Manufacturing method of aluminum, titanium and boron alloy rod

A technology of aluminum-titanium-boron and alloy rods, which is applied in the field of preparation of aluminum-titanium-boron alloy rods, can solve the problem of not involving aluminum-titanium-boron alloy rods, which cannot meet the requirements of semi-continuous casting and continuous casting and rolling production of pure aluminum and aluminum alloys, powdered The use of refiner is inconvenient and other problems, to achieve the effect of small size, fine grain structure, and avoid trachoma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

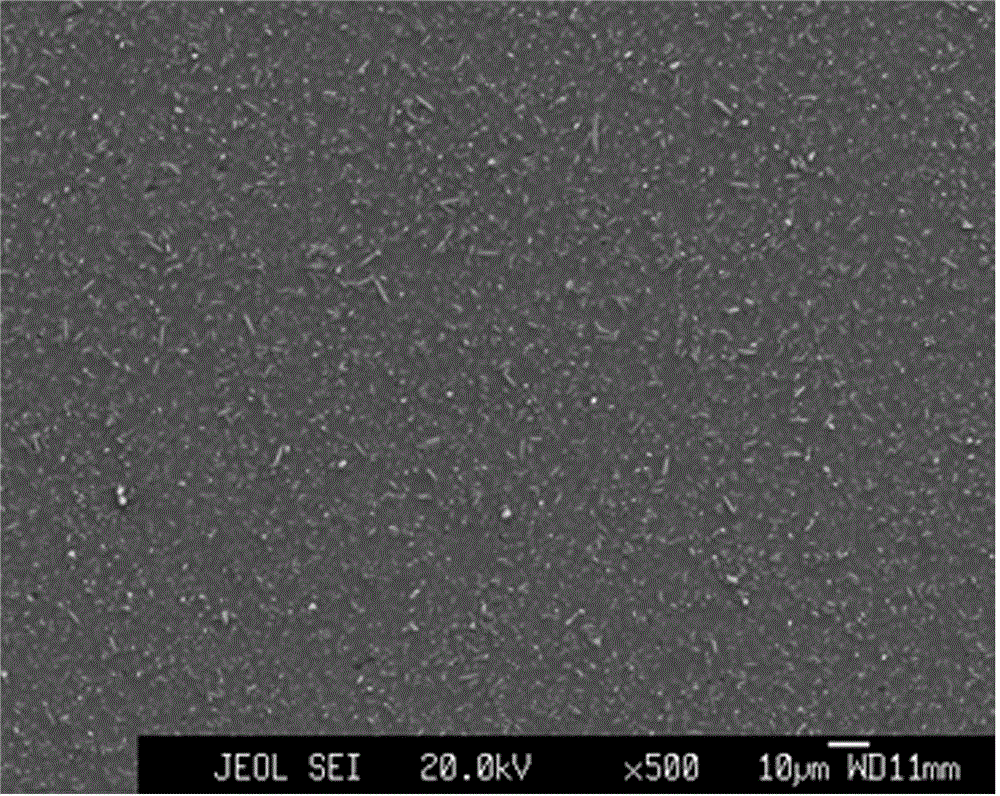

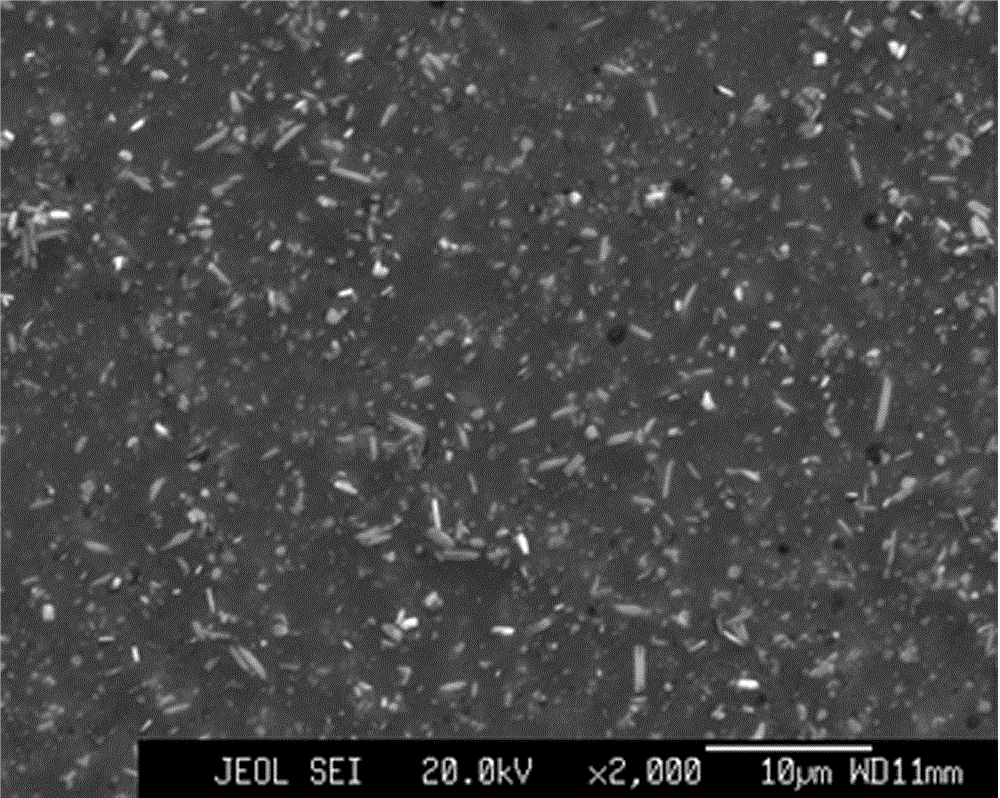

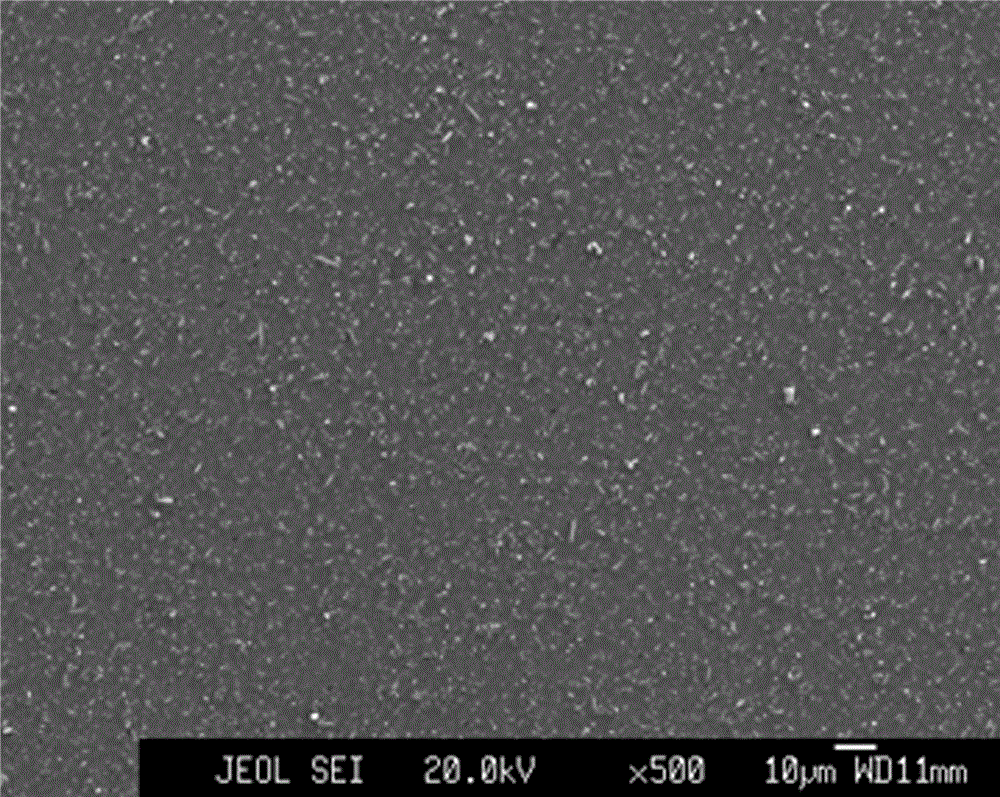

Image

Examples

Embodiment 1

[0035] The present invention is used to prepare aluminum-titanium-boron alloy rods with 5% Ti element content and 1% B element content. Extruder, the preparation method is as follows:

[0036] Step 1: Heat and melt the aluminum ingot in a medium-frequency induction furnace and raise the temperature to 875°C, then add 25% potassium fluorotitanate and 11.5% potassium fluoroborate by the mass of the aluminum ingot, stir for 80 minutes, and remove the surface of the alloy liquid the scum to obtain the aluminum-titanium-boron alloy liquid;

[0037] The second step: transfer the aluminum-titanium-boron alloy liquid to the atomizing powder making machine, atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 810°C, and the atomization nitrogen pressure is 2.5MPa;

[0038] Step 3: Screen the aluminum-titanium-boron alloy powder with a 100-mesh vibration screening machine to obtain aluminum-titanium-boron alloy po...

Embodiment 2

[0051] The aluminum-titanium-boron alloy rod with 4.5% Ti element content and 0.8% B element content is prepared by the present invention, and the main equipments are medium frequency induction melting furnace, atomizing pulverizer, vibration screening machine, cold isostatic pressing machine and horizontal Extruder, the preparation method is as follows:

[0052] Step 1: Heat and melt the aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 850°C, then add 22.5% potassium fluorotitanate and 9.2% potassium fluoroborate by the mass of the aluminum ingot, stir for 60 minutes, and remove the surface of the alloy liquid the scum to obtain the aluminum-titanium-boron alloy liquid;

[0053] The second step: transfer the aluminum-titanium-boron alloy liquid to the atomizing powder making machine, atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 800°C, and the atomization ...

Embodiment 3

[0060] The present invention is used to prepare aluminum-titanium-boron alloy rods with a Ti content of 5.5% and a B content of 1.2%. Extruder, the preparation method is as follows:

[0061] Step 1: Heat and melt the aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 900°C, then add 27.5% potassium fluorotitanate and 13.7% potassium fluoroborate by the mass of the aluminum ingot, stir for 90 minutes, and remove the surface of the alloy liquid the scum to obtain the aluminum-titanium-boron alloy liquid;

[0062] The second step: transfer the aluminum-titanium-boron alloy liquid to the atomizing powder making machine, atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 820°C, and the pressure of atomized nitrogen is 3MPa;

[0063] Step 3: Screen the aluminum-titanium-boron alloy powder with a 100-mesh vibration screening machine to obtain aluminum-titanium-boron all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com