Automatic welding device for connection lugs of barrel body

An automatic welding and connecting ear technology, which is applied in auxiliary devices, welding equipment, metal processing, etc., can solve the problems of inaccurate connecting ear position, low work efficiency, burn workers' palms, etc., achieve simple structure, improve work efficiency, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

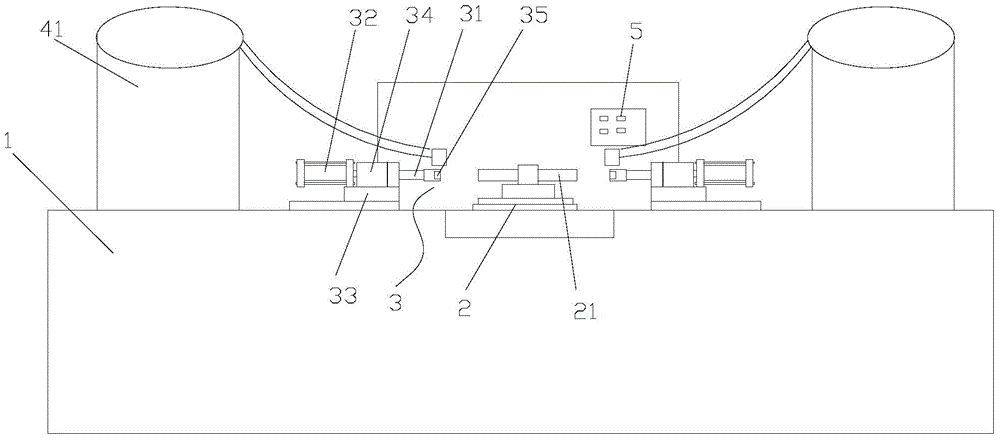

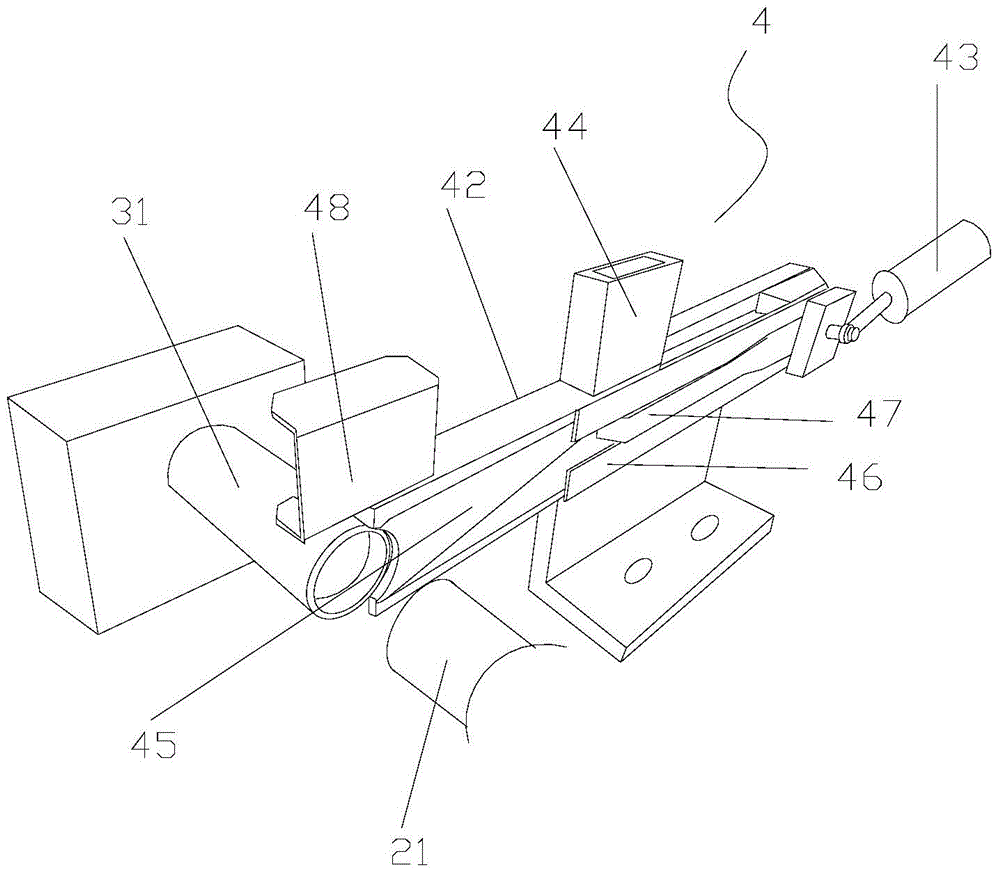

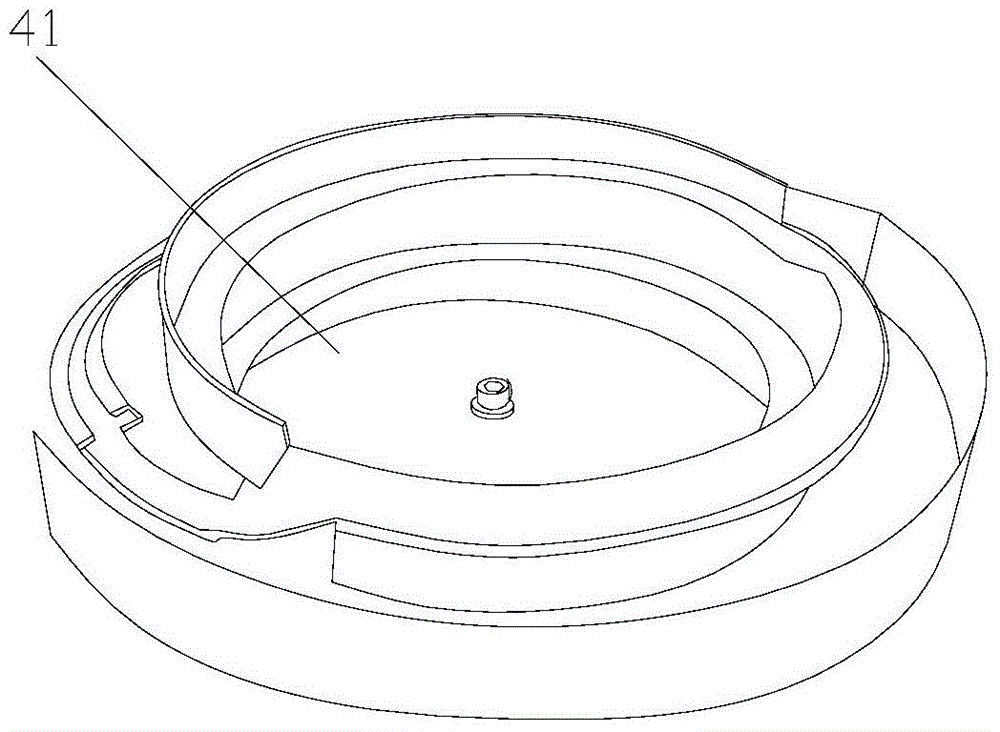

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a barrel connecting ear automatic welding device includes a frame 1, a limit table 2, and a welding mechanism 3 arranged on the frame. The welding mechanism includes a heating welding head 31 and a welding cylinder 32. The welding mechanism is two groups, and the limit platform is located between the two groups of welding mechanisms; the welding cylinder is fixed on the fixed seat 33, and the fixed seat is provided with a sliding sleeve 34, and the piston rod of the welding cylinder passes through Through the sliding sleeve, the front end of the piston rod of the welding cylinder is connected to the heating welding head, and the heating welding head is provided with an accommodating groove 35 for placing connecting ears; Between the two heating welding heads, two positioning pos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap