Novel wood boring machine

A woodworking drill, a new type of technology, applied in the direction of fixed drilling machines, etc., can solve the problems of large rotational inertia, impracticality, and low work efficiency, and achieve the effects of reducing investment funds, reasonable structural design, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

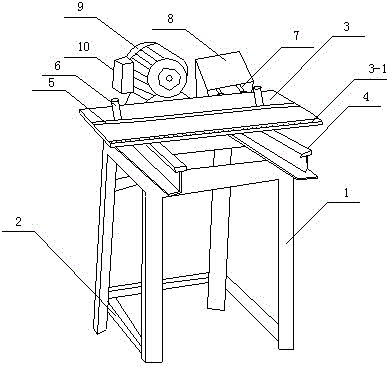

[0016] Embodiment 1: a plank with a width of 1 meter is placed on the workbench 3, the positioning pin bolt 6 is used to slide on the chute 5, the plank is fixed and positioned, the working motor 9 is turned on, and the plank is drilled with a drill bit 10, and the drill bit 10 is used to drill the plank. The waste debris produced by the hole is cleaned into the waste collection box 8 by the cleaning tool. When the length of the plank needs to be measured, it can be measured by placing it on the side of the scale layer 3-1, and the workbench 3 is slidably connected with the track 4, which can Adjust the distance between the workbench 3 and the drill bit 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com