Optical path restriction slit structure for preventing X ray leakage and improving imaging quality

An image quality, X-ray technology, applied in X-ray equipment, electrical components, etc., can solve the problems of heavy metal lead pollution, increase the weight of the whole machine, increase the difficulty, etc., to reduce the influence of stray light, reduce the weight of the whole machine, The effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

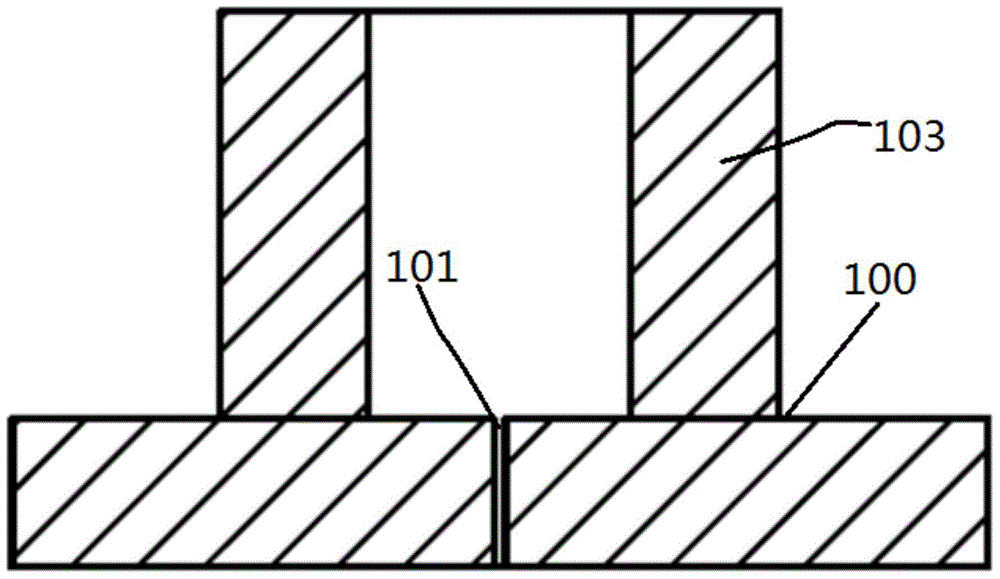

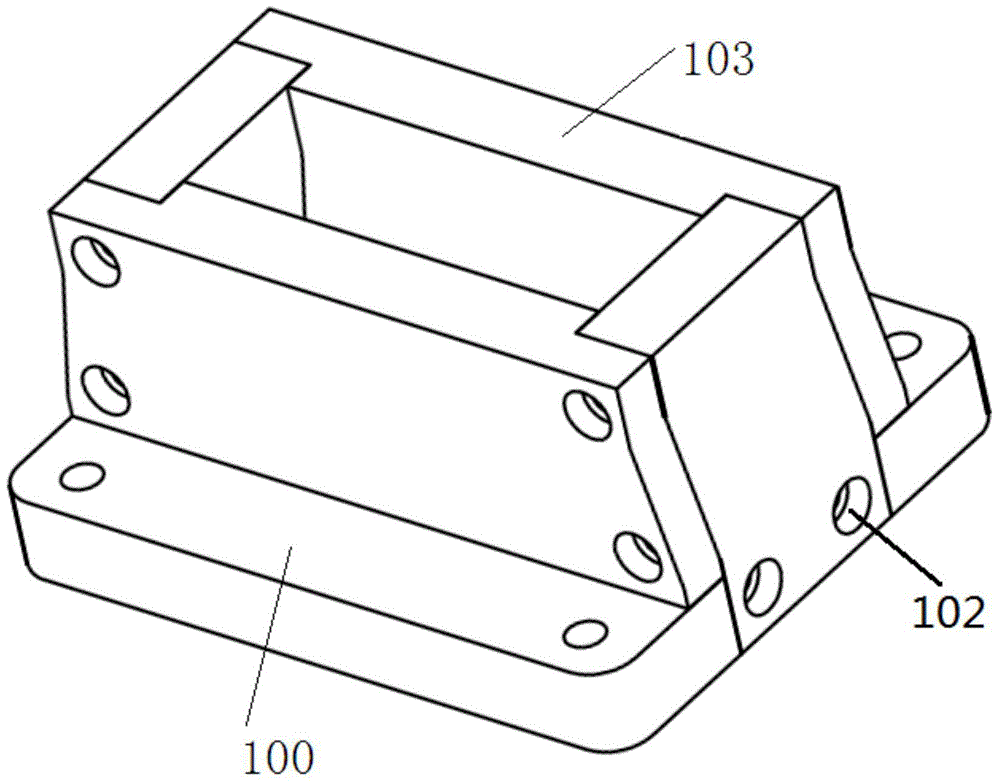

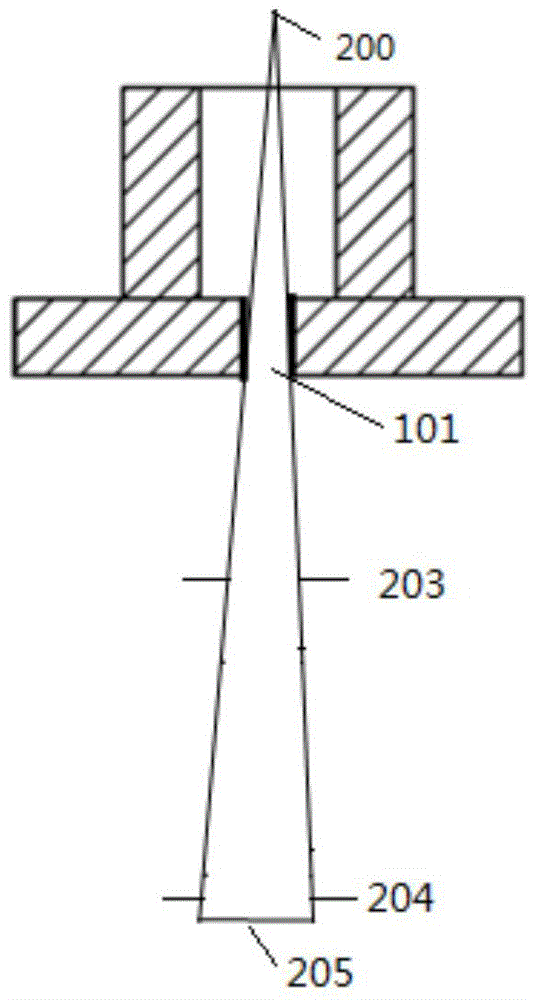

[0023] like figure 1 and figure 2 As shown, the present invention discloses an optical path limiting slit structure that prevents X-ray leakage and improves imaging quality, including a bottom plate 100, side plates 102 and surrounding plates 103, the bottom plate 100 is provided with a slit 101, and the bottom plate 100 1. The side plate 102 and the surrounding plate 103 are fixed by bolts, and the bottom plate 100, the side plate 102 and the surrounding plate 103 are all made of steel material, which is convenient for radiation protection.

[0024] When the maximum operating voltage of the X-ray source is 80 keV, the thickness of the bottom plate 100, side plate 102 and surrounding plate 103 is at least 16 mm; when the maximum operating voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com