Surface deviation detection device and method based on polarization interference

A technology of deviation detection and surface shape, applied in the detection of local deviation, astigmatism deviation, non-destructive testing of spherical lens curvature radius deviation, to achieve the effect of high contrast, reduce errors and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

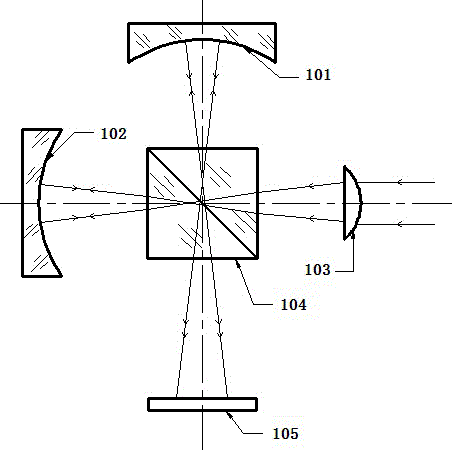

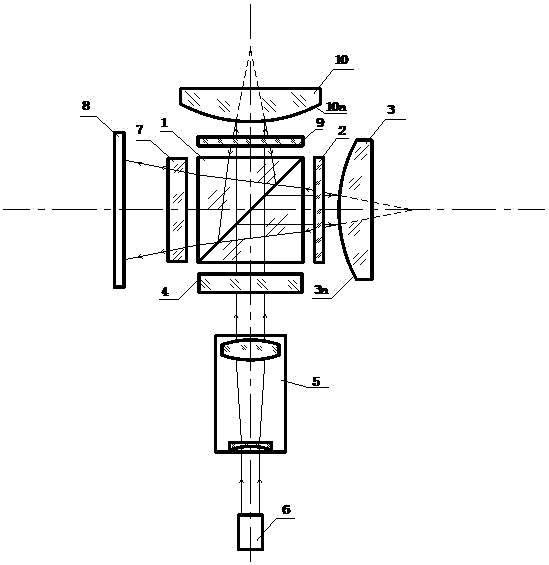

[0021] like Figure 1~2 As shown, the method scheme of the present invention is that the device used in the detection method is a polarization beam splitter 1 (the glued surface is coated with a polarization splitting dielectric film) formed by gluing the slopes of two equilateral rectangular prisms. A laser beam expander 5 with fixed positioning, a fixed detection laser light source 6 directly below the laser beam expander 5, and a polarizer 4 are arranged between the polarization beam splitter 1 and the detection laser light source 6, and the polarization beam splitter 1 The first 1 / 4 wave plate 2 with a fixed position on the right, the lens to be tested 3 on the right of the first 1 / 4 wave plate 2, the receiving screen 8 with a fixed position on the left of the polarization beam splitter 1, and The polarizer 7 is set at any positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com