Dismantling and classifying system of waste liquid crystal display

A technology of liquid crystal display and classification system, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve the problems of operator injury accidents, rising labor costs, low efficiency, etc., to avoid noise and dismantle The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

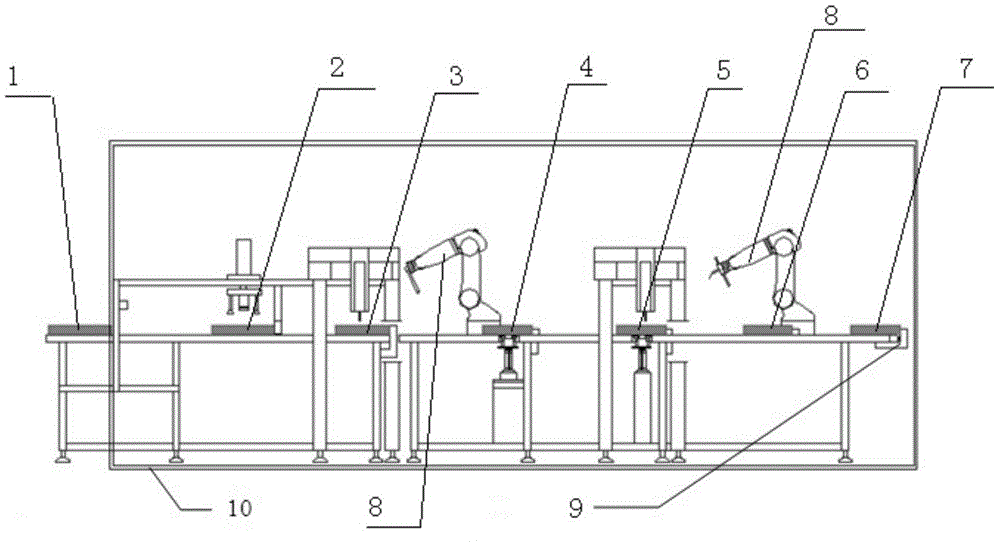

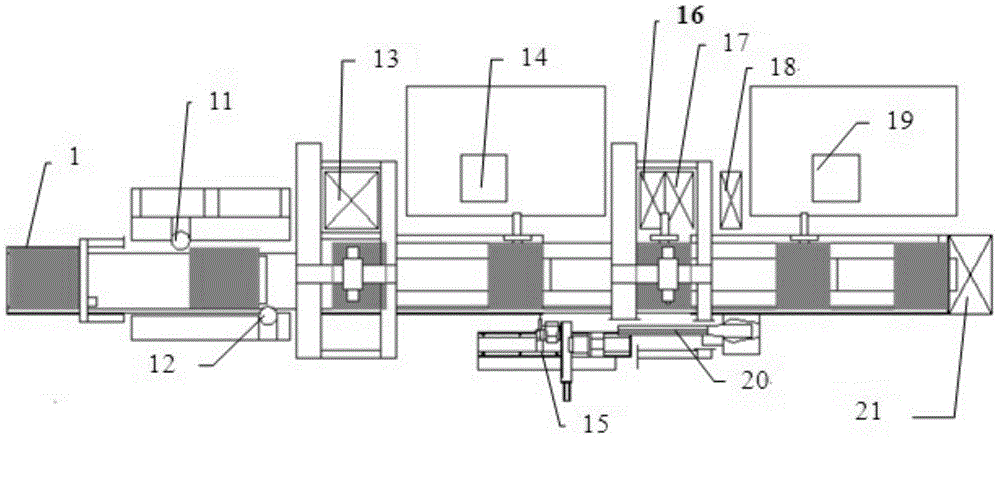

[0011] figure 1 Dismantling and sorting system for waste liquid crystal displays (front view), such as figure 1 As shown, the present invention includes the following stations from upstream to downstream: loading station 1, outer cover cutting station 2, outer cover opening and separation station 3, laser cutting and screwing station 4, outer shielding cover Recycling and main control circuit board separation and recycling station 5, inner shielding cover separation and recycling station 6, liquid crystal panel control circuit board and liquid crystal panel separation and recycling station 7; the above stations are connected by conveyor belts to realize assembly line work.

[0012] Cutting station 2, outer cover opening and separation station 3, laser cutting and screwing station 4, out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com