Vervain family softening method

A technology of Vitex and treatment liquid, which is applied in reed/straw treatment, wood processing equipment, manufacturing tools, etc. It can solve problems such as difficult weaving, unrecoverable, and affecting normal use, so as to enhance the use performance, improve product quality, and corrosion resistance. Sexual Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method for softening Vitex, comprising the steps of:

[0012] (1) Prepare treatment solution A, by weight, heat 180 parts of water, 6.5 parts of glycerin, 3.6 parts of pine nut oil, and 3.7 parts of tributyl phosphate to 35°C to make them fully mixed, then add 14.5 parts of urea, potassium nitrate 5.2 parts, make it fully mixed and dissolved to obtain treatment solution A;

[0013] (2) Soak the Vitex twigs in a treatment solution at 35-40°C for 15-20 hours, then remove the Vitex twigs and weave them;

[0014] (3) For the treatment of treatment solution B, mix 3.8 parts of polyethylene glycol with 75 parts of water and stir at 42-45°C to fully dissolve it, then put the woven Vitex twig products into it for soaking, soak for 2 hours, and then Add 3.5 parts of sodium bicarbonate to dissolve it, continue to soak for 3 hours, remove it, and rinse it with clean water.

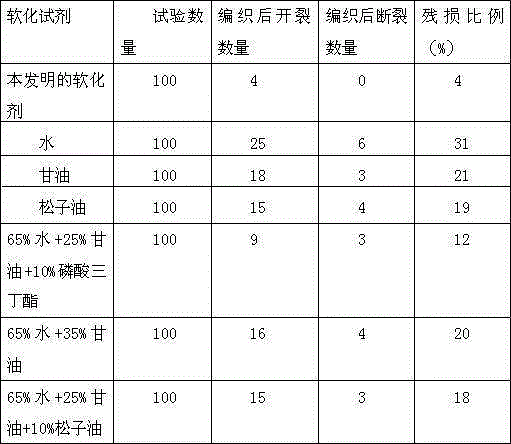

[0015] Use treatment solution A of the present invention to process, use 700 Vitex vitex of the same ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com