Pink light conversion multi-functional heliogreenhouse film

A solar greenhouse and multi-functional technology, applied in the field of agricultural shed film, can solve the problems that cannot be used in the production of plastic greenhouses and greenhouses, the fast attenuation speed of inorganic light-transforming agents, and the low transmittance of red and orange light, so as to speed up photosynthesis Efficiency, improvement of key quality indicators, improvement of yield and effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

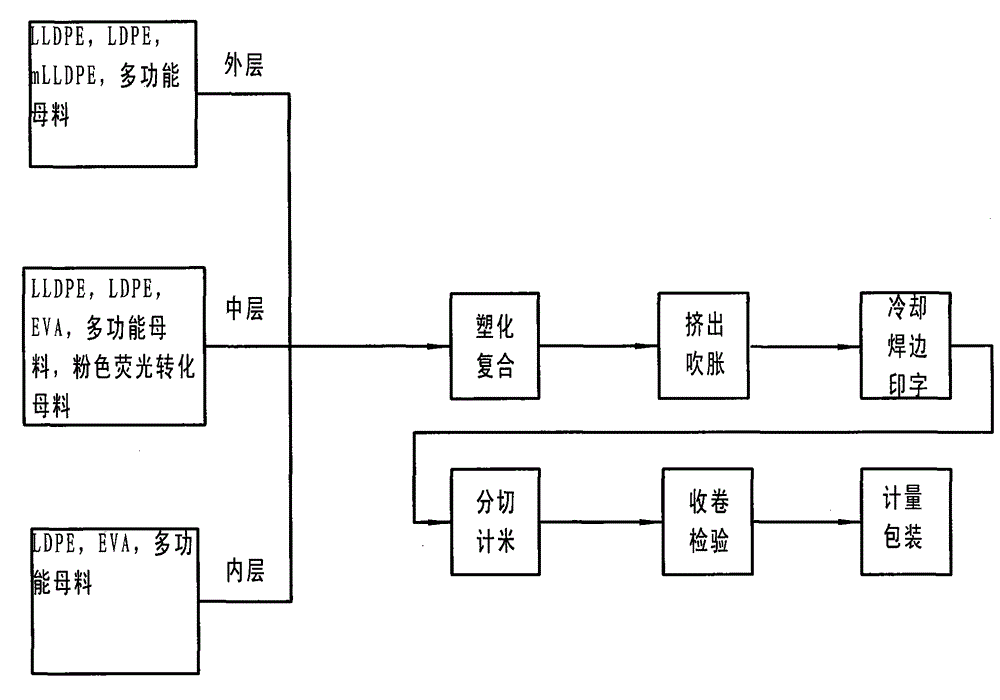

[0008] A pink light-converting multifunctional sunlight greenhouse film, made of the following raw materials in weight percentage:

[0009] Outer layer: LLDPE 40%, LDPE 28%, mLLDPE 23%, multi-functional masterbatch 9%; among them: the melt flow rate of LLDPE is 0.8-1.0g / 10min, the melt flow rate of LDPE is 0.3-1.0g / 10min, mLLDPE The melt flow rate is 0.7-1.0g / 10min;

[0010] Middle layer: LLDPE16%, LDPE27%, EVA36%, multi-functional masterbatch 14%, pink fluorescent conversion masterbatch 7%; among them: the melt flow rate of LLDPE is 2.0-3.0g / 10min, and the melt flow rate of LDPE is 1.0 -2.0g / 10min, the melt flow rate of EVA is 1.0-2.0g / 10min, and the VA content is 12-14%;

[0011] Inner layer: 30% LDPE, 55% EVA, 15% multifunctional masterbatch; among them: the melt flow rate of LDPE is 1.0-2.0g / 10min, the melt flow rate of EVA is 1.0-2.0g / 10min, and the VA content is 12 -14%.

[0012] LLDPE with a melt flow rate g / 10min of 1.0-3.0 is produced by PetroChina Lanzhou Petroche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com