Construction device and construction method of cement slurry retaining wall implanted pipe pile with long helical drilling

A technology of long auger drilling and construction equipment, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as easy insertion and deviation of steel cages, large extrusion force of pipe pile soil, and pollution of the site. Achieve the effect of convenient pile driving process, increase storage space, and avoid disorderly discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and specific embodiments.

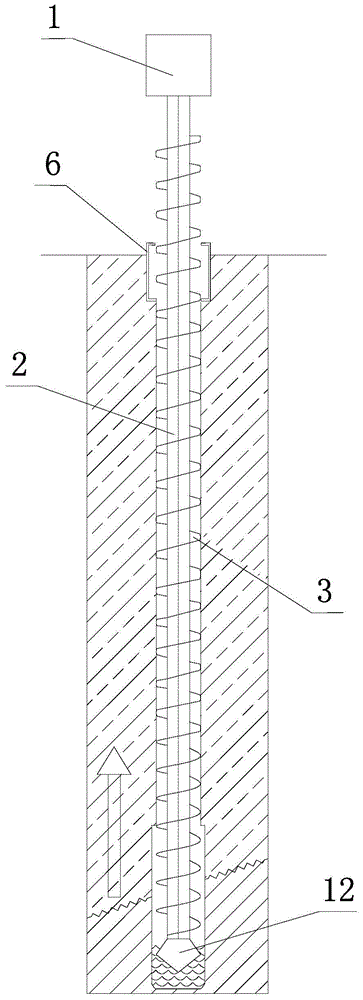

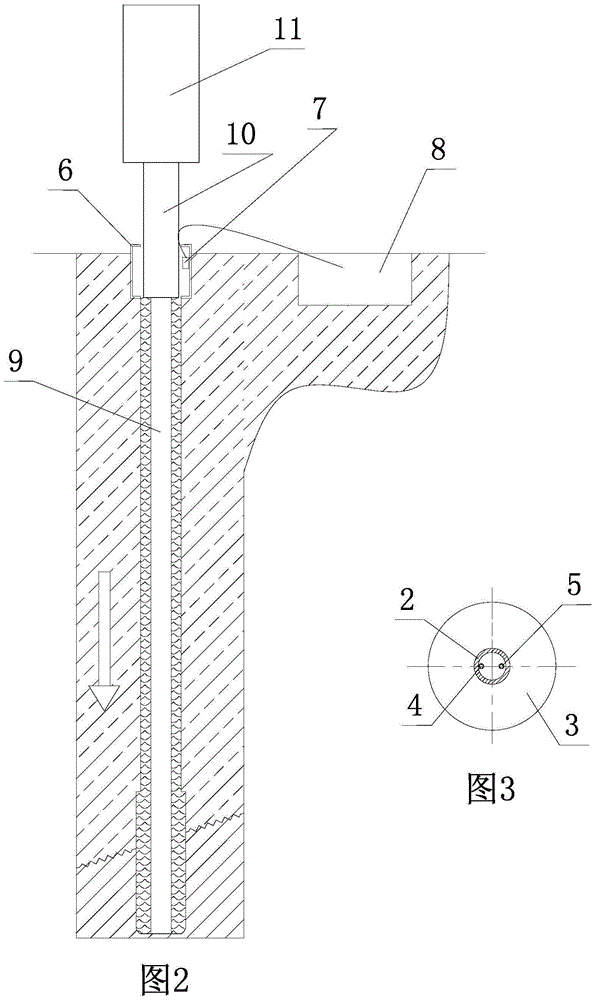

[0024] Such as figure 1 , Figures 2 and 3, the construction device of the long spiral bored cement slurry wall-protected implanted pipe pile of the present invention includes a pile frame, a power head 1, a drill rod 2, an atmospheric pressure grouting pump, and a high pressure grouting pump , The high-pressure grouting pipe 5, the steel sleeve 6, the slurry suction pump 7 and the liquid storage tank 8 arranged in the drill pipe 2.

[0025] The power head 1 is installed on the pile frame, the drill rod 2 is installed below the power head 1, the bottom end of the drill rod 2 is a drill tip 12, and the outer circumference of the drill rod 2 is provided with spiral blades 3 from top to bottom. The drill pipe 2 is provided with a normal pressure grouting pipe 4, the top of the normal pressure grouting pipe 4 is connected to the normal pressure grouting pump through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com