Upwards-floating type oil-water separator

A technology of oil-water separator and separation container, applied in liquid separation, separation method, chemical instrument and method, etc., can solve the problems of insufficient utilization rate of cutting fluid, low working efficiency of belt-type oil-water separator, incomplete separation, etc. , to save space, reduce the number of water tank maintenance, and not easy to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

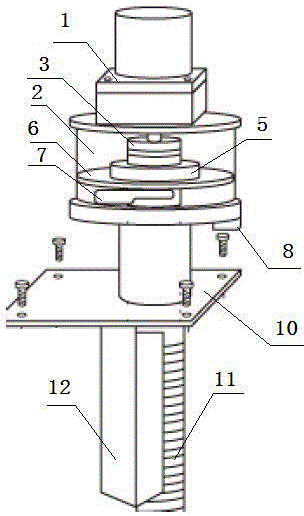

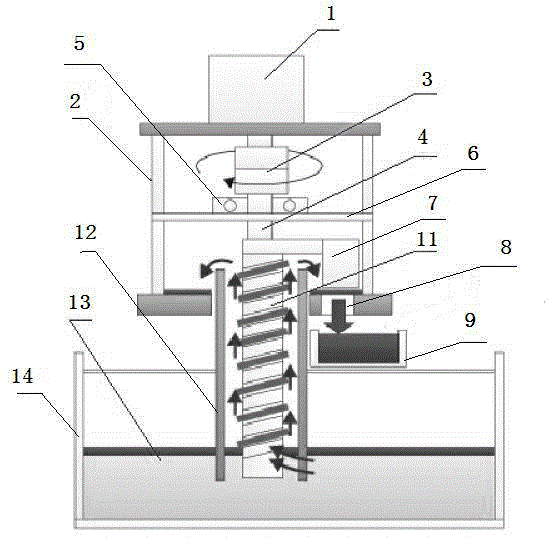

[0015] Such as figure 1 , 2 As shown, a floating oil-water separator according to the present invention includes a motor 1, a separation container 2, a coupling 3, a partition 6, a sealing plate 5, a rotating shaft 4, an oil scraper 7, a screw rod 11, a retaining Oil plate 12, connection plate 10, oil receiving box 9.

[0016] The motor 1 is fixed on the upper surface of the separation container 2, electrically connected to the coupling 3; the partition plate 6 is located inside the separation container 2, and the separation container 2 is divided into upper and lower layers. There is a circular through hole, the rotating shaft 4 passes through the circular through hole of the partition 6 and is connected with the screw rod 11, the sealing plate 5 is located on the partition 6, and is nested and installed on the rotating shaft 4 to prevent floating The oil splashes to the upper layer of the separation container 2 through the gap between the circular through hole of the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com