Deformable aircraft leading edge slat and method for designing the same

A leading-edge slat and aircraft technology, applied to aircraft parts, aircraft control, transportation and packaging, etc., can solve problems such as endangering flight safety and aircraft stalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

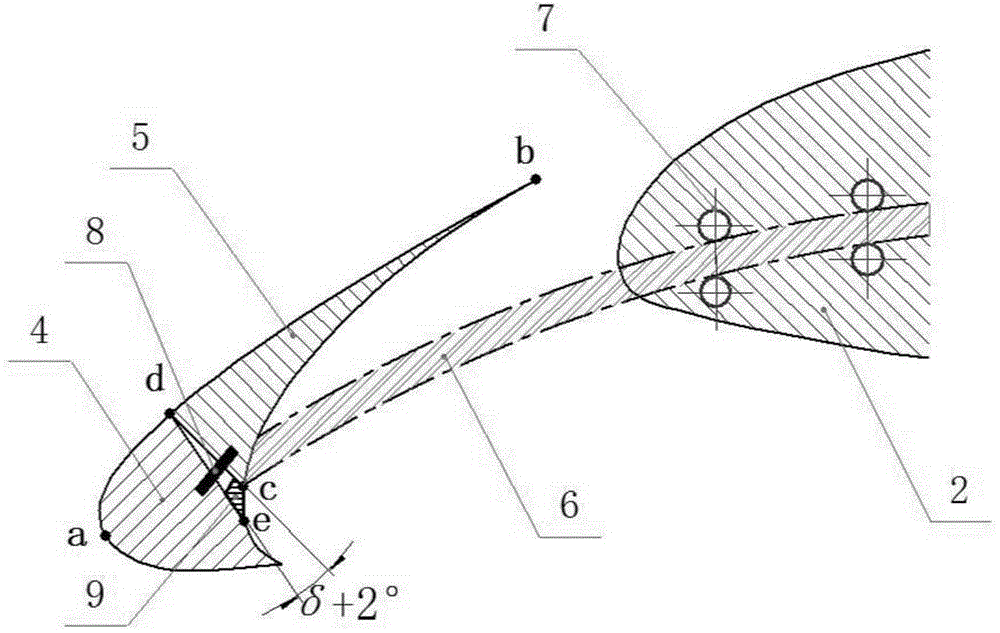

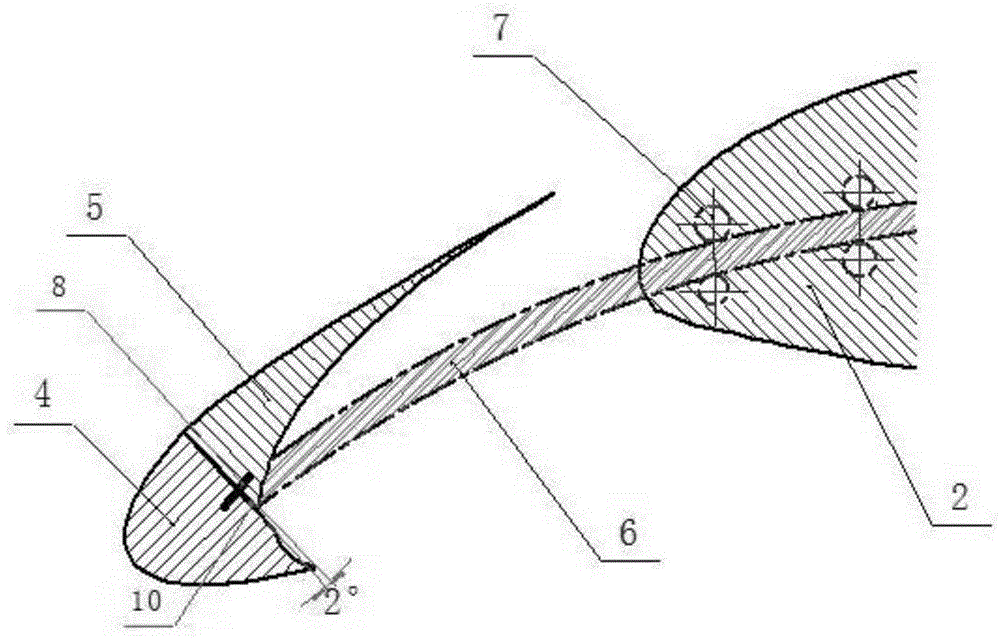

[0087] This embodiment is a deformable leading-edge slat of an aircraft, and the stall characteristics of the aircraft are improved by changing the shape of the leading-edge slat.

[0088] In this embodiment, a certain type of aircraft is taken as an example to describe the technical solution of the deformable leading edge slat of the aircraft.

[0089] The leading edge of the wing of a certain type of aircraft adopts a fixed shape leading edge slat, and the fixed shape leading edge slat adopts the prior art. This embodiment is obtained after improving the fixed shape leading edge slat of the certain type of aircraft.

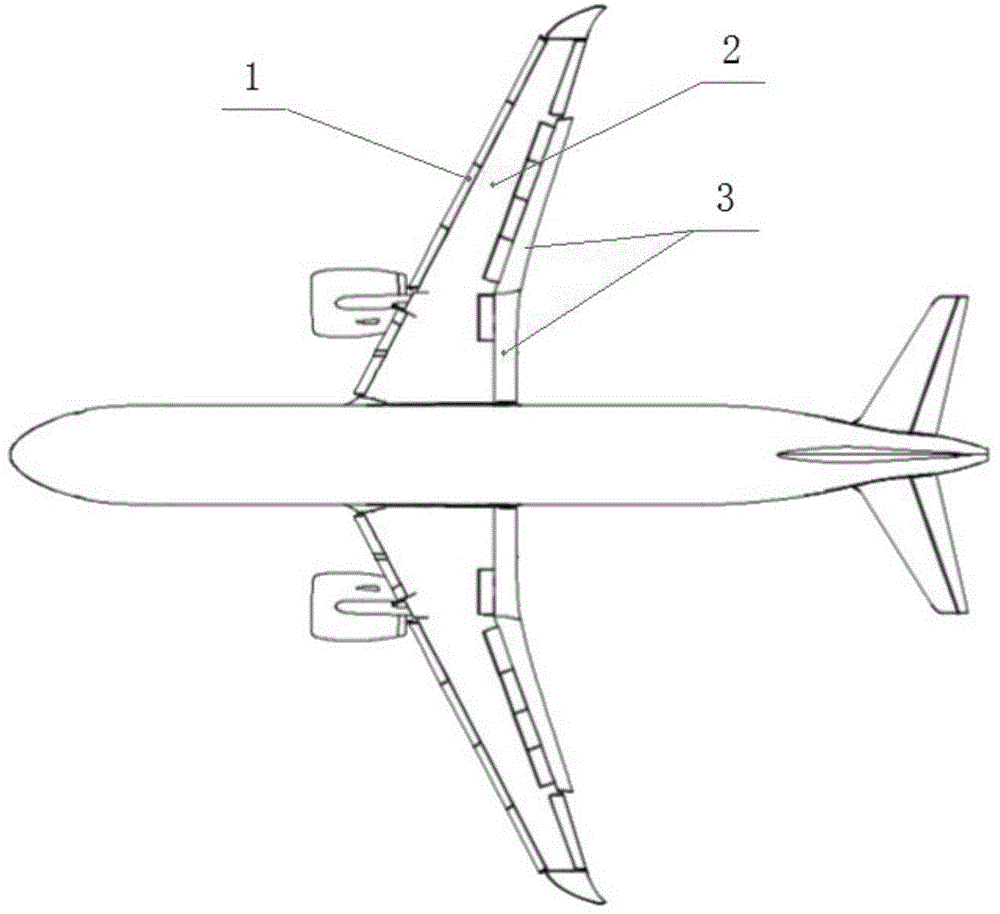

[0090] as attached figure 1 As shown, the aircraft adopts the combination mode of leading edge slat 1, main wing section 2 and trailing edge flap 3 during takeoff / landing to obtain high lift required for takeoff / landing. The leading edge slat in the prior art is composed of an inner section and an outer section, located at the leading edge of the wing and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com