Supporting structure for body of epoxy cast dry-type transformer

A dry-type transformer, epoxy casting technology, applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, electrical components, etc. The distance between the body and the ground becomes smaller and other problems, so as to reduce the length of the copper bar, ensure the reliability, and reduce the temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

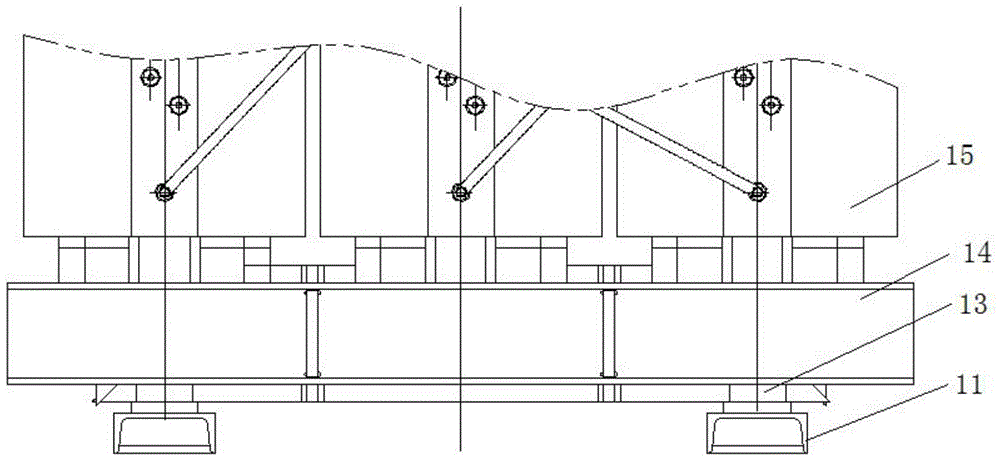

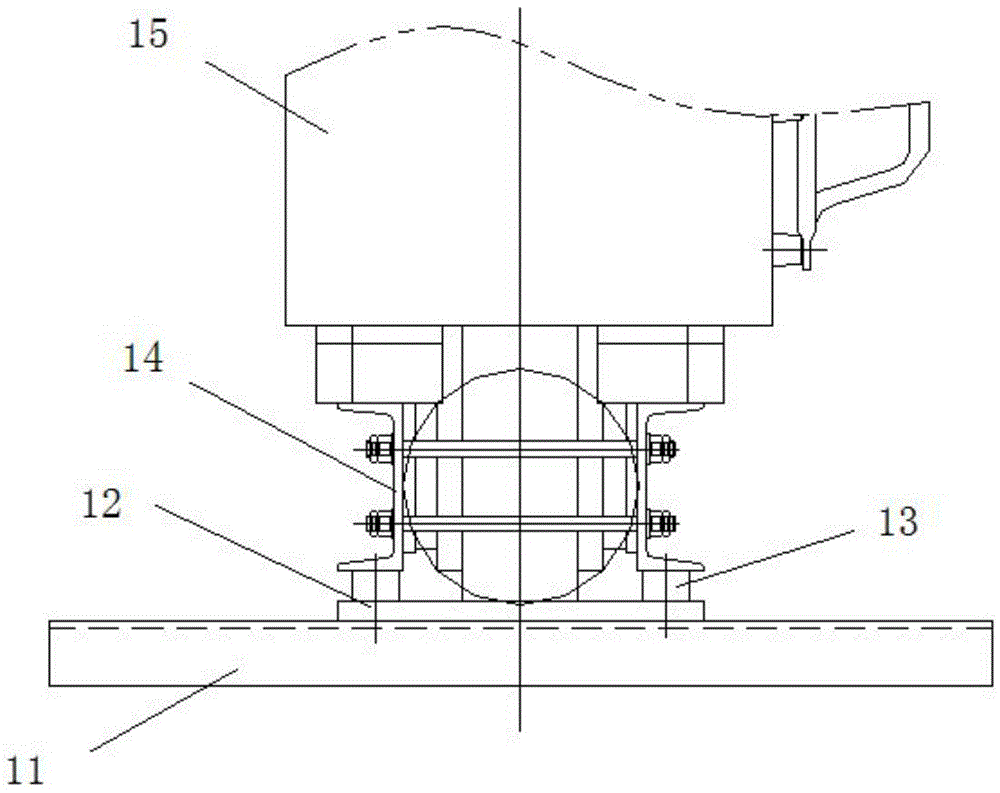

[0019] A support structure for epoxy casting dry-type transformer body, see Figure 4 and Figure 5 , the structure includes a trolley foot 1, a support seat 2, a support foot 3 and a foot insulation 4, the support seat and the support foot are arranged on the trolley foot, and the support foot is located outside the support seat; the support foot is welded by channel steel. The supporting seat is made of bending steel plates, sealing plates and welding. The foot insulation is flatly laid on the upper surface of the support seat; positioning pins are arranged between the trolley feet, the support seat and the foot insulation.

[0020] In the present invention, the original support sleeve structure is changed to support feet welded by channel steel, and the support plane is increased to ensure that the transformer body 5 has sufficient stability after being raised. Thicken the bottom foot insulation to enhance the buffering and noise absorption effect on the transformer body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com