Method for finding feasible prestress of cable-pole structure

A prestressing and initial prestressing technology, applied in the direction of building components, building structures, special data processing applications, etc., can solve the problems that the structural load cannot be considered, has not been discovered, and the external load and self-weight of the structure cannot be considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

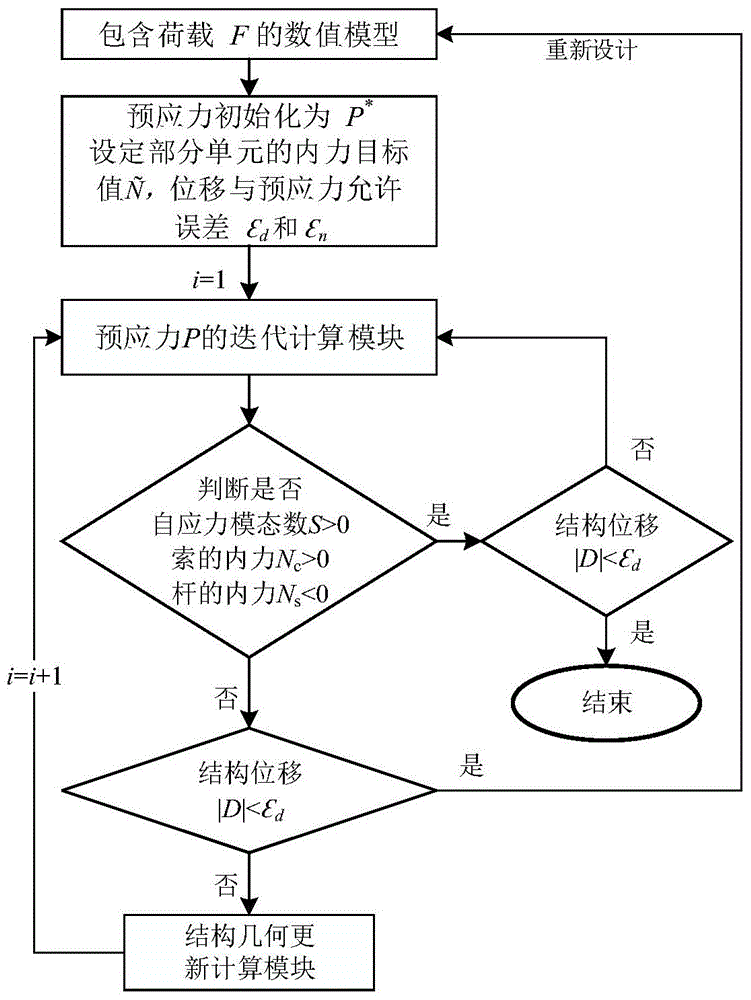

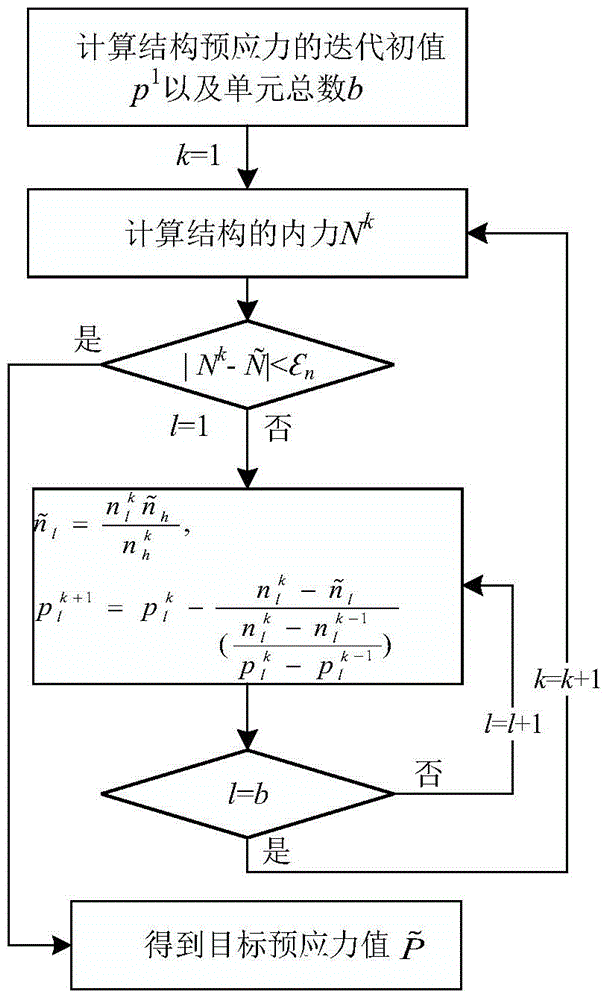

[0038] combine Figure 1~4 , the present invention comprises the following steps:

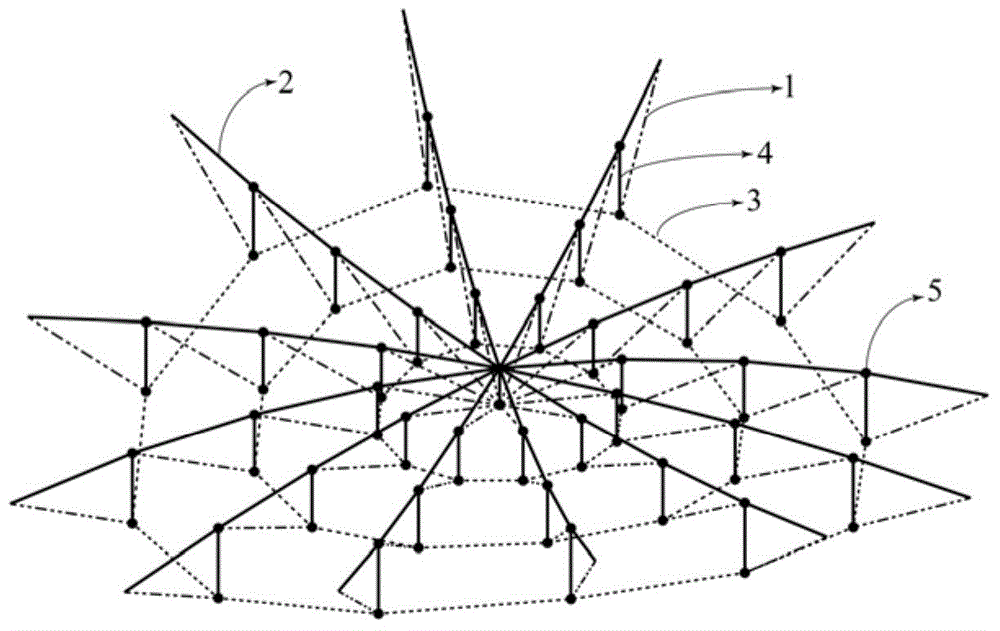

[0039] Step 1: According to geometry X i Establish a numerical model of the cable-strut structure consisting of the lower cable 1, the upper cable 2, the ring cable 3 and the pressure rod 4, and apply all possible loads (F) 5 to the structure; The prestress of oblique cable 2, ring cable 3 and compression rod 4 is initialized to P * =[P c P s ], where the prestress of lower cable 1, upper cable 2, and ring cable 3 is any value greater than zero (P c >0), the prestress of strut 4 is any value less than zero (P s n and displacement calculation error ε d , and according to the design requirements, set the internal force target value of part of the lower cable 1, the upper cable 2, the ring cable 3 or the pressure rod 4 N = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com