Variable geometry turbocharger

A technology of exhaust turbine and supercharger, which is applied in the direction of non-variable pumps, mechanical equipment, engine components, etc., which can solve the problems of turbine performance degradation and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

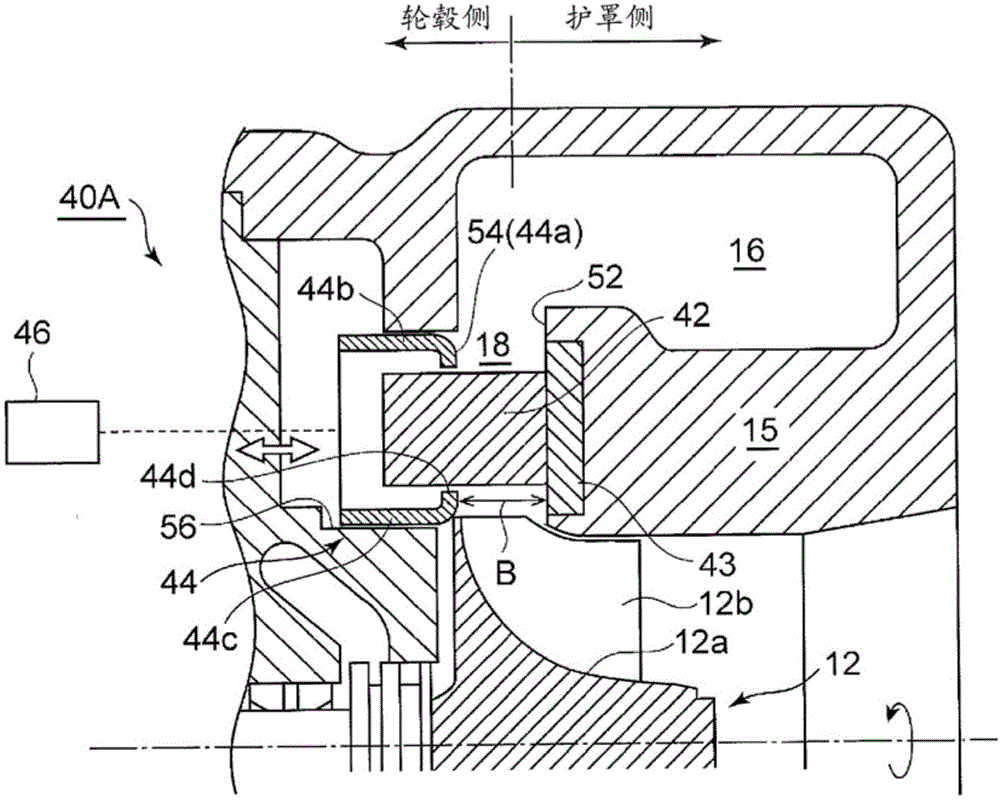

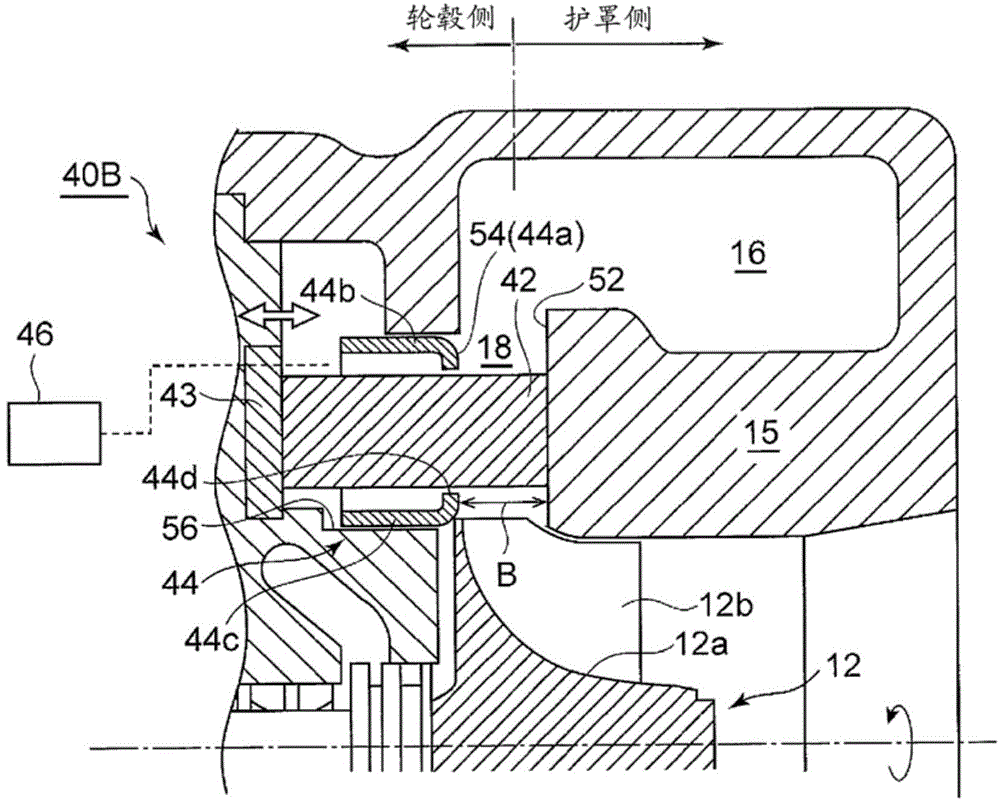

[0091] According to such an embodiment, since the cooling medium can be introduced from the cooling medium introducing mechanism 70 into the internal space 44f of the nozzle wall 44, the nozzle wall 44 can be effectively cooled. Furthermore, since the nozzle wall 44 has a rib portion 44e protruding from the peripheral end portion of the opening portion 44d toward the hub side, the cooling medium introduced into the internal space 44f is less likely to leak to the nozzle portion 18, and the turbine efficiency due to leakage of the cooling medium is prevented. decrease.

[0092] In addition, by forming the through hole 64 inside the nozzle vane 42 Figure 7 In the combination of the illustrated embodiments, the cooling medium introduced into the internal space 44 f flows through the through-holes 64 inside the nozzle vane 42 , so that the nozzle vane 42 can also be cooled simultaneously with the nozzle wall 44 .

[0093] Figure 9 It is a figure which shows the coolant introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com