Device and method for analyzing trace impurities in gas

A technology of trace impurities and analysis devices, which is applied in the field of gas chromatography analysis, can solve problems such as cumbersome operations, and achieve the effects of simplifying sample injection operations, speeding up detection speed, and reducing purchase and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

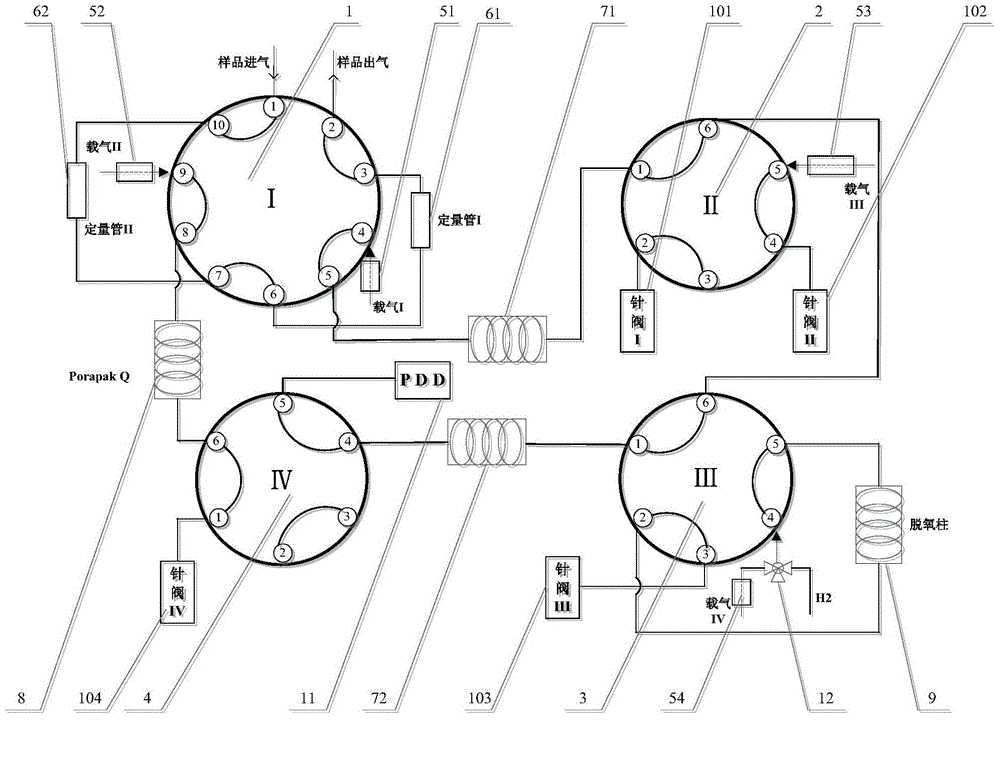

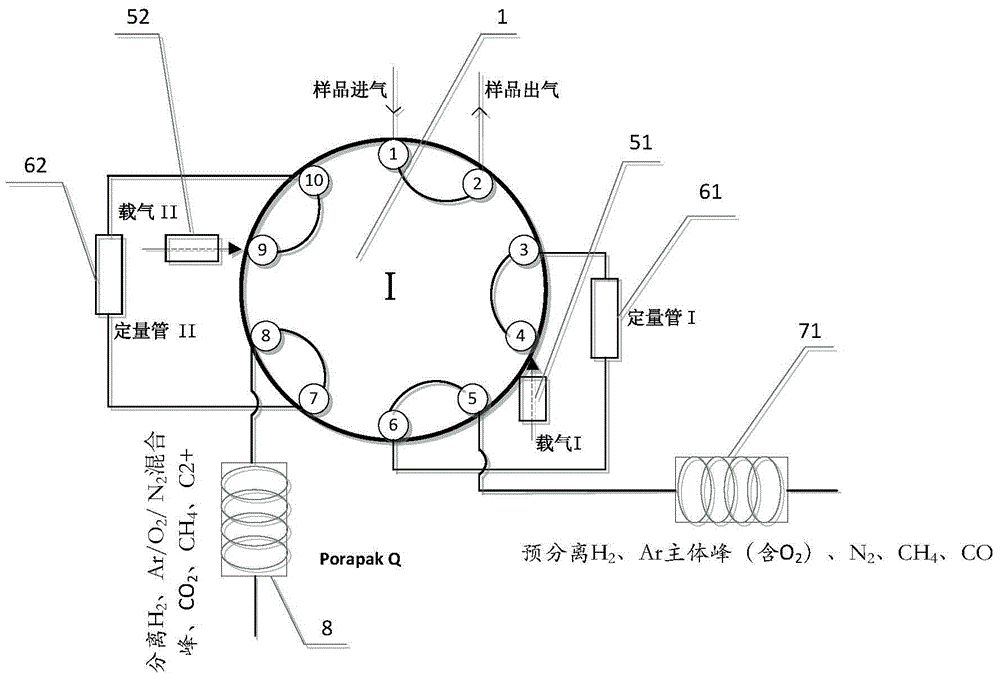

[0108] combine Figure 2 to Figure 9 , taking the analysis of impurity components such as hydrogen, nitrogen, methane, carbon dioxide and carbon monoxide in high-purity argon as an example to illustrate the trace impurities in high-purity gases such as hydrogen, neon, argon, nitrogen, krypton, and helium Analysis of components. Including the following steps:

[0109] a. Carry out a sample injection operation, switch valve I1 to reconnect the pipeline, carrier gas I will bring the sample in the quantitative tube I61 into the first molecular sieve column 71, and pre-separate H 2 , Ar main peak (including O 2 ), N 2 、CH 4 , CO component; the sample in the carrier gas II and the quantitative tube II62 enters the Porapak Q column 8, and the CO 2 with H 2 , Ar / O 2 / N 2 mixed peak, CH 4 , C2+, etc. are separated; such as figure 2 shown.

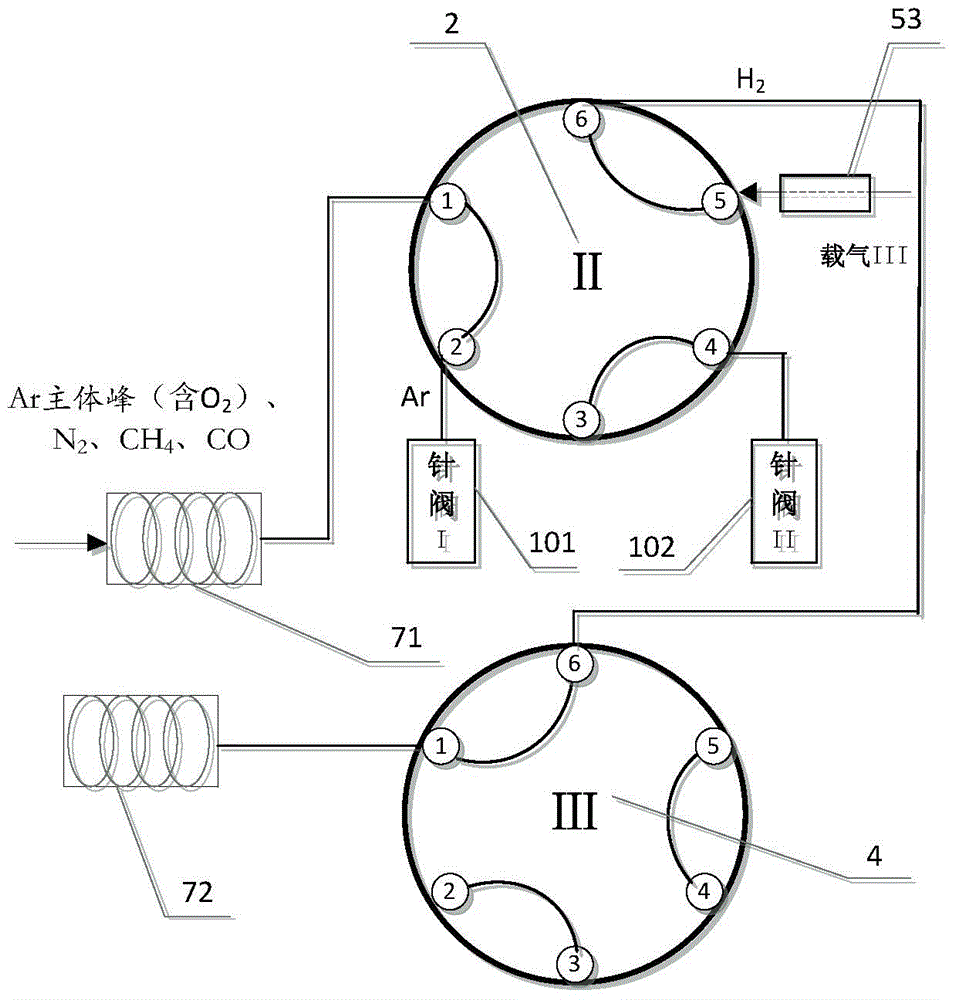

[0110] b. After being pre-separated by the first molecular sieve column 71, H 2 After passing the switching valve II2, switch the swit...

Embodiment 2

[0117] For the analysis of high-purity oxygen / ultra-pure oxygen, it is necessary to switch the gas path so that the sample gas passes through the deoxygenation column 9 to remove oxygen.

[0118] combine Figure 10 ~ Figure 15 , taking the analysis of hydrogen, argon, nitrogen, methane, carbon dioxide, and carbon monoxide impurity components in high-purity oxygen as an example, the analysis method of high-purity oxygen and ultra-pure oxygen is described, including the following steps:

[0119] a. Carry out a sample injection operation, switch valve I1 to reconnect the pipeline, carrier gas I will bring the sample in the quantitative tube I61 into the first molecular sieve column 71, and pre-separate H 2 , O 2 Main peak (including Ar), N 2 、CH 4 , CO component; the sample in the carrier gas II and the quantitative tube II62 enters the Porapak Q column 8, and the CO 2 with H 2 , Ar / O 2 / N 2 mixed peak, CH 4 , C2+, etc. are separated; such as Figure 10 shown.

[0120] ...

Embodiment 3

[0125] When analyzing the oxygen-containing mixed gas, the main component gas other than oxygen is cut at the switching valve II2, and the switching valve III3 is switched to make the sample gas pass through the deoxygenation column 9 to remove oxygen.

[0126] combine Figure 16 ~ Figure 24 , taking the analysis of the impurity components of hydrogen, argon, methane, carbon dioxide, and carbon monoxide in the oxygen-nitrogen mixed gas as an example, the analysis method of the oxygen-containing mixed gas is described, including the following steps:

[0127] a. Carry out a sample injection operation, switch valve I1 to reconnect the pipeline, carrier gas I will bring the sample in the quantitative tube I61 into the first molecular sieve column 71, and pre-separate H 2 , O 2 Main peak (including Ar), N 2 Main peak, CH 4 , CO component; the sample in the carrier gas II and the quantitative tube II62 enters the Porapak Q column 8, and the CO 2 with H 2 , Ar / O 2 / N 2 mixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com