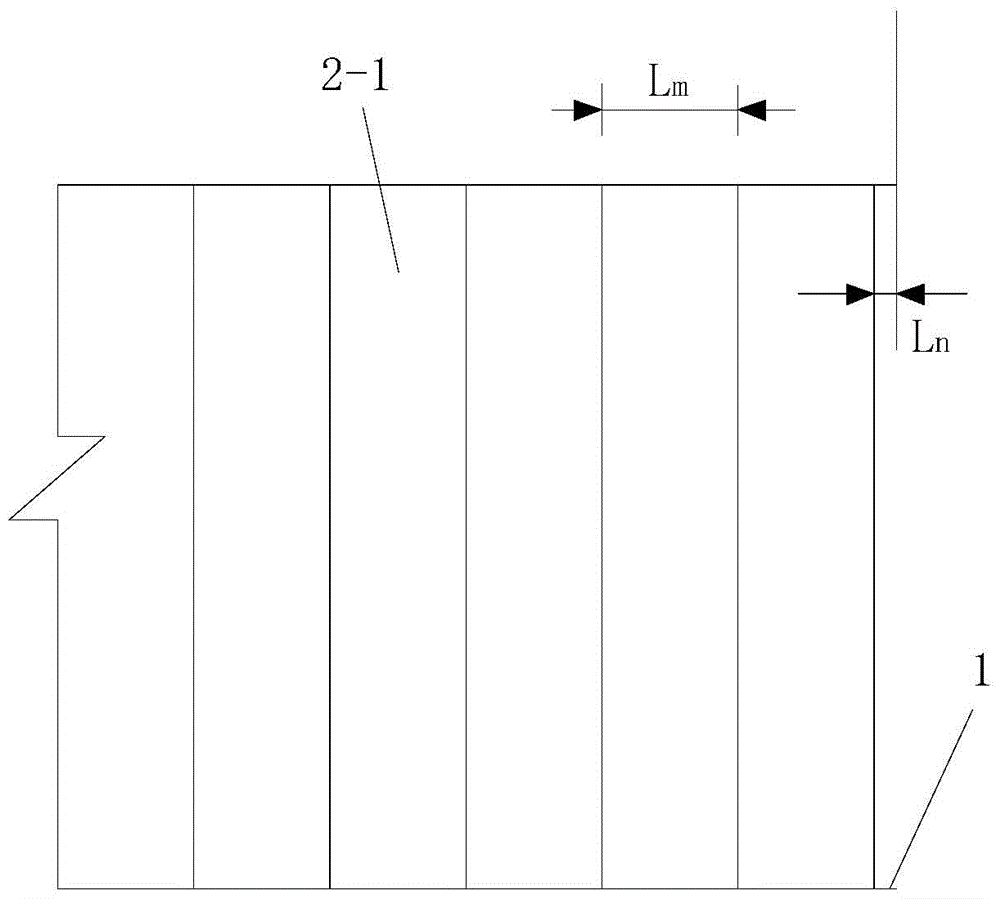

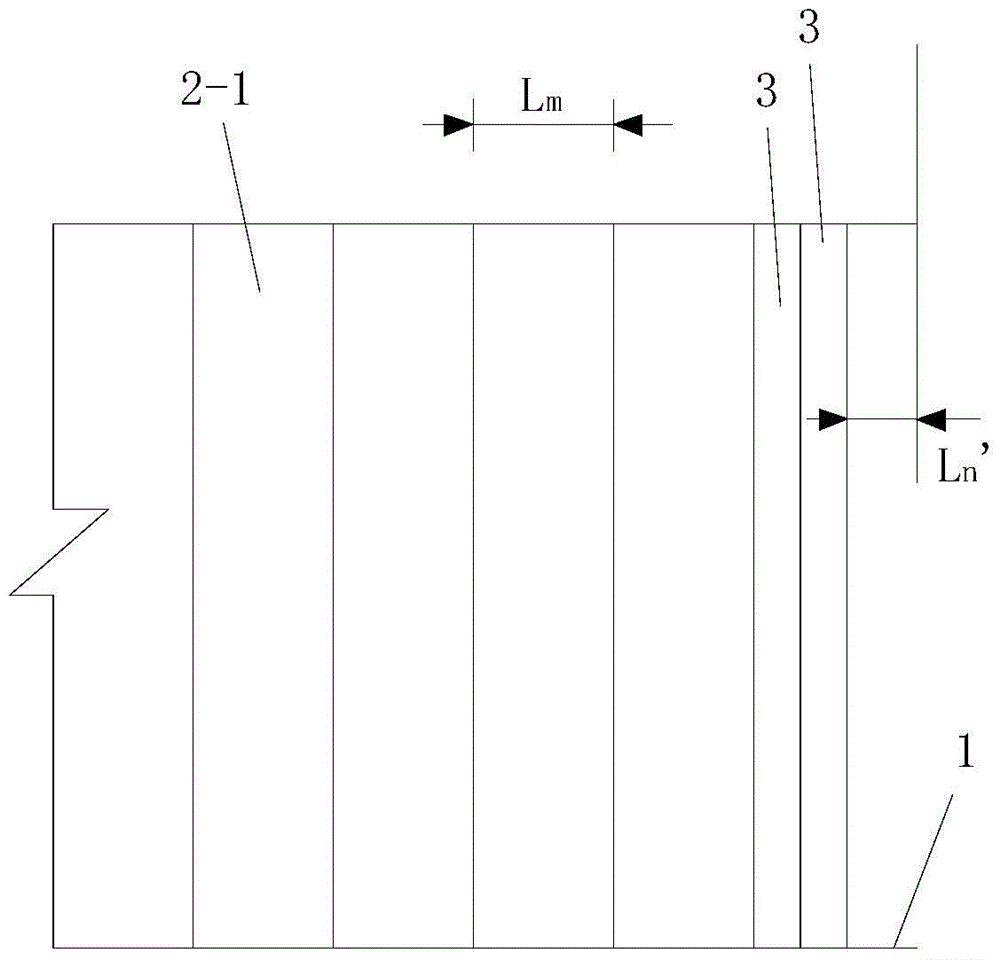

[0046] Such as figure 1 Shown is a method for reducing the construction risk of the subway shield tunnel portal. The subway shield tunnel 1 under construction is divided into the excavation excavation section, the main excavation section and the receiving portal excavation section from the back to the front along the excavation direction. The main excavation section is located between the initial excavation section and the receiving portal excavation section, and the portals at the front and rear ends of the subway shield tunnel 1 are respectively the receiving portal and the starting portal; the pipes installed in the initial excavation section The segment ring is the segment ring of the starting portal, and the length of the initial excavation section is 400mm-800mm; the shield segments installed in the main excavation section are all main segment segments, and the tunnel segments in the main excavation section are The segment rings are all assembled from a plurality of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com