Preparation method of nickel ferrite magnetic nanocomposite material

A technology of magnetic nano and composite materials, applied in nickel compounds, nanotechnology, nanotechnology, etc., can solve problems such as limiting the development of miniaturization of magnetic storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

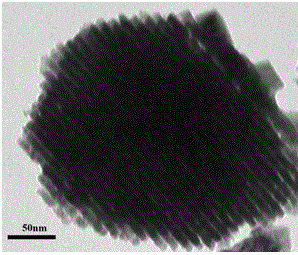

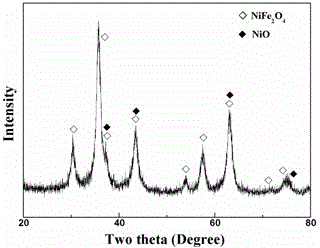

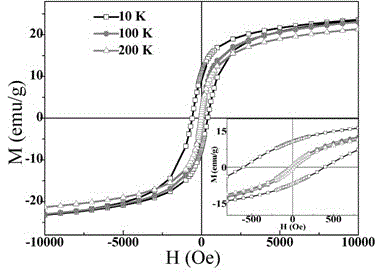

[0012] Specific implementation mode 1: First obtain ordered NiFe by nano-replication method 2 o 4 Magnetic nanomaterials: 2 g SBA-15, 6.73 g Fe(NO 3 ) 3 9H 2 O and 2.42 g Ni(NO 3 ) 2 6H 2 O was put into a polytetrafluoroethylene cup, added alcohol and stirred until dry, then added n-hexane and stirred until it was powdered, and then put it into a muffle furnace for calcination at 700°C for 6 h. After the sample is cooled, wash it twice with 1.6 mol / L hot NaOH to remove the template, centrifuge and wash it with deionized water until it is neutral, and dry it with alcohol suction to obtain NiFe 2 o 4 magnetic nanomaterials. Secondly, NiO / NiFe is obtained by impregnation method 2 o 4 Magnetic Nanocomposites: According to N 2 NiFe measured by physical adsorption instrument 2 o 4 Pore volume of magnetic nanomaterials, calculate the Ni(NO 3 ) 2 6H 2 O quality. Weigh 0.31g Ni(NO 3 ) 2 6H 2 O, 0.982 g NiFe 2 o 4 Put it into a polytetrafluoroethylene cup, add ...

specific Embodiment approach 2

[0013] Specific implementation mode 2: First obtain ordered NiFe by nano-replication method 2 o 4 Magnetic nanomaterials: 2 g SBA-15, 6.73 g Fe(NO 3 ) 3 9H 2 O and 2.42 g Ni(NO 3 ) 2 6H 2 O was put into a polytetrafluoroethylene cup, added alcohol and stirred until dry, then added n-hexane and stirred until it was powdered, and then put it into a muffle furnace for calcination at 700°C for 6 h. After the sample is cooled, wash it twice with 1.6 mol / L hot NaOH to remove the template, centrifuge and wash it with deionized water until it is neutral, and dry it with alcohol suction to obtain NiFe 2 o 4 Magnetic Nanomaterials. Secondly, NiO / NiFe is obtained by impregnation method 2 o 4 Magnetic Nanocomposites: According to N 2 NiFe measured by physical adsorption instrument 2 o 4 Pore volume of magnetic nanomaterials, calculate the Ni(NO 3 ) 2 6H 2 O quality. Weigh 0.31g Ni(NO 3 ) 2 6H 2 O, 0.982 g NiFe 2 o 4 Put it into a polytetrafluoroethylene cup, add ...

specific Embodiment approach 3

[0014] Specific implementation mode 3: first obtain ordered NiFe by nano-replication method 2 o 4 Magnetic nanomaterials: 2 g SBA-15, 6.73 g Fe(NO 3 ) 3 9H 2 O and 2.42 g Ni(NO 3 ) 2 6H 2 O was put into a polytetrafluoroethylene cup, added alcohol and stirred until dry, then added n-hexane and stirred until it was powdered, and then put it into a muffle furnace for calcination at 700°C for 6 h. After the sample is cooled, wash it twice with 1.6 mol / L hot NaOH to remove the template, centrifuge and wash it with deionized water until it is neutral, and dry it with alcohol suction to obtain NiFe 2 o 4 magnetic nanomaterials. Secondly, NiO / NiFe is obtained by impregnation method 2 o 4Magnetic Nanocomposites: According to N 2 NiFe measured by physical adsorption instrument 2 o 4 Pore volume of magnetic nanomaterials, calculate the Ni(NO 3 ) 2 6H 2 O quality. Weigh 0.31 g Ni(NO 3 ) 2 6H 2 O, 0.982 g NiFe 2 o 4 Put it into a polytetrafluoroethylene cup, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com