Atomizing agent for electronic cigarette and electronic cigarette liquid

A technology of atomizing agent and electronic cigarette, which is applied in the fields of atomizing agent for electronic cigarette, atomizing agent for electronic cigarette and electronic cigarette liquid, and can solve the problems of poor matching of heating wire heating temperature, influence of fogging ability, and fogging To avoid problems such as low ability, to avoid hollowness, ensure fluidity, and increase the effect of thick and fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

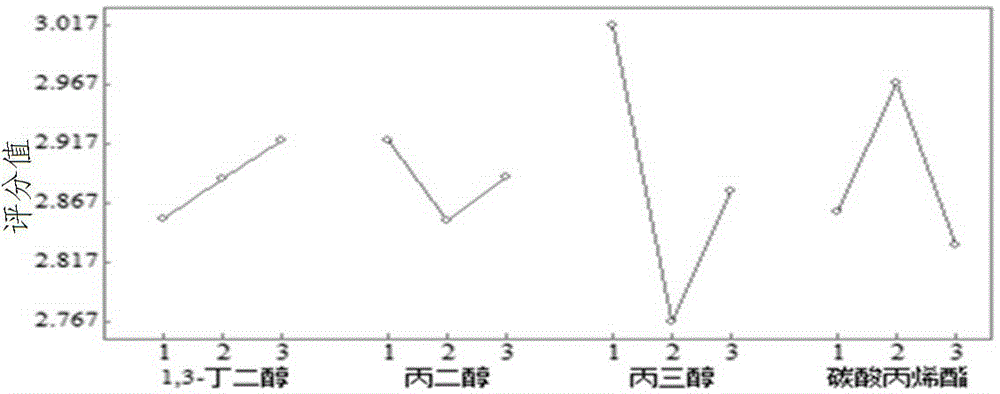

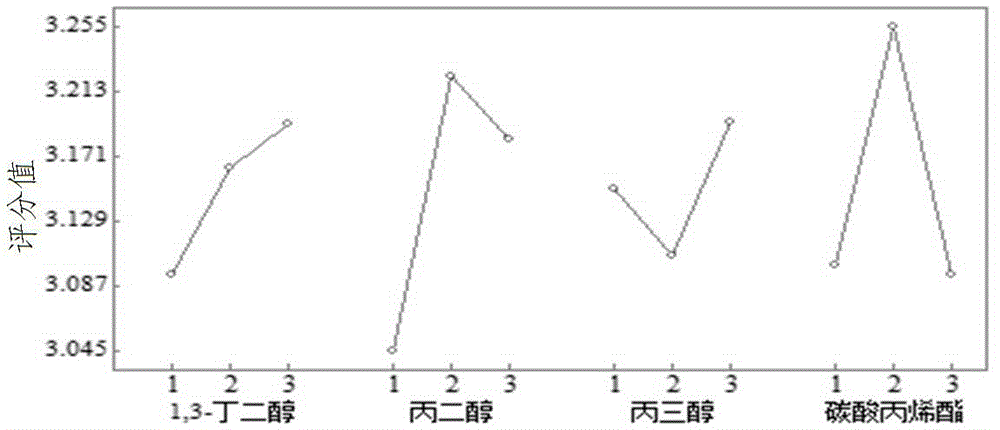

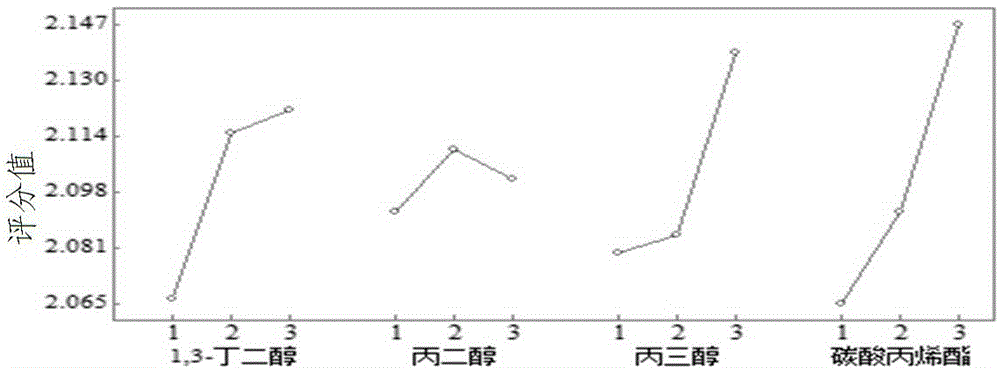

[0029] Embodiment 1: This embodiment is a group of orthogonal experiments. Objective: To use the empirical method to study the effects of different dosages of various components on the sweetness and greasy feeling of electronic cigarette vape, the amount of smoke and other sensory qualities. Method: use L 9 (3 4) of the orthogonal design (see Table 1 for details of the orthogonal design table). Under the condition of a fixed water consumption of 3%, it was studied that three different dosage levels of 1,3-butanediol, propylene glycol, glycerin (ie, glycerol), and propylene carbonate four factors have a strong or weak effect on the sweetness and greasy feeling of e-cigarette smoke , the amount of smoke and other sensory qualities.

[0030] Table 1 Orthogonal design table for the influence of different dosages of ingredients on the sensory quality of e-cigarette smoke

[0031]

[0032] According to the dosage mentioned in Table 1, prepare 9 treatment mother solutions, add...

Embodiment 2

[0052] Embodiment 2: This embodiment is a group of single factor experiments. The optimization experiments were mainly continued on the basis of Example 1 (the processing sample numbers were 12-20). See Table 3 and Table 3 (continued) for the mass percentages of the substances used in each treatment of the e-cigarette agent and its main sensory quality defects. The overall sensory quality of the effect is good.

[0053] Table 3 Mass percentage content of each component of electronic atomization agent

[0054]

[0055] Table 3 (continued) Main sensory quality evaluation table of e-cigarette smoke

[0056]

Embodiment 3

[0057] Embodiment 3: Test the sensory quality under the condition of no water and no ethanol.

[0058] Weigh and mix 1,3-butanediol, propylene glycol, glycerin and propylene carbonate according to the mass percentages of 37%, 15%, 18% and 30% in sequence to form an aerosol, which is evaluated for inhalation.

[0059] Smoking evaluation found that in the case of anhydrous and ethanol-free viscosity-adjusting ingredients, the amount of smoke in the oral cavity meets the requirements, but the filling of the smoke is not good when exhaled from the nasal cavity. Compared with the samples added with water and / or ethanol, the mouth is not comfortable and clean enough, with a slight astringent feeling. Therefore, it is preferable to add appropriate amount of water and / or ethanol to the viscosity adjusting component in addition to propylene carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com