Weathering type stone coal vanadium ore beneficiation method

A mineral processing method, stone coal vanadium technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of ineffective dissociation and enrichment of vanadium-containing minerals, so as to avoid ore mudification , reduce viscosity and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with embodiments.

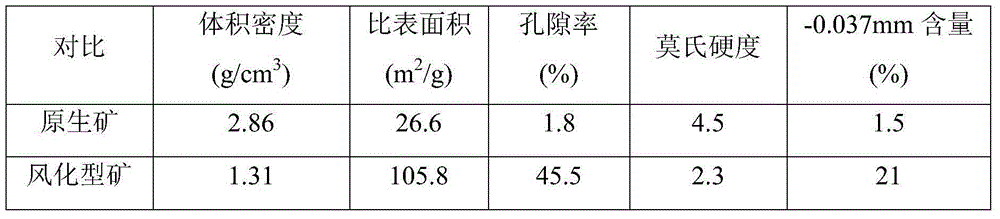

[0022] The original ore is a weathered low-grade stone coal vanadium mine in Hubei. The recyclable valuable components in the ore are mainly vanadium pentoxide, and the content of vanadium pentoxide in the ore is 0.78%. The raw ore composition of the ore is shown in Table 1 below; the weathering physical characteristics of the raw ore are shown in Table 2 below.

[0023] Table 1 Composition of raw ore

[0024] the element

V 2 o 5

al 3 o 2

SiO 2

Na 2 o

K 2 o

CaO

MgO

CaF 2

Ba

content

0.78

6.39

36.73

0.13

1.70

14.09

9.25

1.43

0.29

the element

Ti

Fe

Cu

Pb

Zn

S

As

C

content

0.42

3.47

0.048

0.07

0.095

0.0014

0.12

7.65

[0025] Table 2 Comparison of parameters between primary ore and weather...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com