A fault location device for oil-immersed transformer based on fiber Bragg grating

An oil-immersed transformer, Bragg grating technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large positioning error, transformer failure, time-consuming and labor-intensive, etc., to improve measurement accuracy, short monitoring time, prevent The effect of further exacerbating the failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

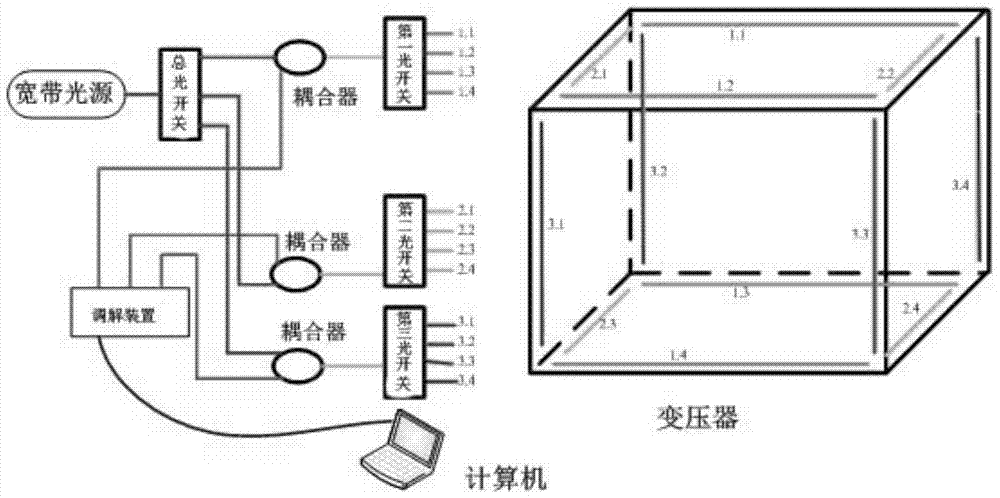

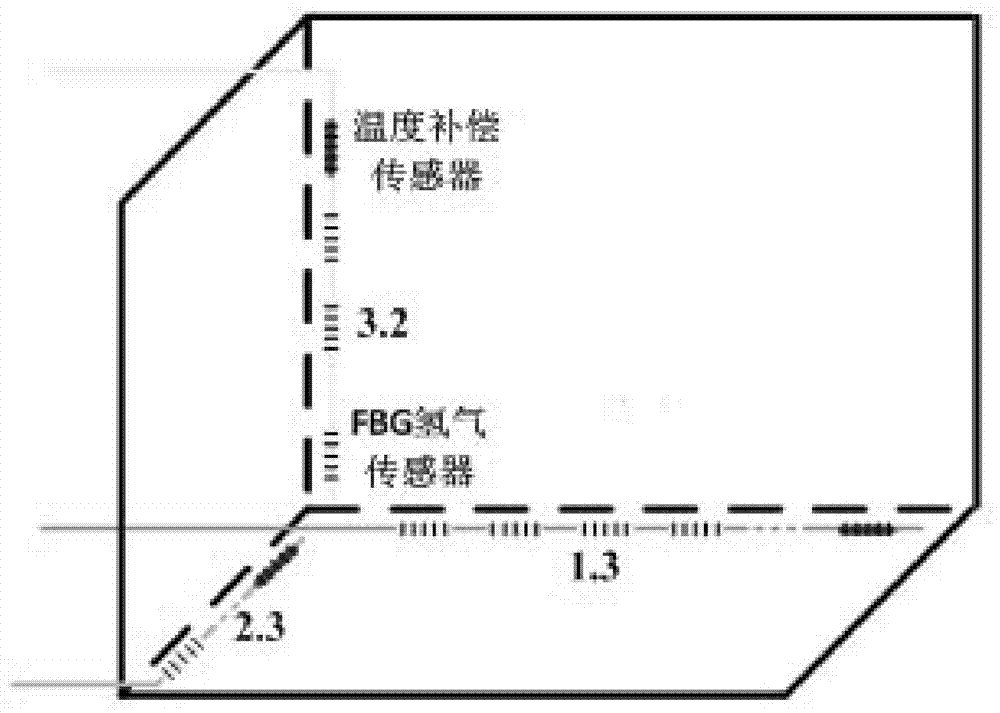

[0034] The present invention proposes a fault location device for an oil-immersed transformer based on an optical fiber Bragg grating, which will be described below in conjunction with the accompanying drawings.

[0035] figure 1 Shown is a schematic diagram of a fault location device in transformer oil. figure 2Shown is the three-dimensional layout of the sensors in the transformer cavity. In the figure, the oil-immersed transformer fault location device of the optical fiber Bragg grating uses a palladium-plated silver alloy film as a hydrogen sensor for dissolving hydrogen in oil, specifically palladium-silver plating on the grid area of the optical fiber Bragg grating The alloy film is used as a fiber Bragg grating hydrogen sensor for dissolving hydrogen in oil. Multiple fiber Bragg grating hydrogen sensors are welded through single-mode optical fibers and arranged on each surface of the transformer cavity to realize the detection of dissolved hydrogen in the transforme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com